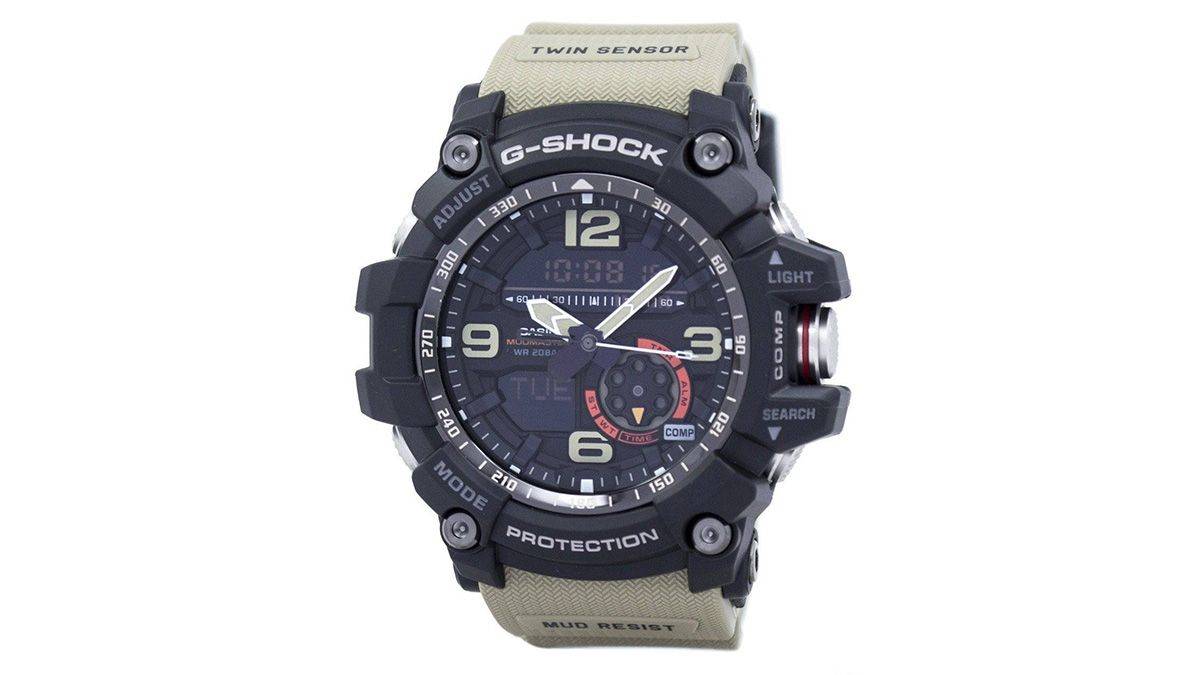

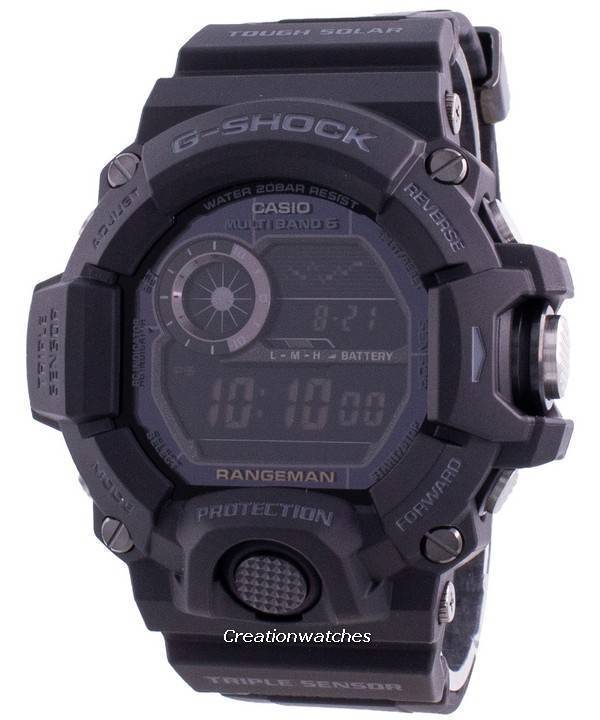

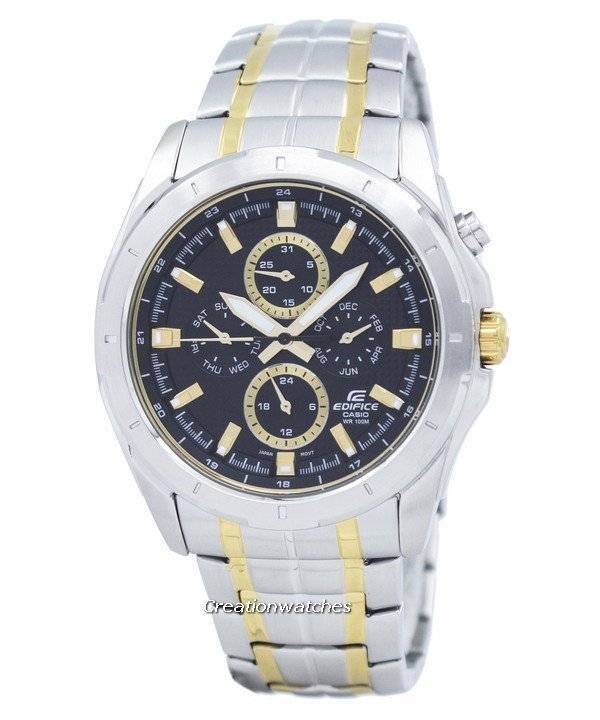

Painful as it may sound, big metal watches are slowly losing attention; it’s the sleek types that are eating into their share. There are always certain clans who like the heft and bulk; we’re not talking about them. Our focus is on general users, not watch collectors and aficionados. The former ones might find this discussion helpful.

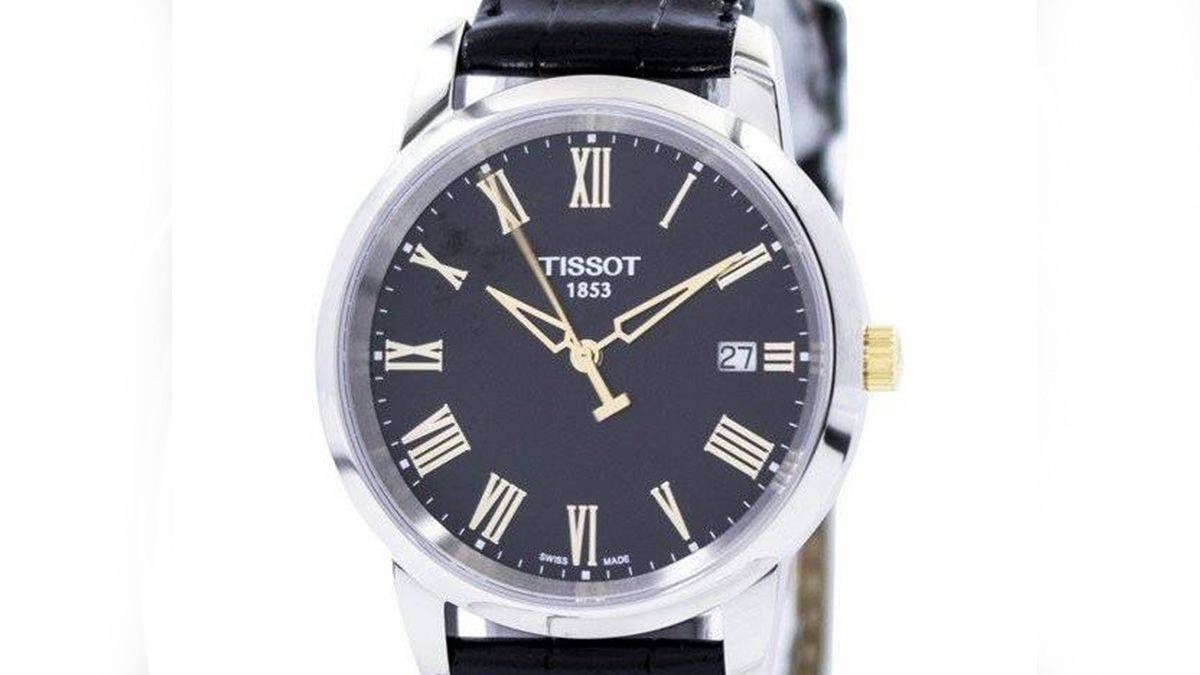

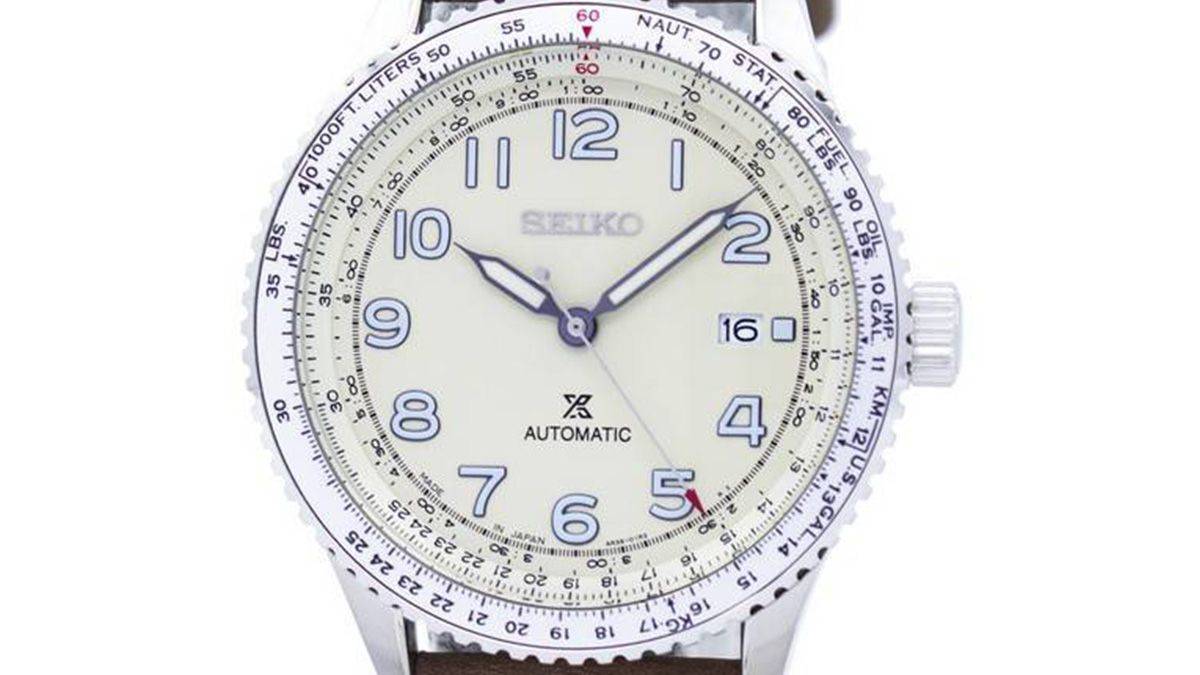

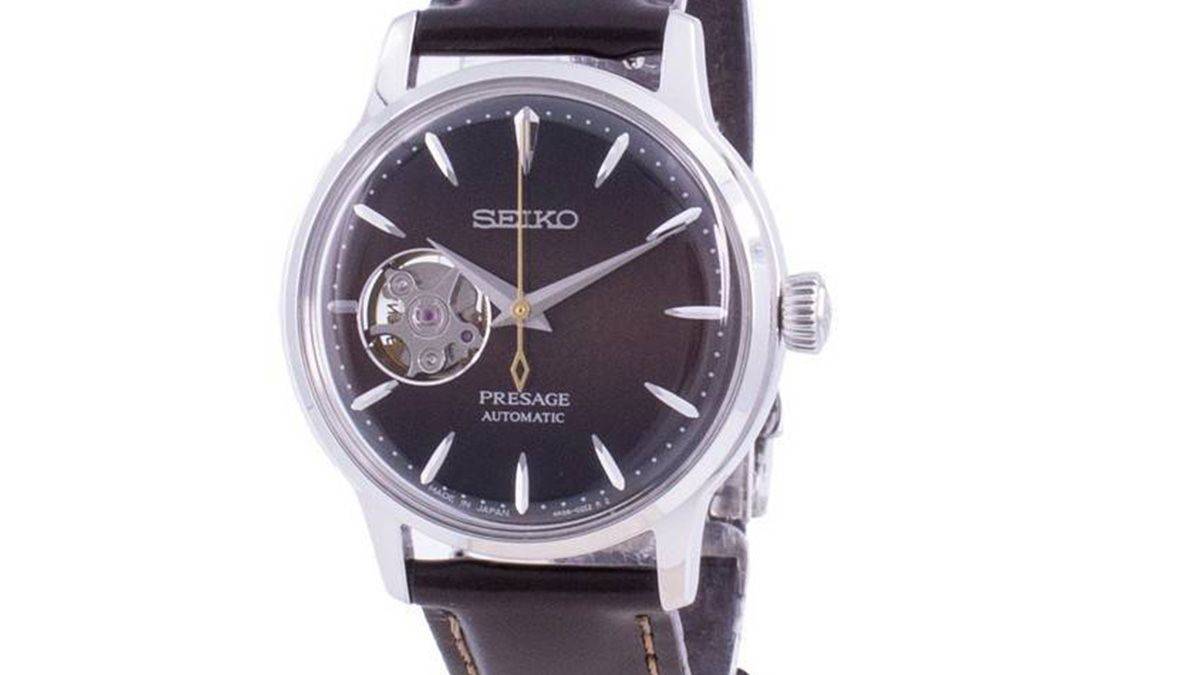

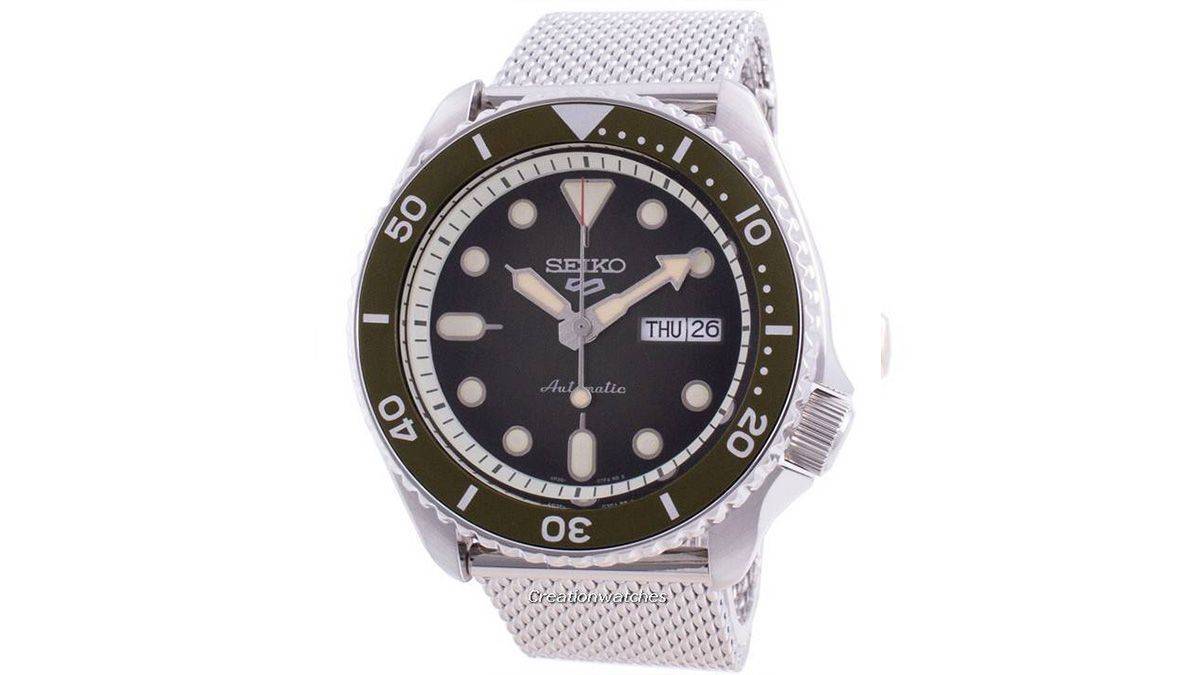

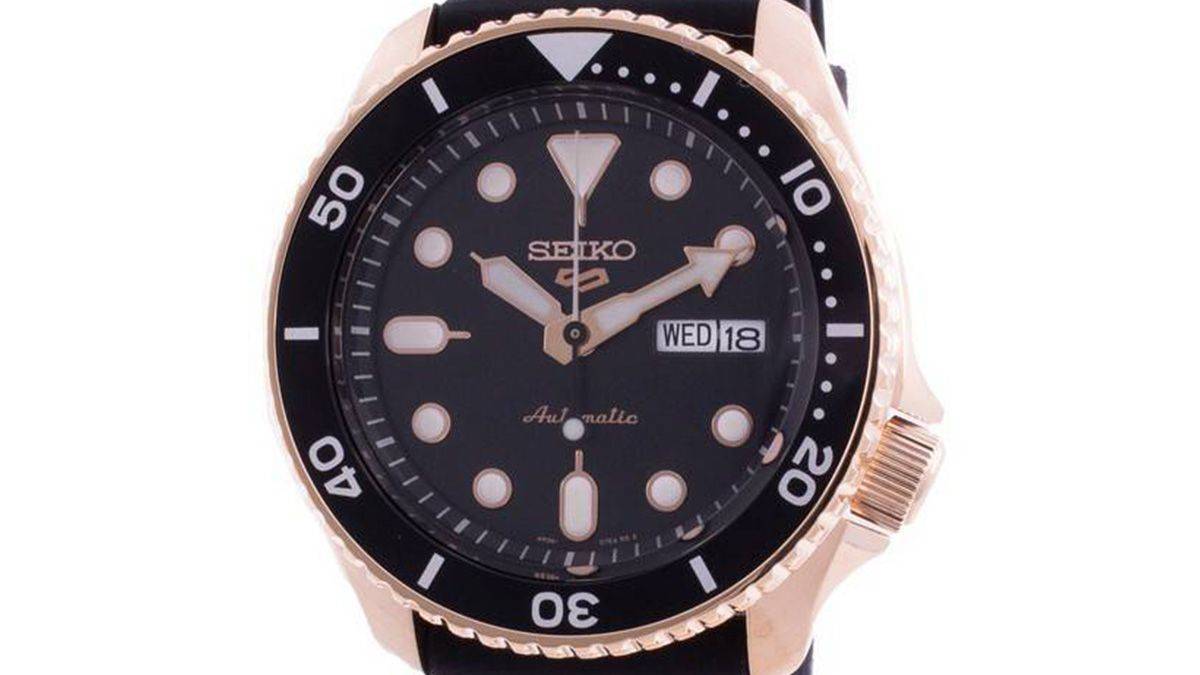

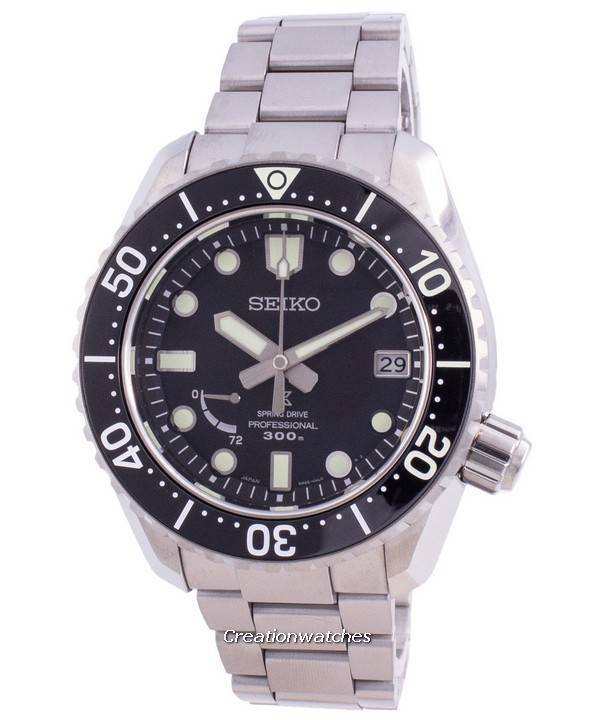

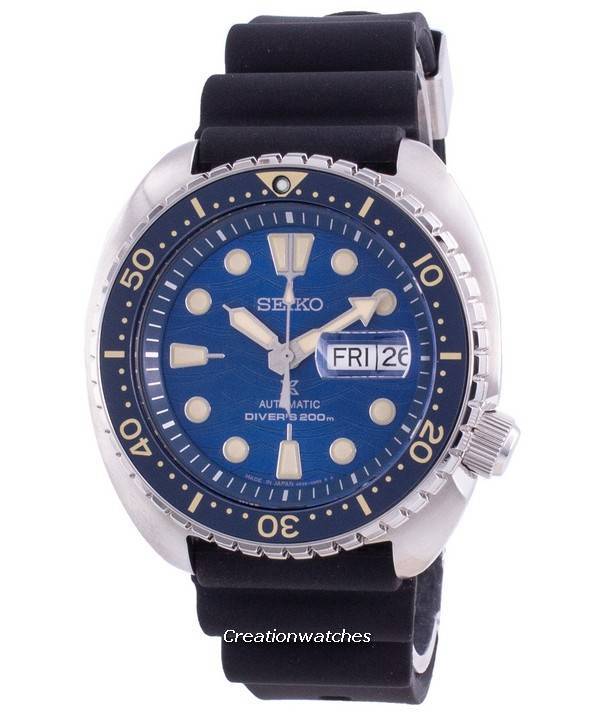

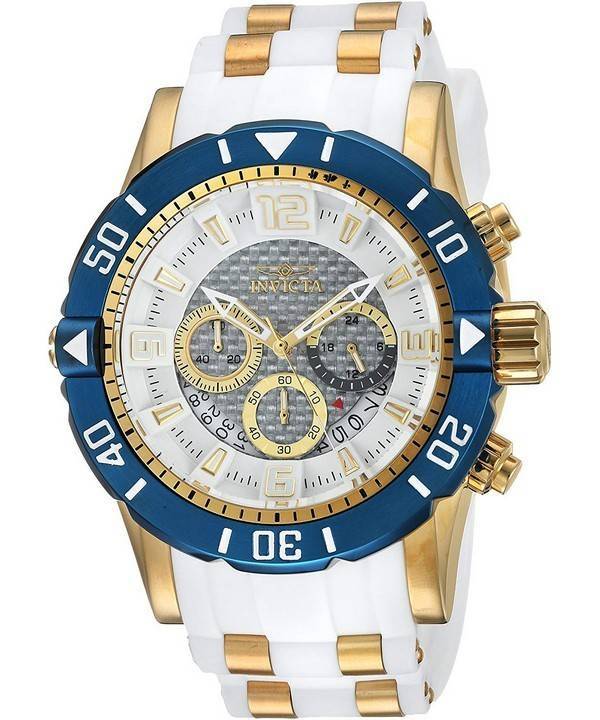

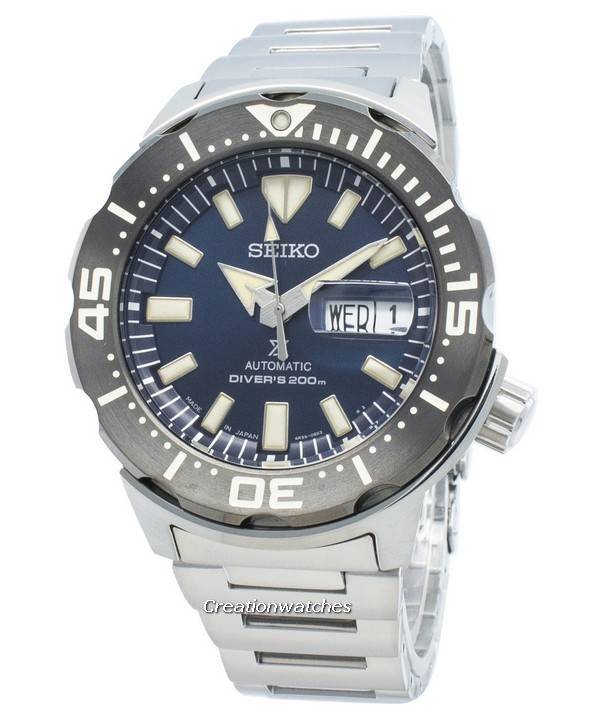

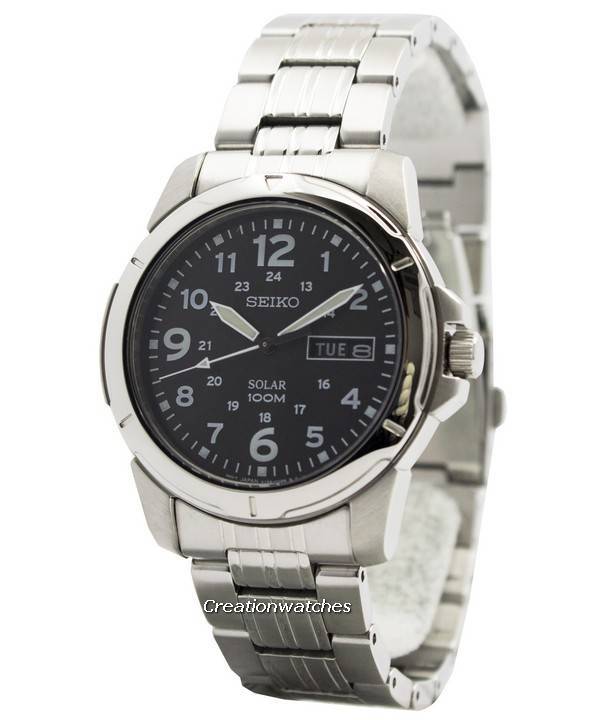

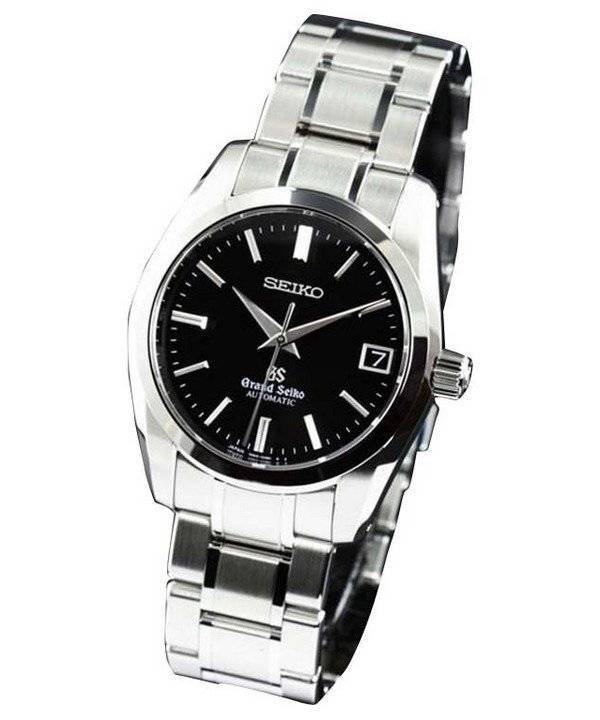

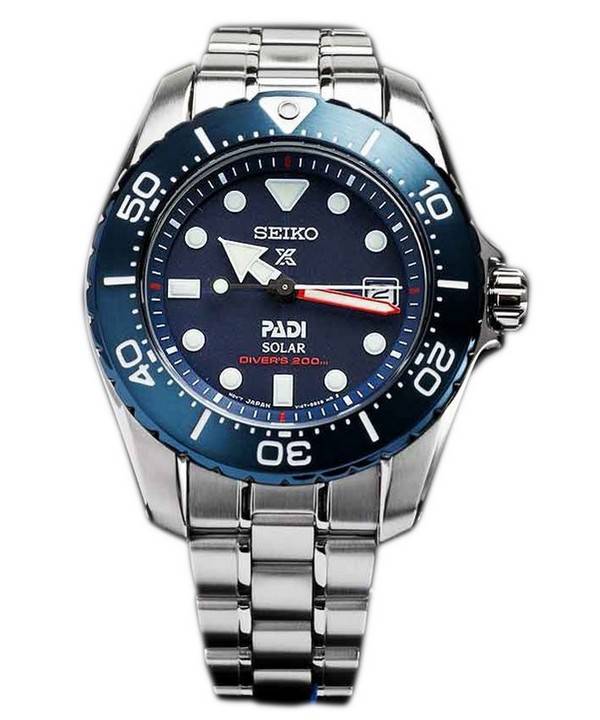

Size adds to weight, but not always. You need to stay careful on the selection of the material. Standard stainless steel (and die-cast metals with or without

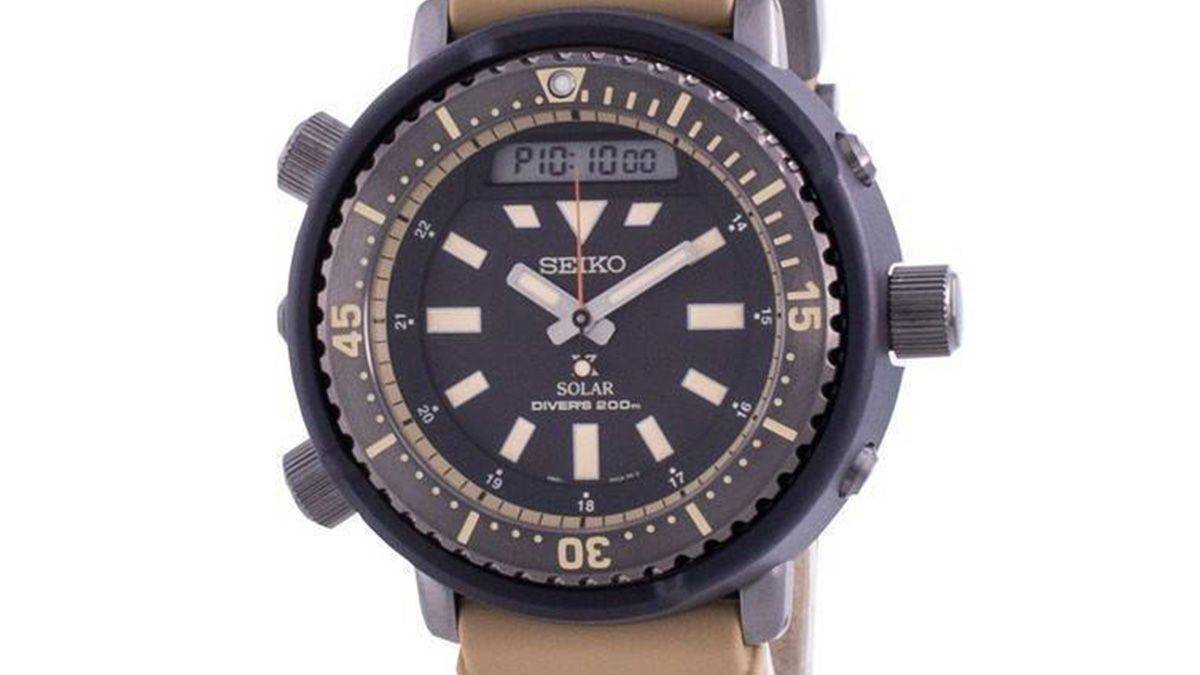

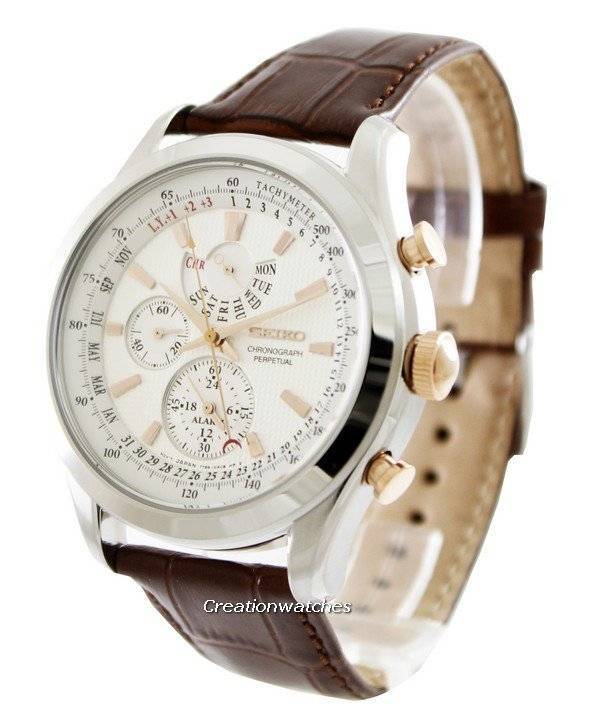

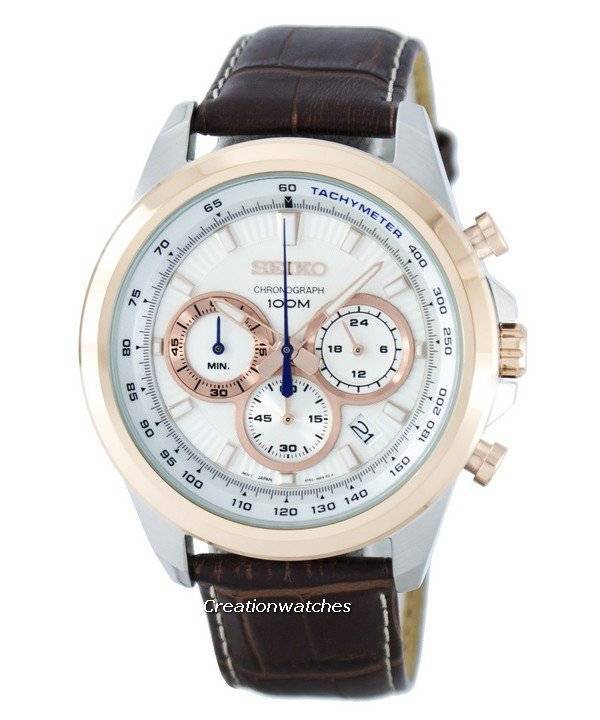

chrome/nickel/gold plating) has this disadvantage. So a Seiko Limited Edition Automatic Divers is often put aside for classic quartzes. They somehow completely overlook Titanium as one of the most practical and affordable choices.

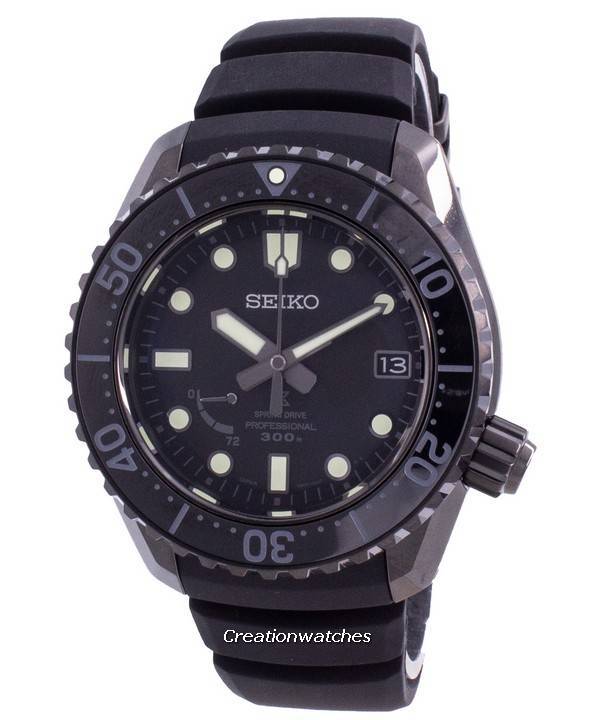

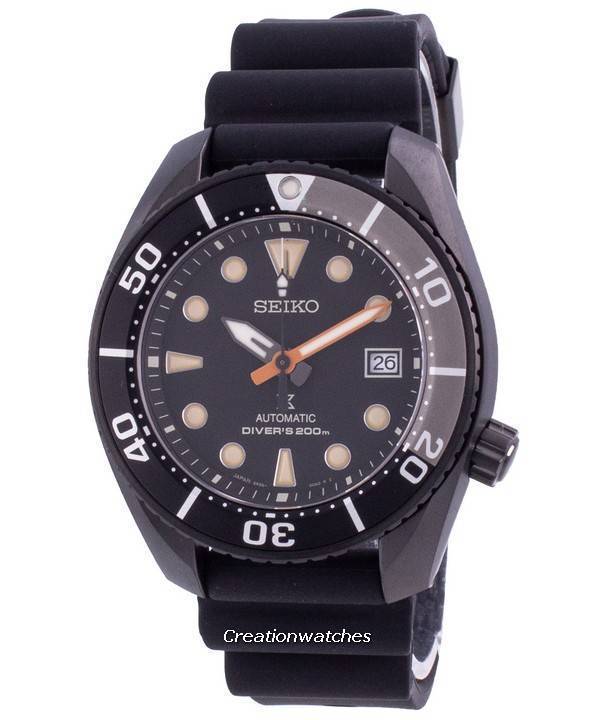

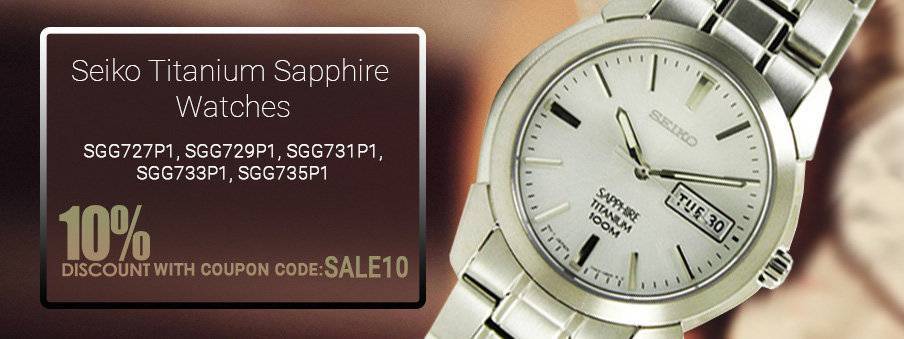

Contrary to general belief, titanium is not a precious metal like gold and platinum and doesn’t always come with insanely high-priced Swiss watches. Practical, to-be-rough-used watches also see widespread usage of the metal; you just need to know which.

Titanium beats steel in many aspects – durability, weight and dent and corrosion resistance, so to honor a time-honored craft as quality watch-making, Titanium fits in just right. It has evolved into the material to create interesting facets without the need to compromise on design and functionality.

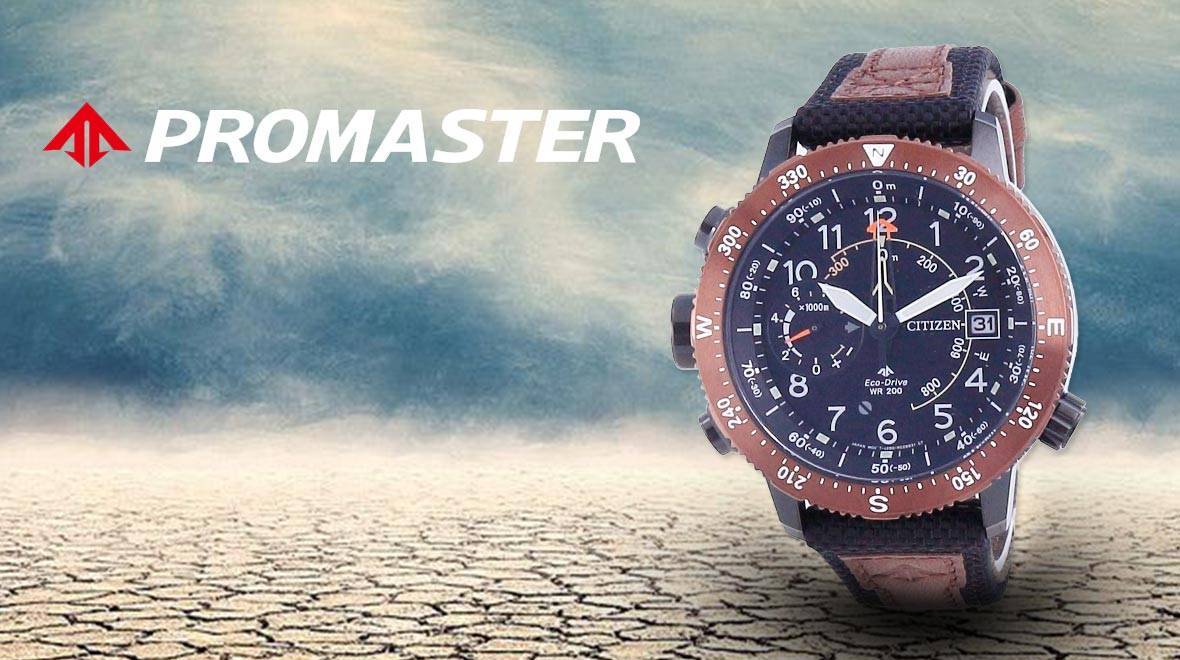

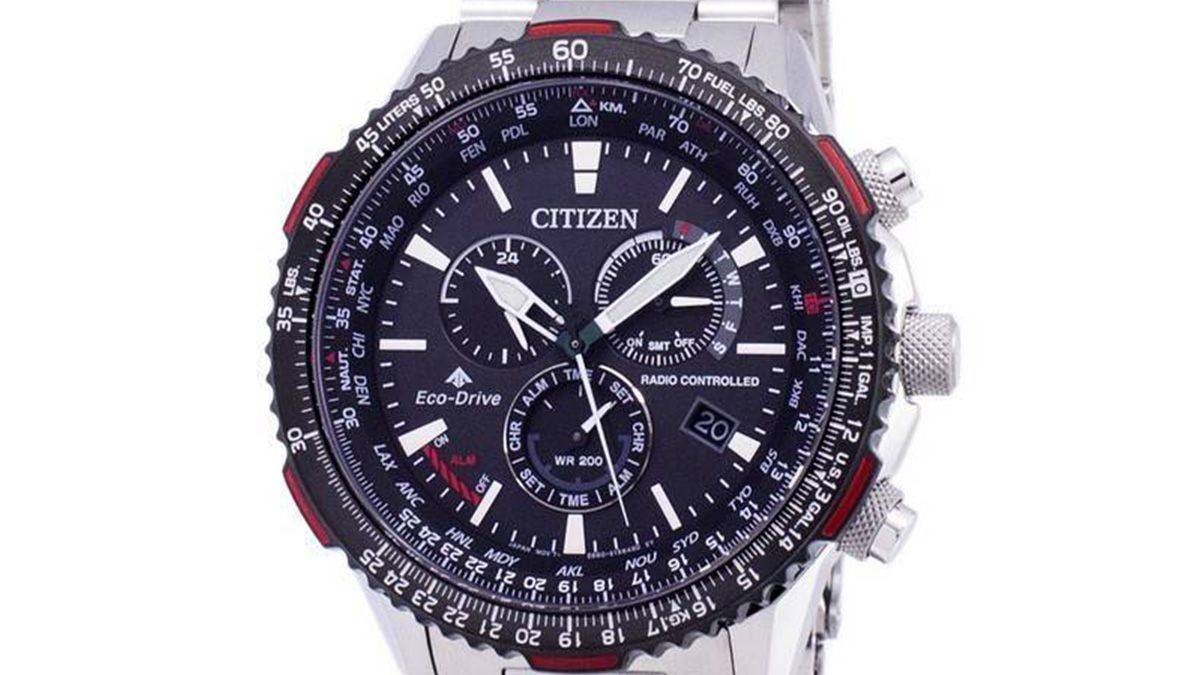

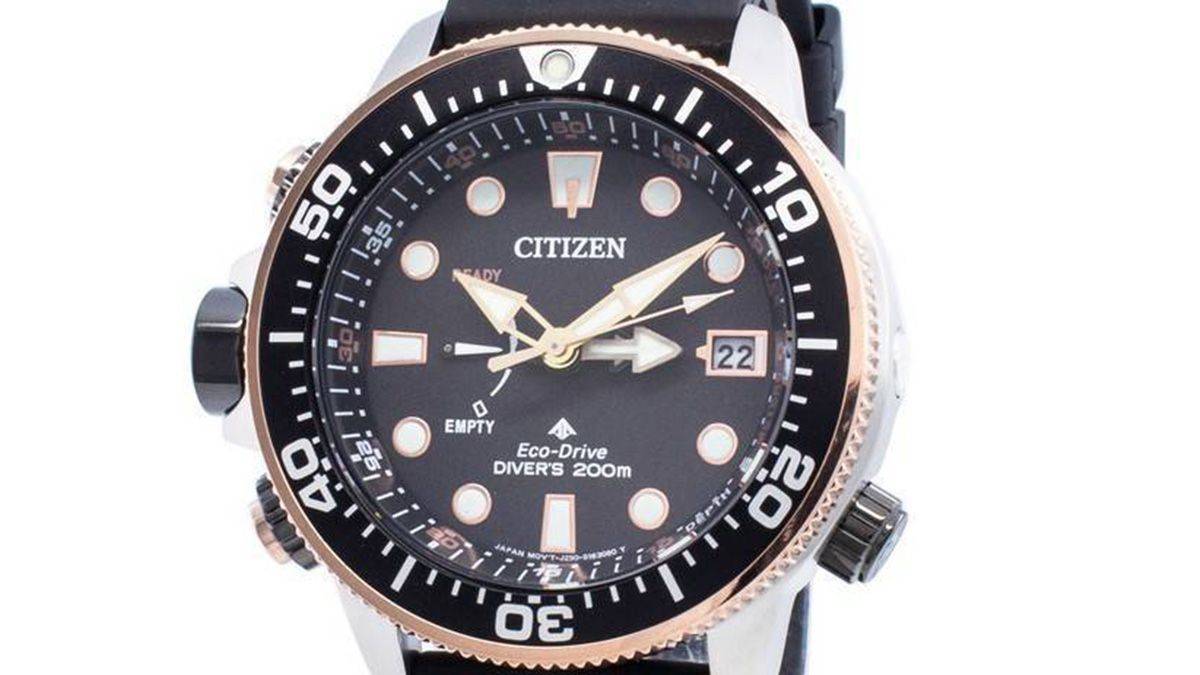

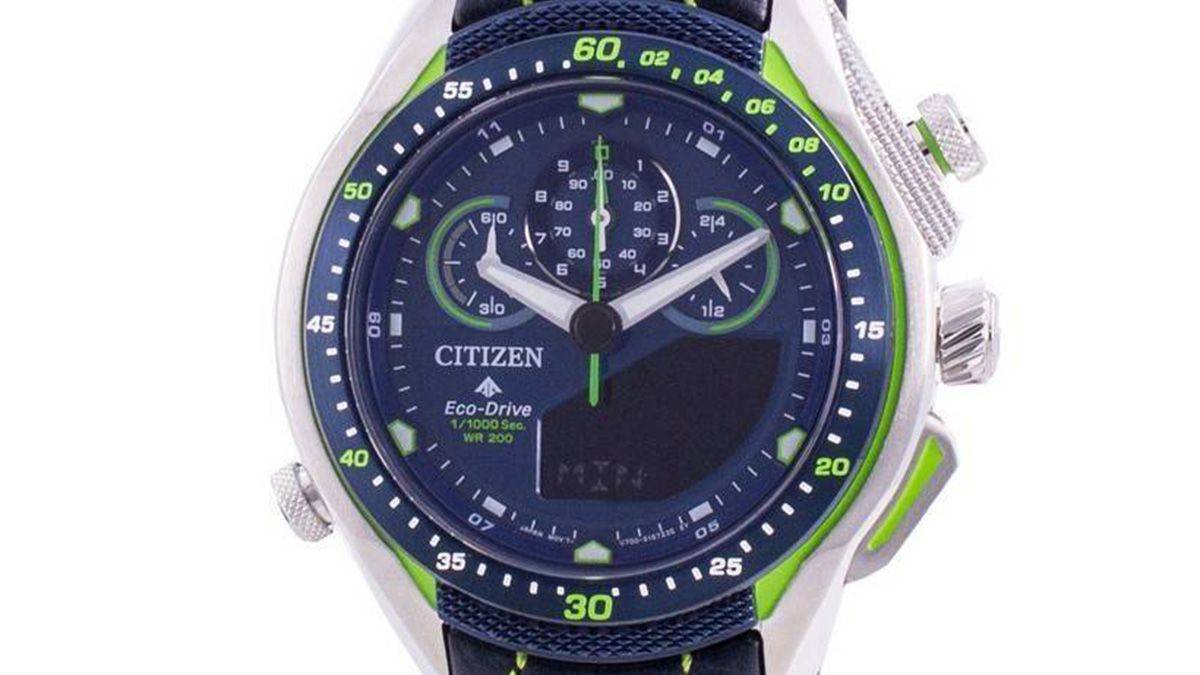

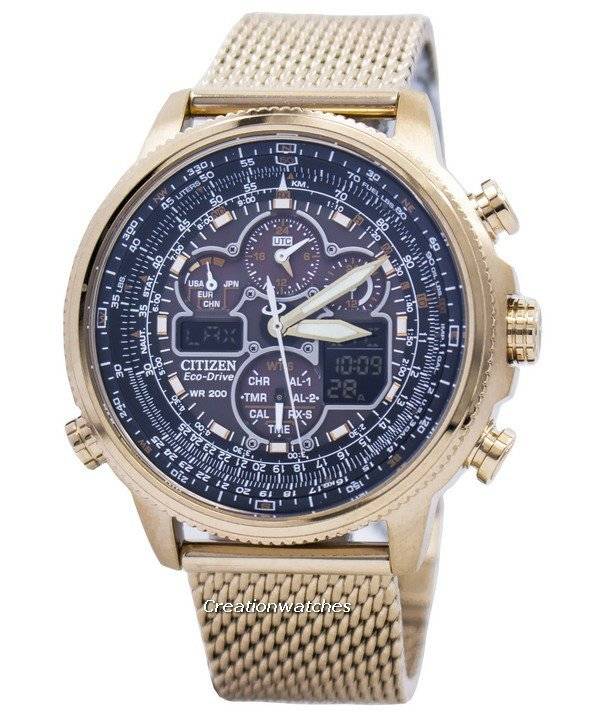

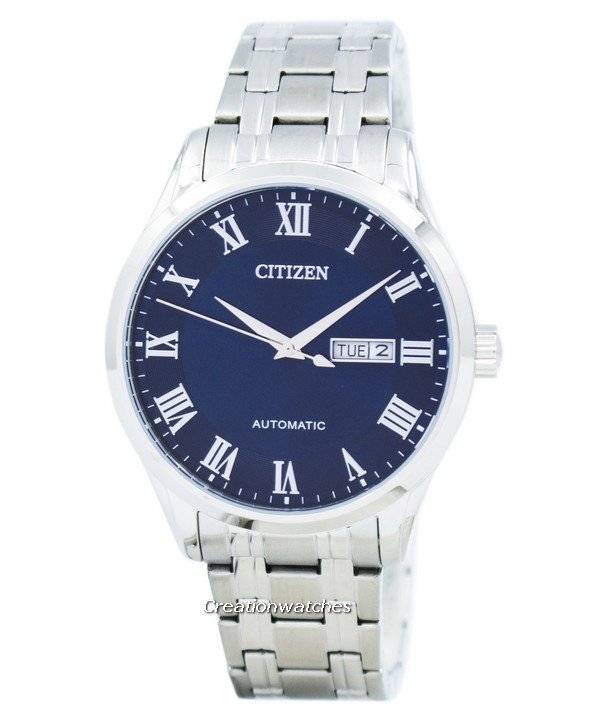

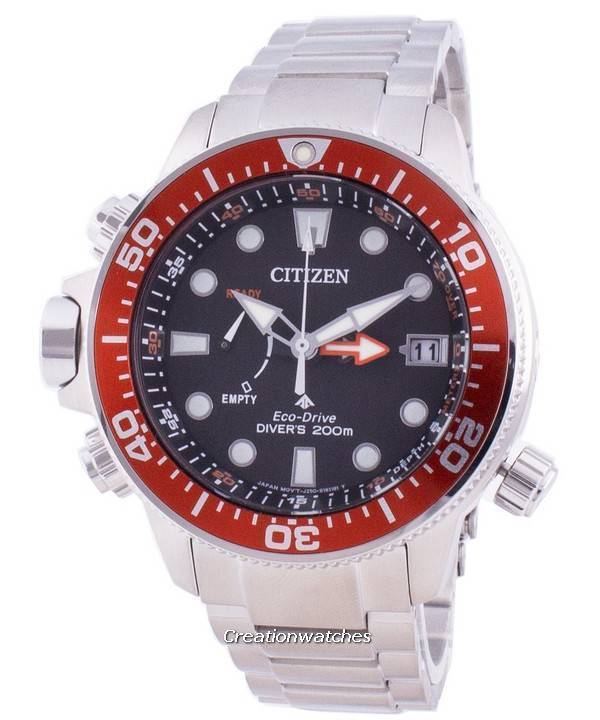

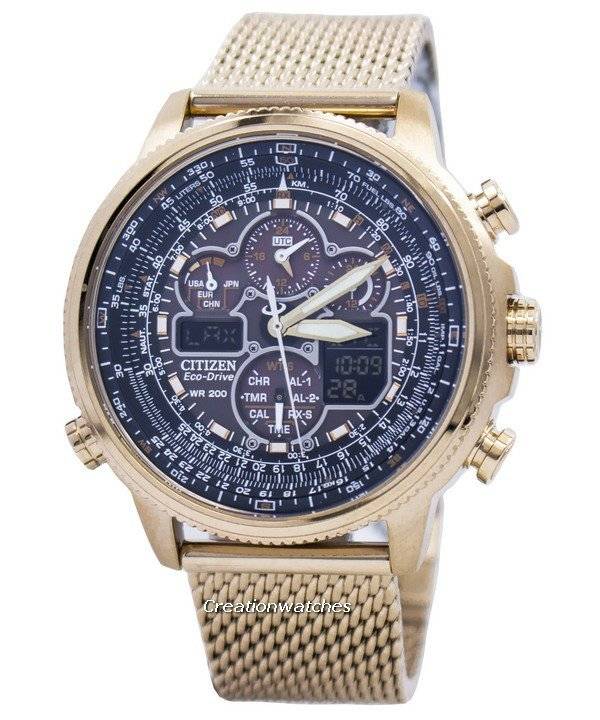

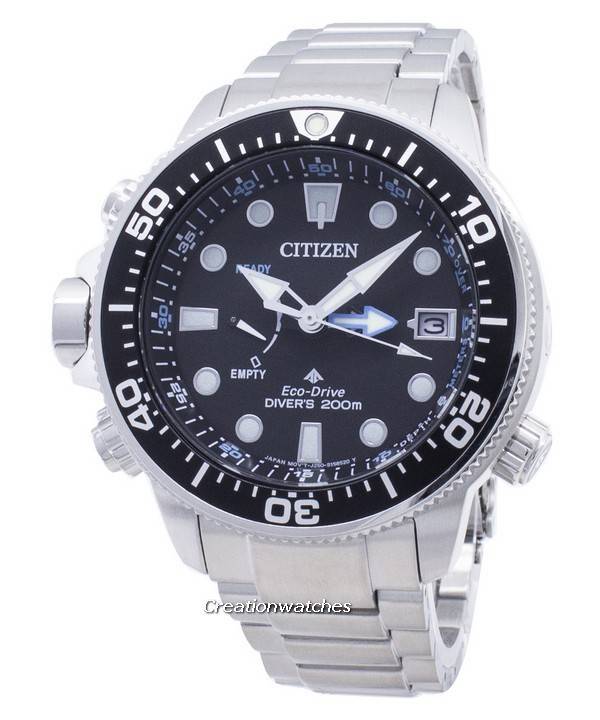

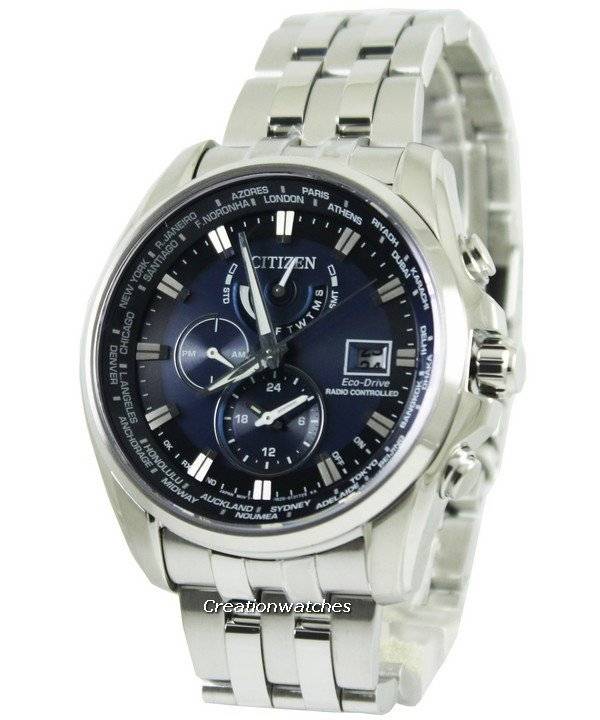

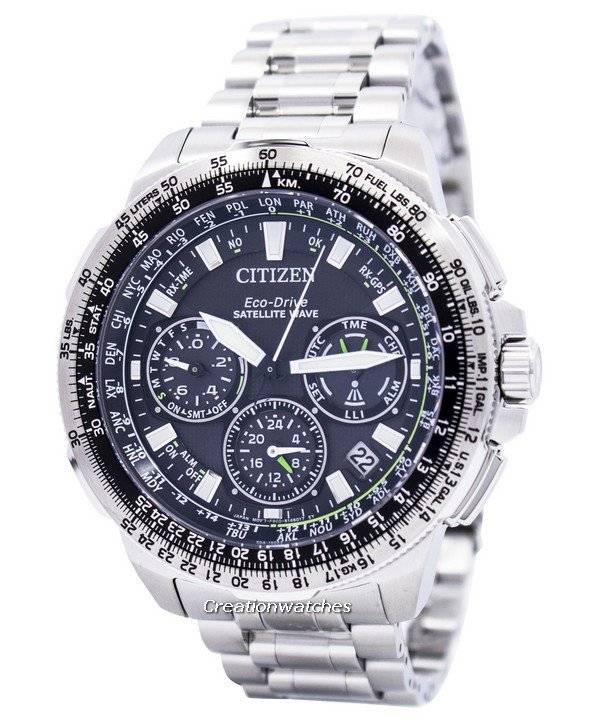

Citizen, however; took titanium to new heights. It’s for over four decades they

have been trying and crossing milestones and making breakthroughs in surface-hardening technology; the latest fruit is Super Titanium (ionized plating method makes it cross 1,200 on the Vickers hardness scale; normal Ti  is only Hv170-200 whereas stainless steel is between Hv150 and 220). It’s 5 times harder and 40% lighter than an equal volume of stainless steel; thanks to Citizen’s proprietary ion-plating method, which heats the metal to over 2,000°C (in vacuum) with concentrated electron beams. This ionizes the titanium. Te ions are then pressure-bonded and apply the surface coating on the titanium case.

is only Hv170-200 whereas stainless steel is between Hv150 and 220). It’s 5 times harder and 40% lighter than an equal volume of stainless steel; thanks to Citizen’s proprietary ion-plating method, which heats the metal to over 2,000°C (in vacuum) with concentrated electron beams. This ionizes the titanium. Te ions are then pressure-bonded and apply the surface coating on the titanium case.

How STi was invented is a rather long story. Citizen had been on a long quest for an ultimate material but technical hurdles had to be overcome. The high tensile strength and an extreme heat resistance needed more than a spearheaded R&D. So titanium fabrication and treatment processes got maximum focus and the end result is STi. The usual transition metal is now even more remarkable for its strength, ductility, inertness to environmental factors and an even lighter weight. Its biocompatibility is its biggest selling point, so worry not on getting some offensive mark around the wrist.