A very short summary:

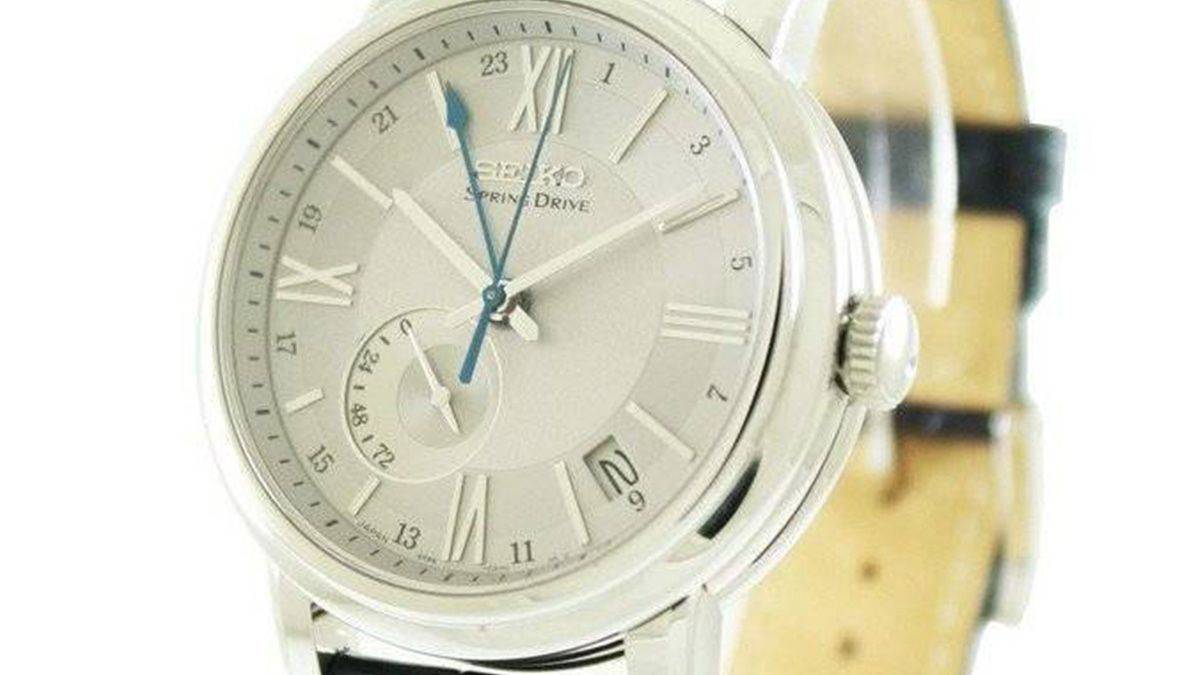

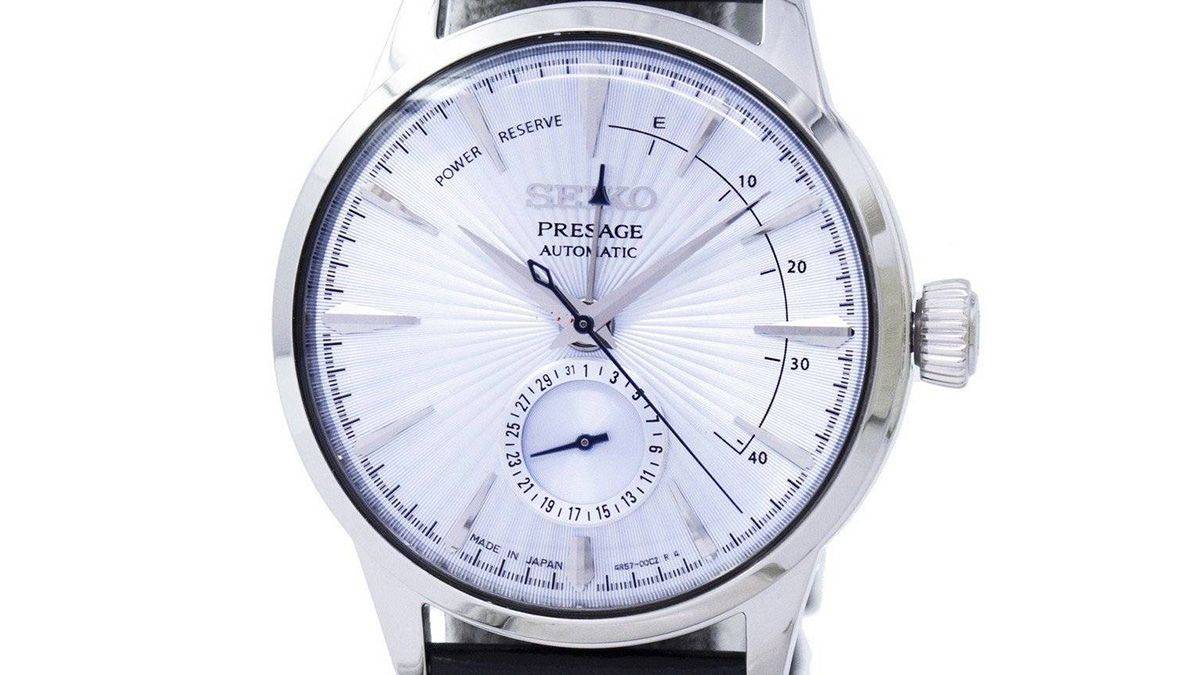

The Spring Drive is different from other quartz-regulated watches and is a unique watch technology by itself. The way it generates energy is like every other luxury mechanical watches; the difference is an electronic regulator for a level of precision never possible for a mechanical watch to attain.

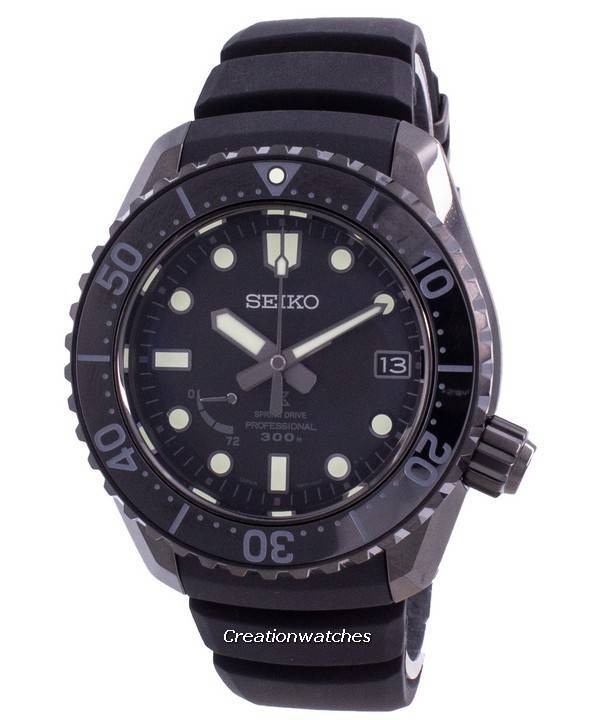

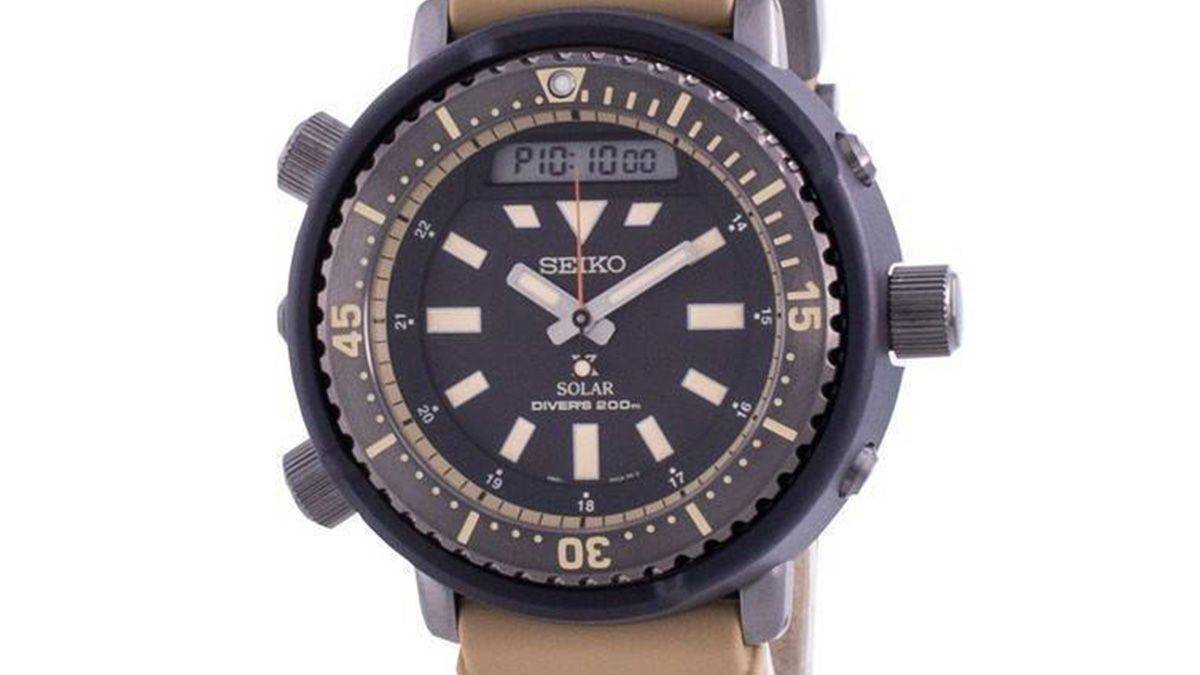

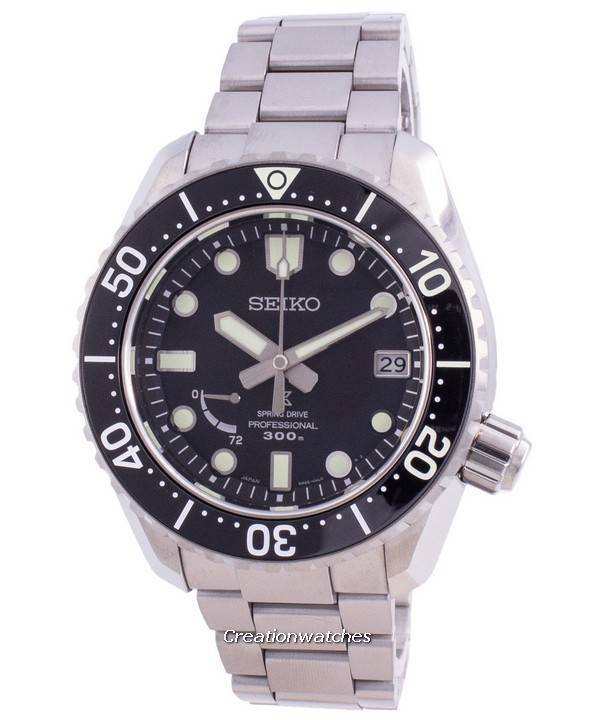

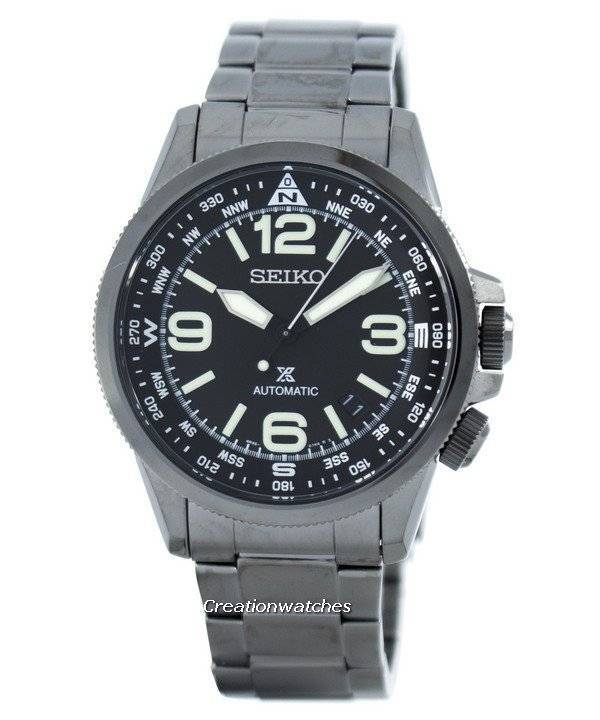

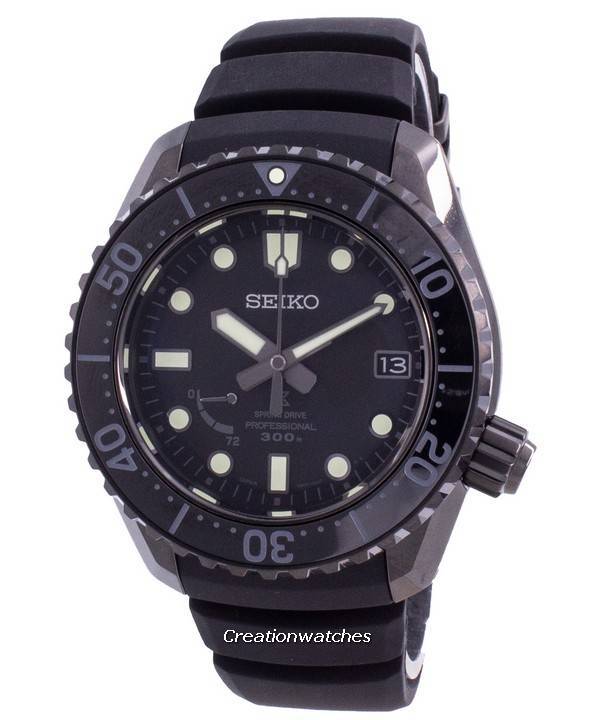

Seiko Prospex LX Spring Drive Professional [Black]

Into the maze: The way things work

- The two, key elements – the power source and time-advancement control – for the Spring Drive are a high-torque mainspring with a high precision IC (integrated circuit). An autonomous way to generate power never allows the watch any downtime, provided you are careful about keeping the mainspring considerably wound all the time; either by winding the mainspring by turning the crown or wearing it normally. Your moving arms will wind it up. Four hours or more every alternate day after winding the mainspring fully is recommended. It will store enough energy reserve with depletions filling up quick; ensuring your watch to never stop abruptly.

- The high level of torque of the mainspring also moves the long, wide hands. They sweep around the dial in smooth glides – signature of the Spring Drive -.with zero stuttering.

- The IC or the Tri-synchro regulator is an exclusive speed control mechanism. In its simplest terms, it is an electronic brake and a quartz crystal; a mechanism to adjust the speed at which the mainspring returns to its unwound state. That is the goal of precise timekeeping. The Tri-synchro regulator, in the Spring Drive fulfills this role; transforming mechanical energy from the mainspring into electrical power (through reference signaling; this is the IC/quartz oscillator’s job) and transforming it into electromagnetic power, where a rotor/stator applies resistance to initiate a braking action. to regulate the motion of the moving parts, thus establishing maximum synchronicity among the parts and the unwinding of the mainspring.

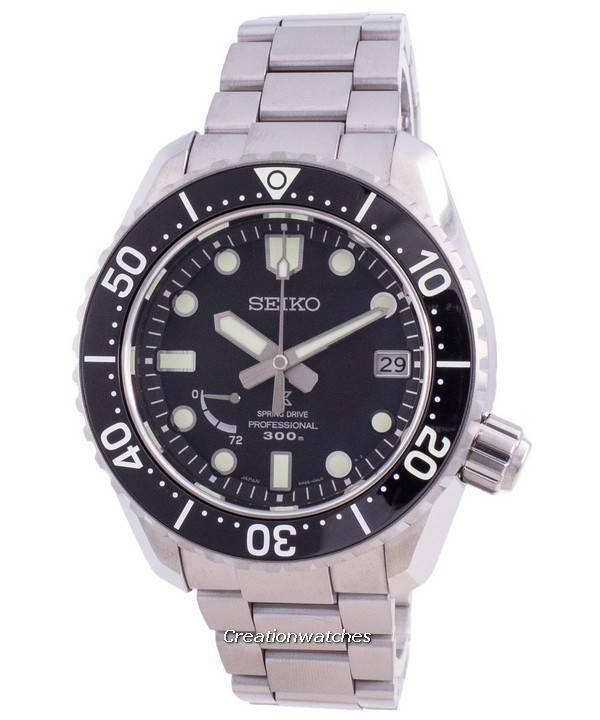

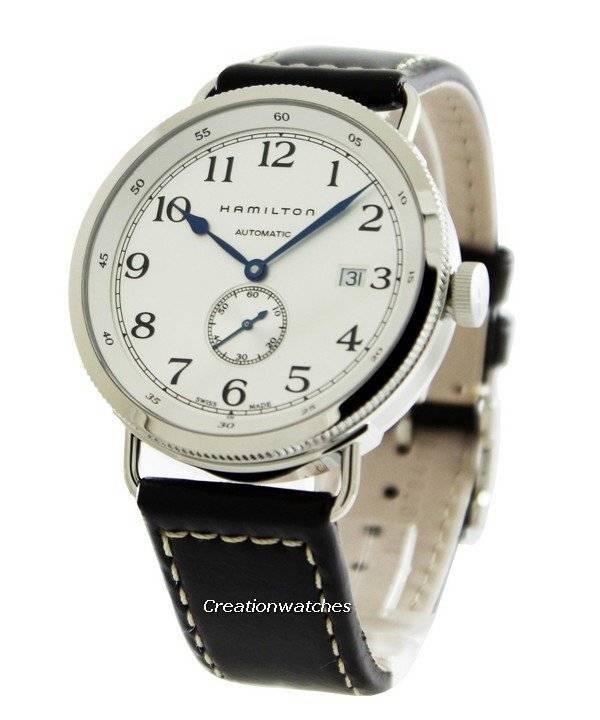

Seiko Prospex LX Spring Drive Professional [Black/Silver]

The science behind the work:

The Spring Drive works the same way as a pedal-powered bicycle’s dynamo. The turning rotor connects to the end of a gear train and rotates around a stator to generate power. This rotor or glide wheel is made to turn eight times fully every second. This generates a slight electric current; an AC voltage (rectified) used for powering the IC with the quartz oscillator in. This eliminates the need for rechargeable batteries/super-capacitors.

The power-surge control is handled by the IC; when the generator runs too fast. The IC short-circuits it and stops it from sending current till velocity is normalized. Think about running; that’s when the mechanism activates. Additionally, it also supplies energy to the resonator and balances gear train speed with resonator frequency, transmitting a precise signal through a quartz-crystal oscillator vibrating @ 32,768 Hz and transmitting precise, reference signals to the IC.

The brake is applied to control speed of the mainspring’s unwinding is when the IC compares the above stated reference signals. A higher ratio between the speed of the rotor and signals intermittently applies a magnetic brake. The gear train senses that to make necessary adjustments, ensuring that precision in timekeeping is maintained.

Maintenance tips:

Best to give it a service once in every 5yrs but pushing to 6 or 7 years also might not be an issue. Be specific about the following when you take it to an authorized Seiko service provider.

- Lubricating oils: There are 80+ lubrication points through which oil should be put with precision. Requires great skill.

- Service and adjustments: Components are set with 1/100thmm tolerances. The extreme precision of Spring Drive can be maintained only at a Seiko authorized facility.

Share your own views about the Spring Drive. Drop a line to gonzo@creationwatches.com