- December 20, 2020

- Watch Gonzo

- 0

Despite frequent misinterpretations to weighty appearances at first sight, some watches, quite contrarily, turn up delightfully light, manageable and maneuverable while on the wrist. All they let you feel is that much just to keep you assured about their presence.

The magic behind lightness

Some think it is lighter gauge steel behind the reduced weight. Or, it is aluminum, which is correct, at times. A lighter gauge than required or an inferior grade of steel – neither are choices for brands with worldwide fame and recognition. All because – aluminum aside – It’s Titanium!

There’s Super Titanium also – in plain words, enhanced Titanium, in all its aspect – but we are not going that way now. You may drop by previous discussions on Super Titanium here and here; today, we look at things that corrode or damage Titanium.

Titanium killers

- Liquid anhydrous ammonia at room temperature: Corrosion rate for titanium is 0.13mm/0.0051 inch/year at 40°C. You can’t handle moist or dry ammonia gas with a Titanium watch on. Ammonium hydroxide or NH4OH solutions (water solution of ammonia) can’t corrode titanium, even if it’s at its boiling point or above; for concentrated solutions of 70% ammonium hydroxide and 30% water. Commercially pure titanium – Grade 1; however, might get ammonium chloride scales formed, leading to under-deposit corrosion. Good news is: You don’t shower everyday in boiling water-ammonia solutions; much less for prolonged spans, so your watch will not suffer. Must you get a watch to withstand even such extreme environments, opt for Palladium containing alloys (ASTM Grades 7, 11, 12, 16 and 17), totally resistant of such conditions. There are a total of 38 grades to titanium; you got to wiki the details.

- Ammonia Steam: Titanium alloys, at temperatures exceeding 150°C or 300°F and in an ammonia-rich environment might turn brittle since ammonia would break into hydrogen and nitrogen and hydrogen absorption causes titanium to embrittle. Ammonia steam corrodes titanium 11mm/year under a surrounding temperature of 220°C or 430°F when the hydride also starts forming.

- Nitrogen and Ammonia: Nitrogen reacts very slowly with titanium; it’s slower than that of oxygen. However, you’ll see surface films forming as surrounding temperature crosses 540°C or 1000°F. The good thing is: your titanium watch will turn into a golden hue and with a substantially enhanced surface hardness improving titanium’s wear performance. This is a technique used to harden titanium further. However, above 800°C or 1400°F, the titanium might break off again for an excessive diffusion of titanium nitride formed previously following the hydride formation process.

What about as a watch material?

Do you really hold a chance to get into one of those environments mentioned above? Guess it’s a no; In that case, the most common forms – Grade 2 and Grade 5 – of titanium are going to last you for a ver-r-r-r-y long time.

Grade 2 is commercially pure titanium with lower strength, heat and corrosion resistance than Grade 5 titanium alloy (Ti 6Al-4V; 6% aluminum, 4% vanadium, 90% titanium). Grade 5 is associated with watches higher in the price bracket while the low– to mid-tier is for Grade 2

The flaw of titanium and the way to mend it

In everyday use, titanium scratches bit easier than stainless steel. This is because titanium forms an oxide layer on the surface naturally, which scratches relatively easy. This, however, doesn’t apply to titanium watches with PVD coating.

Rub it clean after you take it off every time if you want to avoid that touch up with fiberglass pens for a long time. But they make surface scratches disappear easier and better.

BELOW ARE GIVEN LINKS TO SOME OF THE BEST TITANIUM WATCHES. CLICK TO SEE AND BUY THEM:

- https://www.creationwatches.com/products/tissot-247/tissot-t-race-touch-alarm-quartz-t081-420-97-057-04-t0814209705704-mens-watch-11731.html

- https://www.creationwatches.com/products/titanium-230/citizen-super-titanium-bluetooth-eco-drive-bz1045-05e-100m-mens-watch-18618.html

- https://www.creationwatches.com/products/titanium-230/citizen-promaster-radio-controlled-eco-drive-jy8109-85e-200m-mens-watch-18758.html

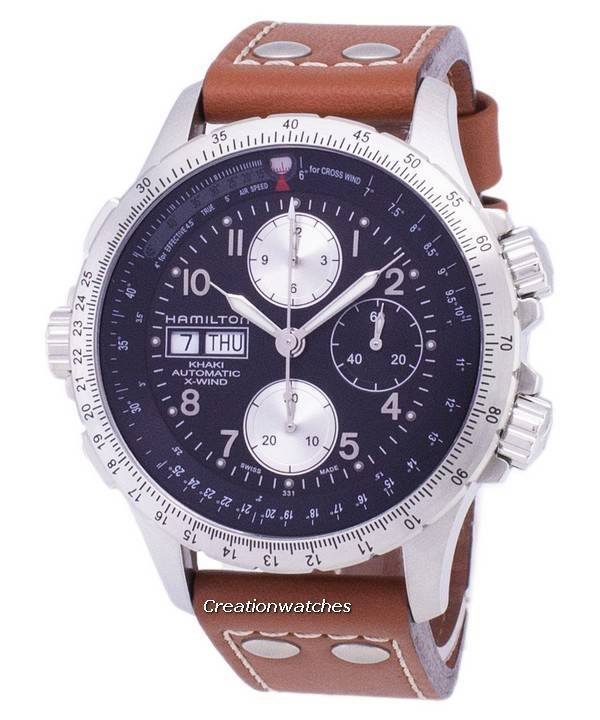

- https://www.creationwatches.com/products/hamilton-watches-250/hamilton-khaki-aviation-titanium-h70575733-mens-watch-3611.html

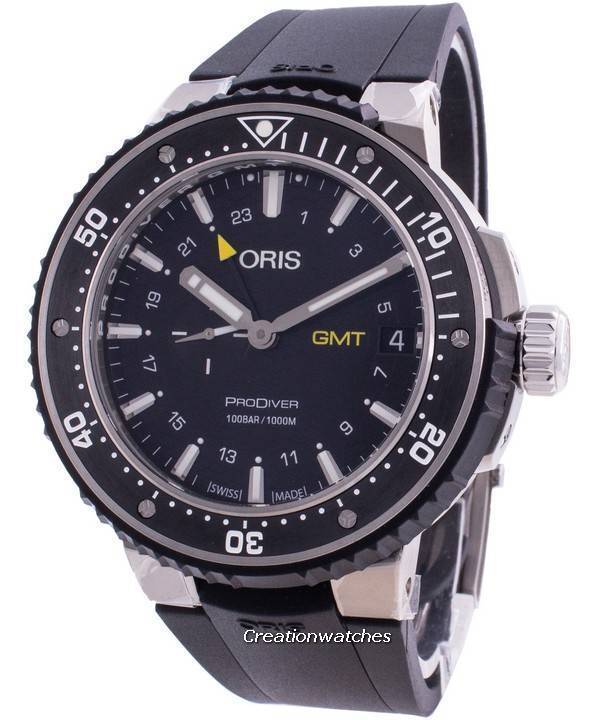

- https://www.creationwatches.com/products/oris-watches-466/oris-pro-diver-01-748-7748-7154-07-4-26-74teb-automatic-1000m-mens-watch-18207.html

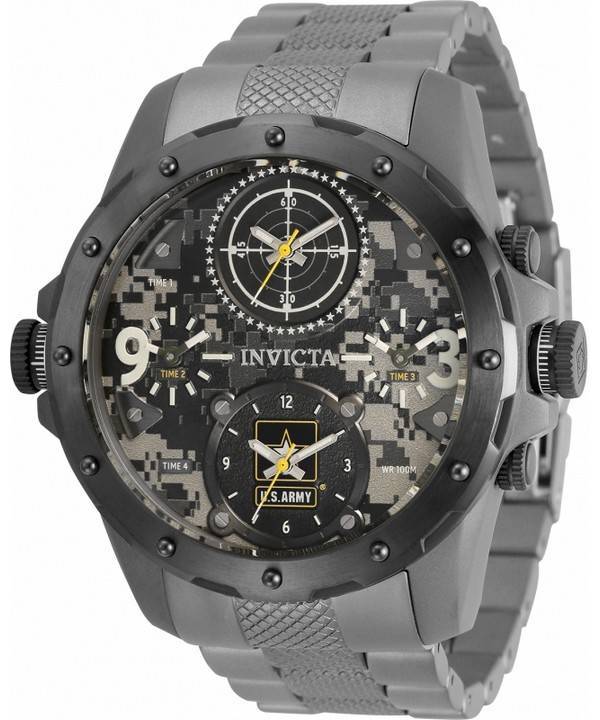

- https://www.creationwatches.com/products/invicta-watches-307/invicta-u-s-army-32059-quartz-chronograph-100m-mens-watch-18446.html

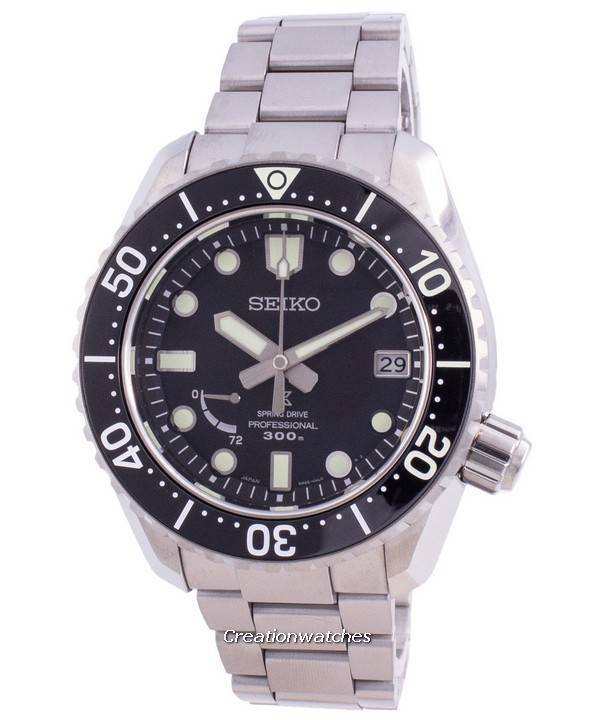

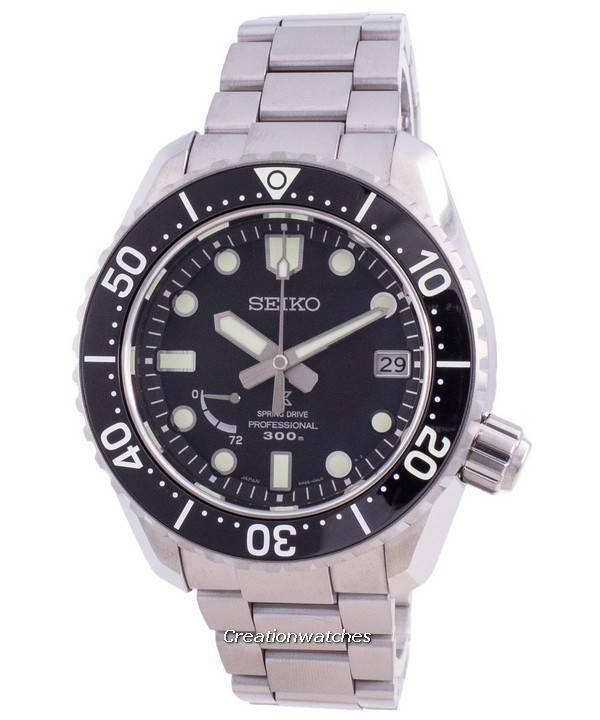

- https://www.creationwatches.com/products/seiko-prospex-299/seiko-prospex-lx-spring-drive-professional-snr029-snr029j1-snr029j-automatic-300m-mens-watch-18464.html

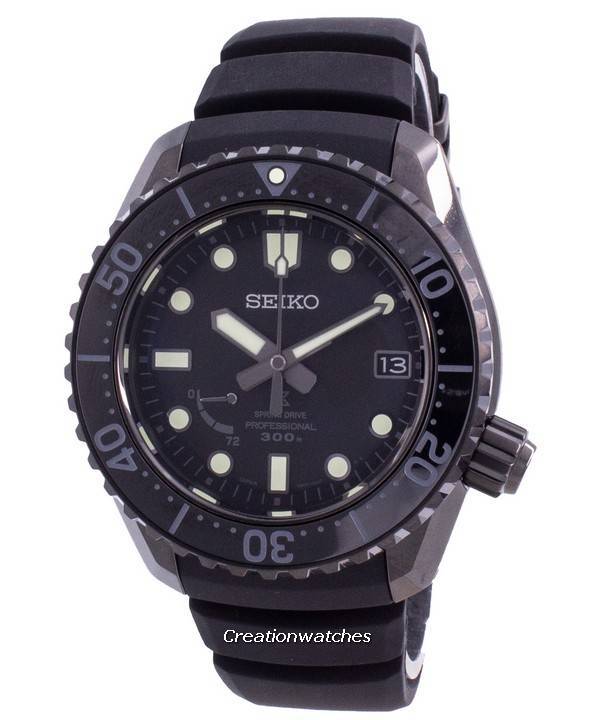

- https://www.creationwatches.com/products/seiko-prospex-299/seiko-prospex-lx-spring-drive-professional-snr031j-snr031j1-snr031j-automatic-300m-mens-watch-18465.html