Titanium definitely puts you a notch above the rest but how many of us are willing to go beyond than what usually meets the eye? True, gold and platinum appeal much more but there’s no denying they lack the tough image of Titanium. Evaluating this material will, thus, need evaluating its properties and while no one is asking you to be a materials engineer, it takes no huge efforts to learn a bit on strength, toughness, hardness and durability and also whether the material’s lightness is a determining factor.

Firstly, it is not pure Titanium in Titanium watches; it is an alloy (there are several of them), the Ti-6Al-4V or the Grade 5 being the most widely used, with strength around 1000 MPa. This is the same T-alloy that goes into aircraft components and some weaponry and also into very high grade watches. There’s also a Grade 2 variety (commercially pure but inferior to Grade 5; around 350 MPa) that makes into mid- to low-grade Titanium watches; this keeps the price lower than that of the precious metals yet gives you the pleasure of wearing something tough and exotic. Despite the inferiority, it excels many of the precious metals in toughness and durability, though the last word is not exactly scientific. An outstanding fatigue life is what applies more.

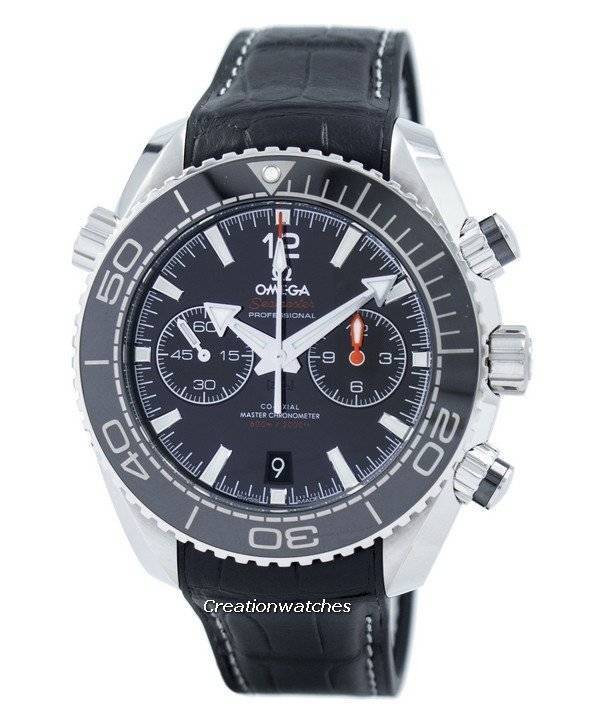

But, why Titanium when Aerospace steel can go up to 2000 MPa? A one-word answer to this is lightness; it is half the weight of same volume of steel. It is the density of Titanium (4.5 g/cc) that outweighs steel (7.8g/cc).

Also, it’s corrosion resistant, as much as platinum and near to zirconium. Titanium doesn’t rust; is imperviable to all but one kind (nitric acid) of acids and is thus hypoallergenic by nature. Titanium forms an oxide layer on its surface, which prevents it from coming in direct touch with the skin.

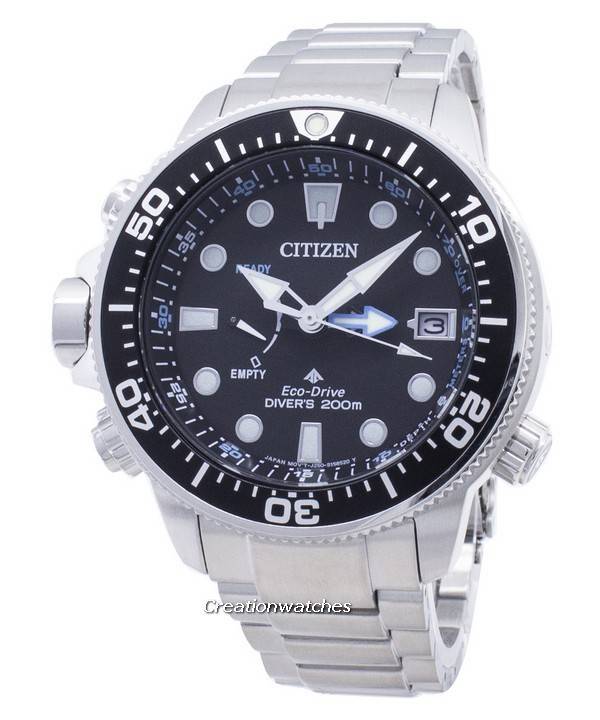

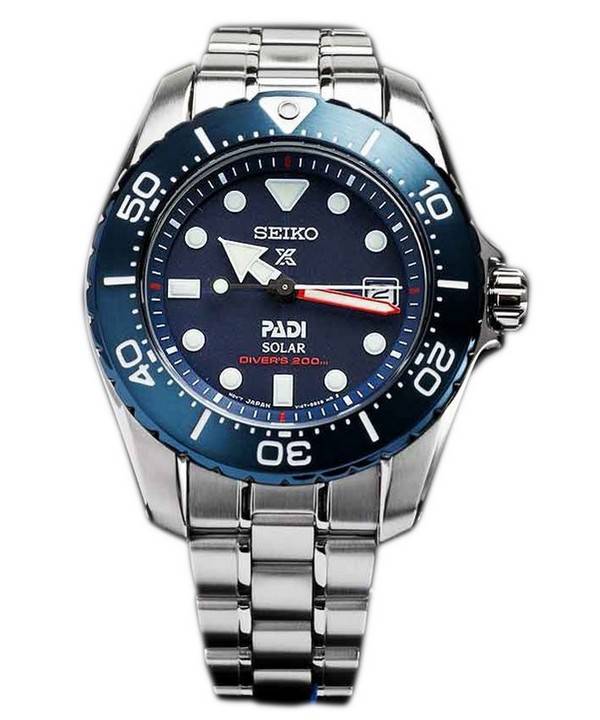

But there are downsides to titanium as well. It has a lower stiffness than steel (which doesn’t make it a good choice for diving watches); also, hardness (it scratches easier than steel; though way much harder than gold or platinum), for which there are coatings applied. To give an estimate, the aforementioned Grade 5 titanium is around 35 Rc in hardness whereas steels reach to anything between 55 Rc and 65 Rc.

So all those hype the price of Titanium watches, right? Not quite, because we haven’t discussed a third factor. Giving titanium a shape is both tricky and tough; welding and forging it and then casting and heat treatments are a colossal task only the cuppa of the aerospace industry formerly. We are lucky since they shared the secrets with the watch industry so we now get to wear the nice titanium cases without mortgaging the soul. But it’s just a matter of time before CFRP (Carbon Fiber Reinforced Polymers) become as popular.

Till then, make sure your chosen titanium watch comes with a good coating. It’s a decision which will keep you happy for many years ahead.

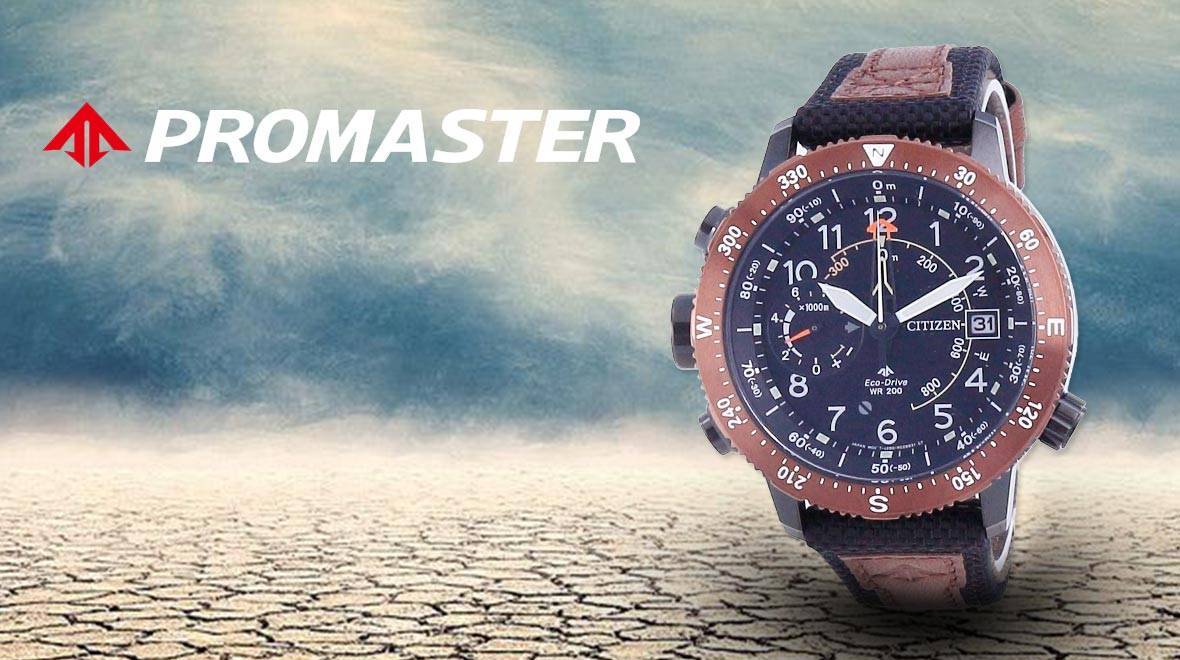

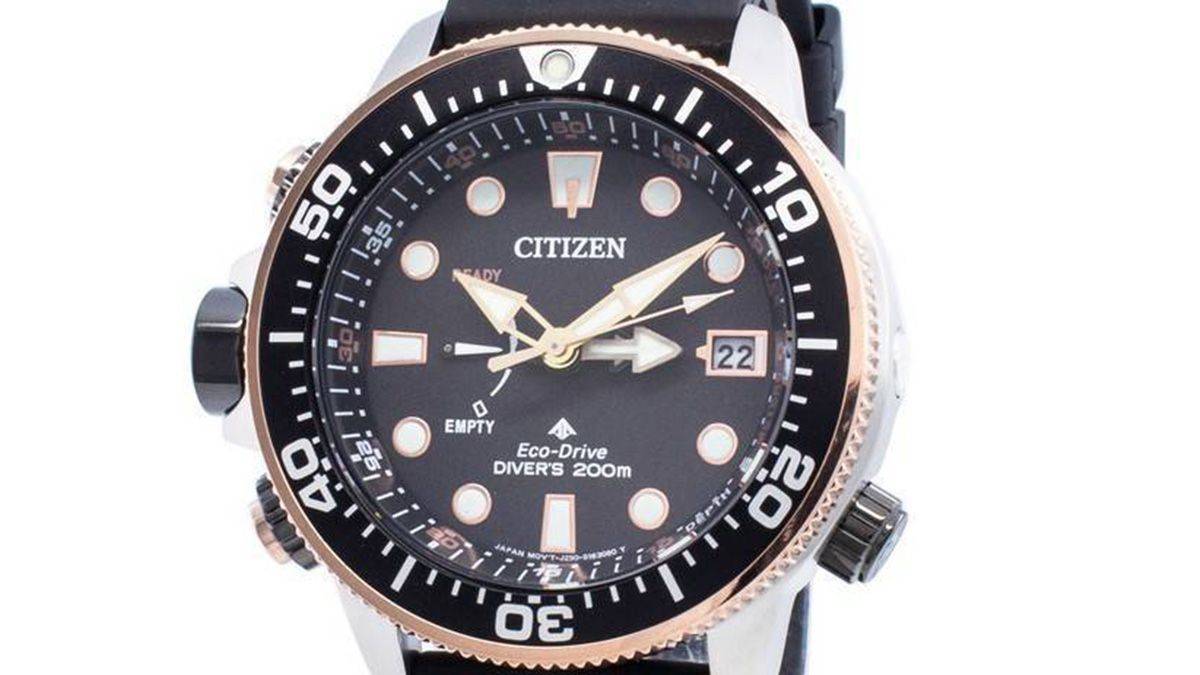

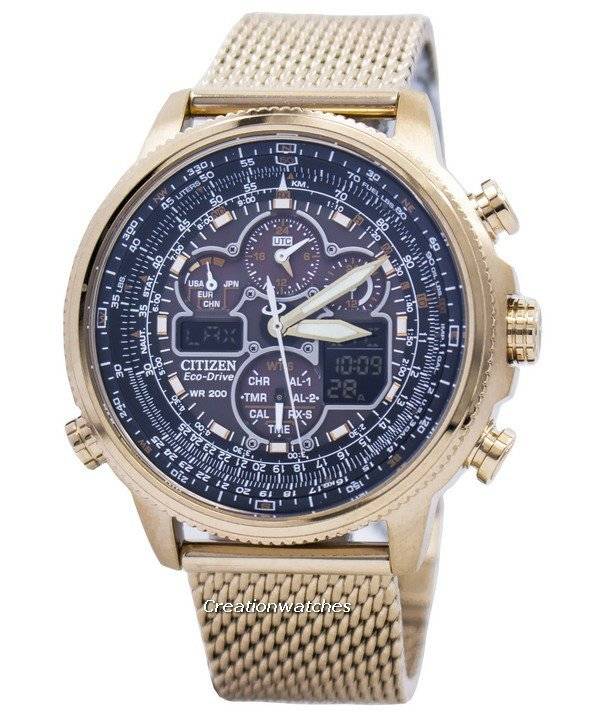

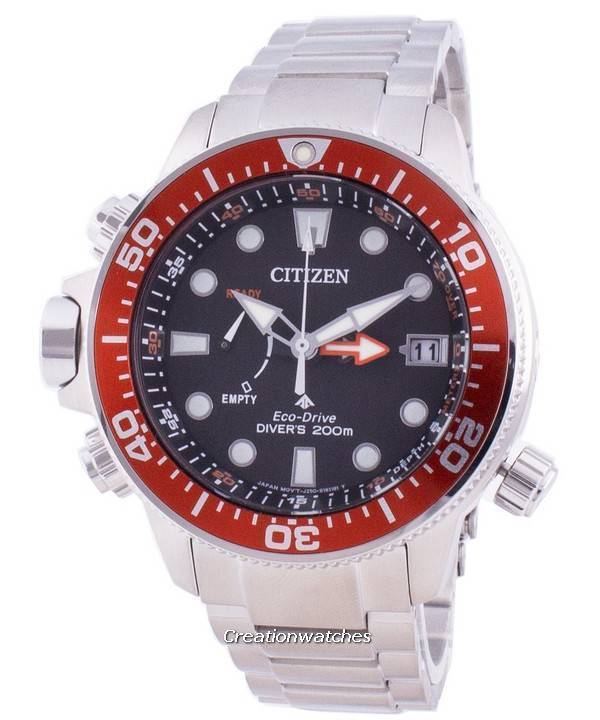

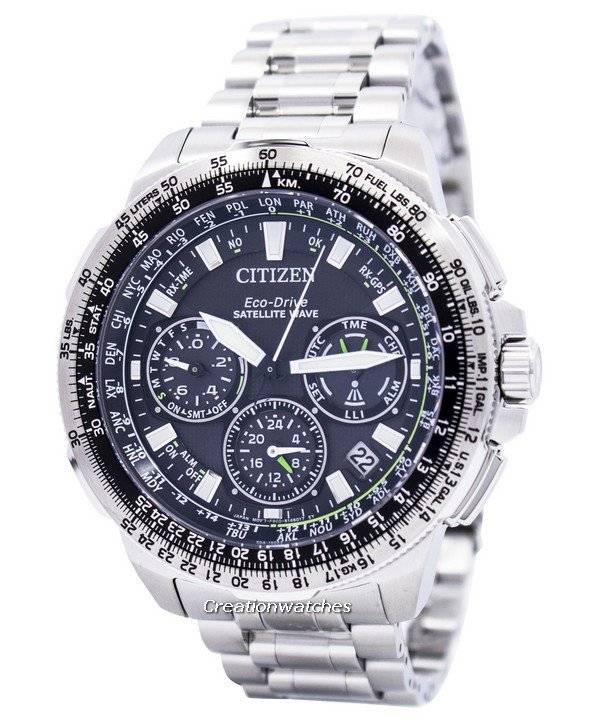

So what about Citizen’s “Super Titanium? Is is really as hard as advertised?