Carbon adds the fizz

There are a few, different types of carbon composites the watch industry uses. Among them, forged carbon composites arrived around the mid-2000; Lamborghini, the sports/luxury auto giant, looking for a cheaper alternative to the composite components they use and Callaway Golf Company together with the University of Washington, found out a different way to produce carbon fiber, which was earlier produced by infusing layers of carbon sheets with resin. The forged composite, instead, uses a sheet of uncured plastic, to which, randomly arranged carbon fiber strands are added. This can further be added to any resin to create a paste that can be shaped in a mould, squeezed into and heated under high pressure.

The first to use forged carbon was Audemars Piguet in 2007, it found place in the Royal Oak Offshore for men; followed by TAG Heuer (the secret behind their signature black colour in the Monaco special edition, the Carrera and Aquaracer are forged carbon cases).

Other composites

- Carbonium®: A completely new generation of material made from aeronautical grade carbon fiber, which is again created from carbon by-products. It was from the French aerospace sector, which composed it out of two-thirds intermediate modulus carbon fiber and one third of high-temperature bearing epoxy. A totally unique aesthetic was the result, which found use in vital structural parts of modern aircrafts. It weighs twice lesser than aluminum; twice as Eco friendly than conventional carbon composites and has more sustainability. The French start-up Lavoisier Composites holds three patents in recycling the base, aerospace-grade carbon material. Carbonium® is aesthetically appealing due to the organic patterns carbon fibers create. Other metals and pigments can easily be added to it. For example, Carbonium® Gold is a thermosetting matrix comprising 7-micron carbon filaments with dispersed gold particles within. First used by Ulysse Nardin (X collection) in 2019.

- CarbotechTM: A carbon fiber composite providing an exceptional technical performance; its uneven, matt black appearance its real charm! It varies according to the way you cut the material. Carbotech plates are machined to give them the required form; these plates are created by compressing thin sheets of carbon fiber under controlled temperatures and high pressure. The end result is a high-end and robust polymer (PEEK or Polyether Ether Ketone), binding the composite and strengthening it further. First used by Panerai.

- Carbon glass: The glass-like carbon is a form of pure carbon. It has an excellent resistance to corrosions, cracks and concussive shocks (100 times stronger than steel), it’s created in highly airtight facilities and floats in water. Aesthetically, it has a smooth and uniform surface (all sides) and accepts addition of colors. Girard-Perregaux introduced carbon glass in 2019.

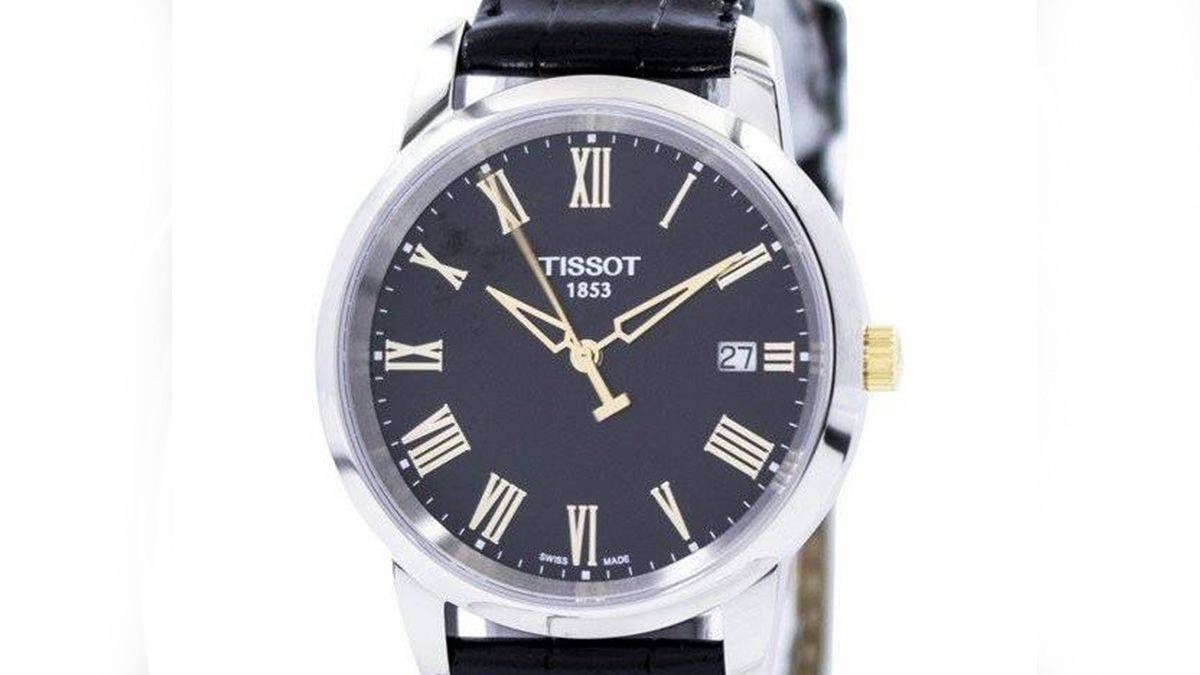

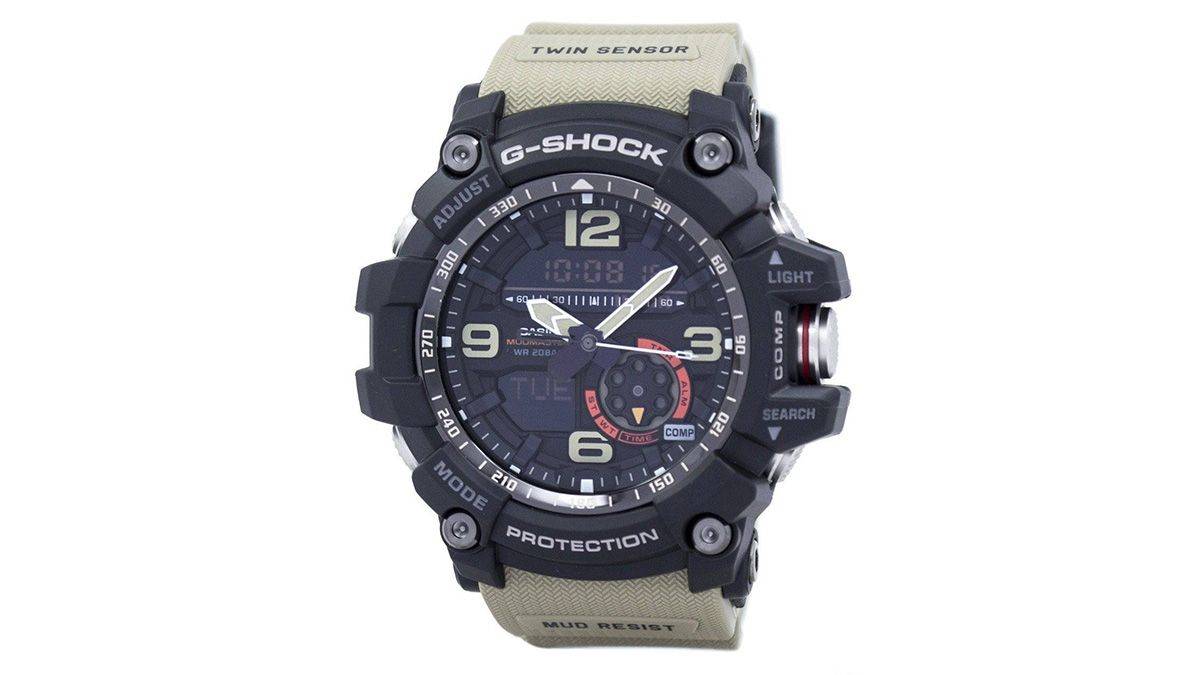

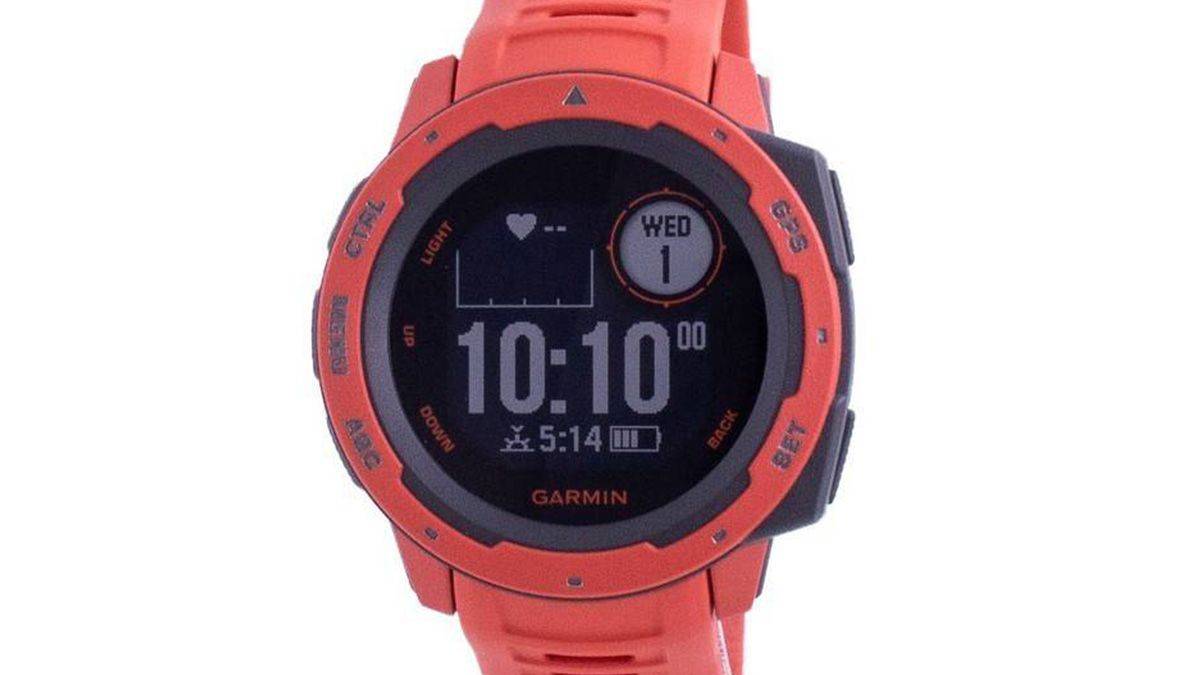

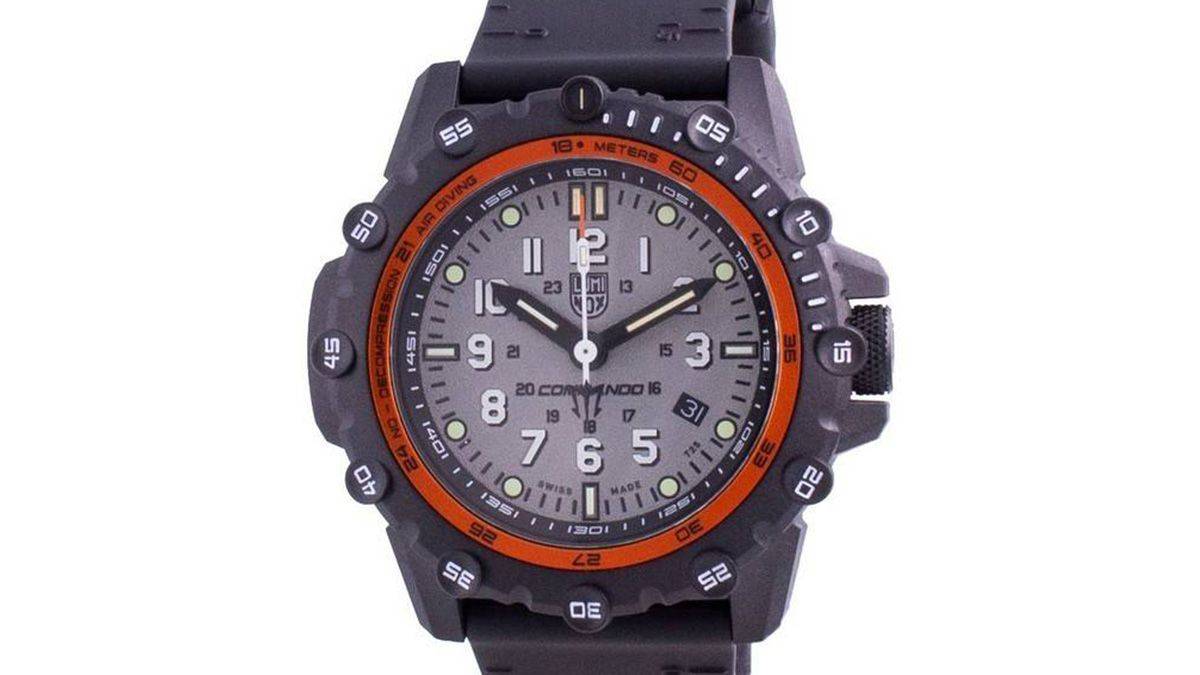

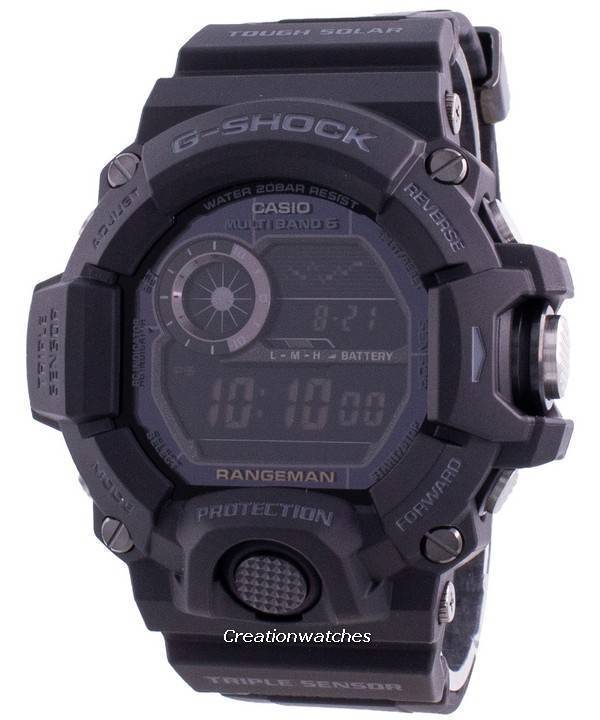

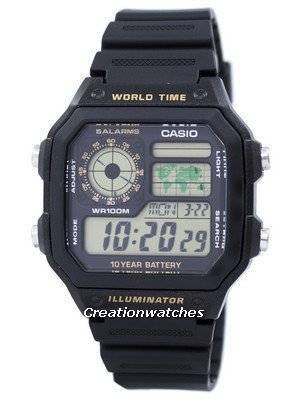

We will continue with the rest of the carbon composites in our next post; for the time being, click the links below to see some of the most affordable watches using resin and carbon as one of their building materials.

- https://www.creationwatches.com/products/diesel-watches-348/diesel-armbar-dz1819-quartz-analog-mens-watch-15439.html

- https://www.creationwatches.com/products/armitron-watches-481/armitron-sport-408253blk-quartz-mens-watch-18159.html

- https://www.creationwatches.com/products/armitron-watches-481/armitron-sport-408284blk-quartz-compass-mens-watch-18160.html

- https://www.creationwatches.com/products/casio-g-shock-atomic-95/casio-gulfmaster-g-shock-atomic-analog-digital-200m-gwn-1000b-1b-gwn1000b-1b-mens-watch-7105.html

- https://www.creationwatches.com/products/casio-sports-205/casio-g-shock-bluetooth-gravitymaster-gr-b100-1a3-neobrite-solar-200m-mens-watch-17499.html