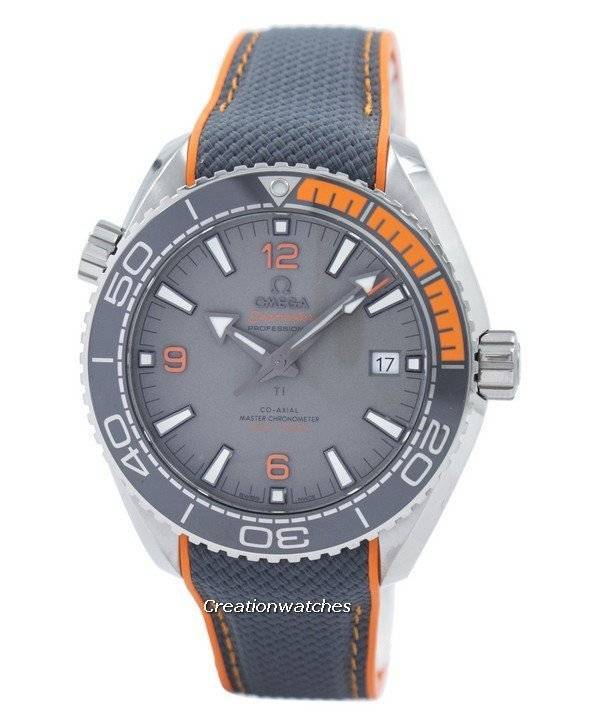

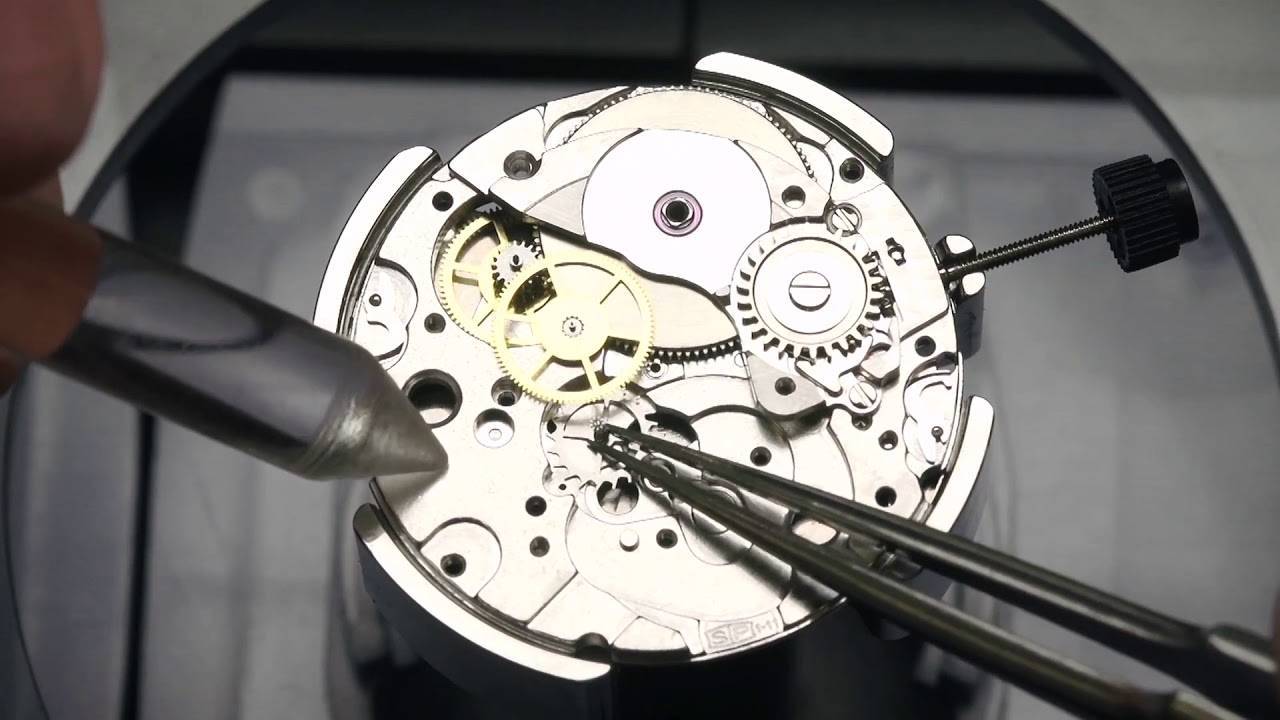

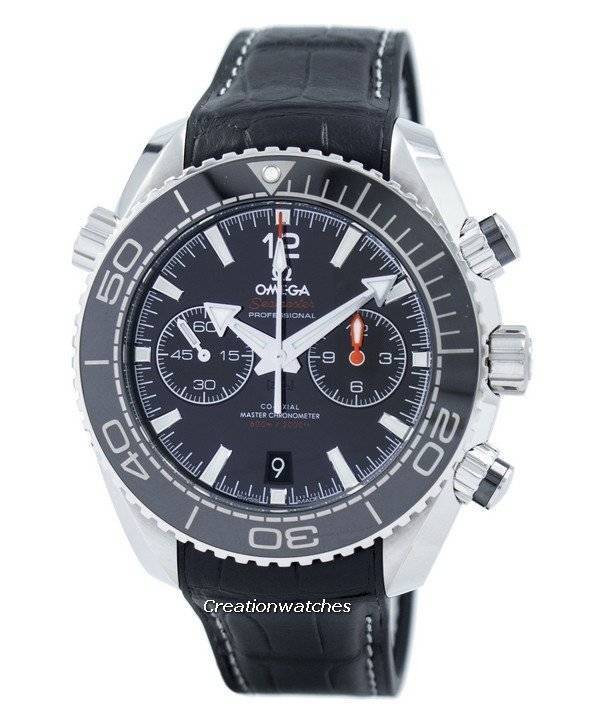

These entire years horology – as a whole – witnessed many different escapements. They came and they went; they still come and go and its discussion is limited within close circles. Even then, the world outside the shrunken range must know of the Co-Axial escapement.

Designed by George Daniels in the 1970s, the British master watchmaker thought about something radically different from the Swiss lever escapement. So much that it creates a cornerstone. The pitfall George Daniels tried correcting was eradicating the need for lubrication.

Note: Certainly, an Omega still needs tiny droplets of oil in its components – say, contact points – but there are looong gaps in between. The ultimate aim is to remove the need for lubrication, take it out of the picture completely.

None was interested in his escapement save Nicolas G. Hayek. His visions led him make several bold decisions and the Co-Axial calibre is now public domain! Still, none tries to copy it. That shows it is not very easy to master. And it’s not coming in any other Swatch models any soon.

Omega says there are three major advantages to the Co-axial. Firstly, it reduces friction within the calibre. Second, this reduces the number of times you need to open and service it to keep the chronometric performance going. Last – It doesn’t depreciate as standard escapement does.

Omega’s visionary ideas turned into industrial reality within a few years. The success of the Co-Axial escapement continues.

A concrete redesigning completely rethought and then adapted to work. It has been ten so far – Co-Axial calibres – 2007 onward. The first Co-Axial movement – 8500/8501 – was used in the De Ville Hour Vision model. The most recent is the 9605/9615. There’s a chronograph, GMT and date functions in that calibre. Contextually: Omega’s 9300/9301 is the first Co-Axial chronograph calibre.

The range of Co-Axial calibres is a constantly expanding one. It’s pretty wide at this point and reflects Omega’s efforts in demonstrating an innovative ability. The backing from Swatch Group brought Omega back to the industry. Today, they offer a full four-year warranty on their Co-axial escapement.

There’s Silicon too in the movement and that’s the non-magnetic balance-spring. They are highly resistant to shear. Meaning, the balance-spring is the mystery behind an improved chronometric performance.

Silicon also wears nominally. It wears much slower than normal metal. It is lighter, too.

Omega makes roundabout 750,000 watches every year. Stephen Urquhart, the CEO says two-thirds or more out of those watches are mechanicals, incorporating Co-Axial technology. In 2012, the COSC (Official Swiss Chronometer Testing Institute) tested and certified 526,046 Omega mechanical movements. were certified by

Omega’s automated assembly line is the ETA assembly line in Granges. It’s completely dust free. This is where the exclusive production of the 9300/9301 occurred. The assembly line is a series of small, automatic, track-run carts holding the movements. They stop at each assembly phase, allowing technicians to work on them. A technician plays his specific part in the assembly procedure each time a cart stops in front of him. The whole work procedure gets recorded on a microchip embedded into the cart, at its every phase. Once been through all the workstations, it moves on to the testing station. Once Okayed, they are sent for the COSC labs for the certification.

We look forward to find all Co-Axial calibers in their non-magnetic form soon. Also, a certification that’s beyond COSC and that’ll keep the gold oscillating-weights and balance-cocks intact!

Wish you all a Happy New Year.

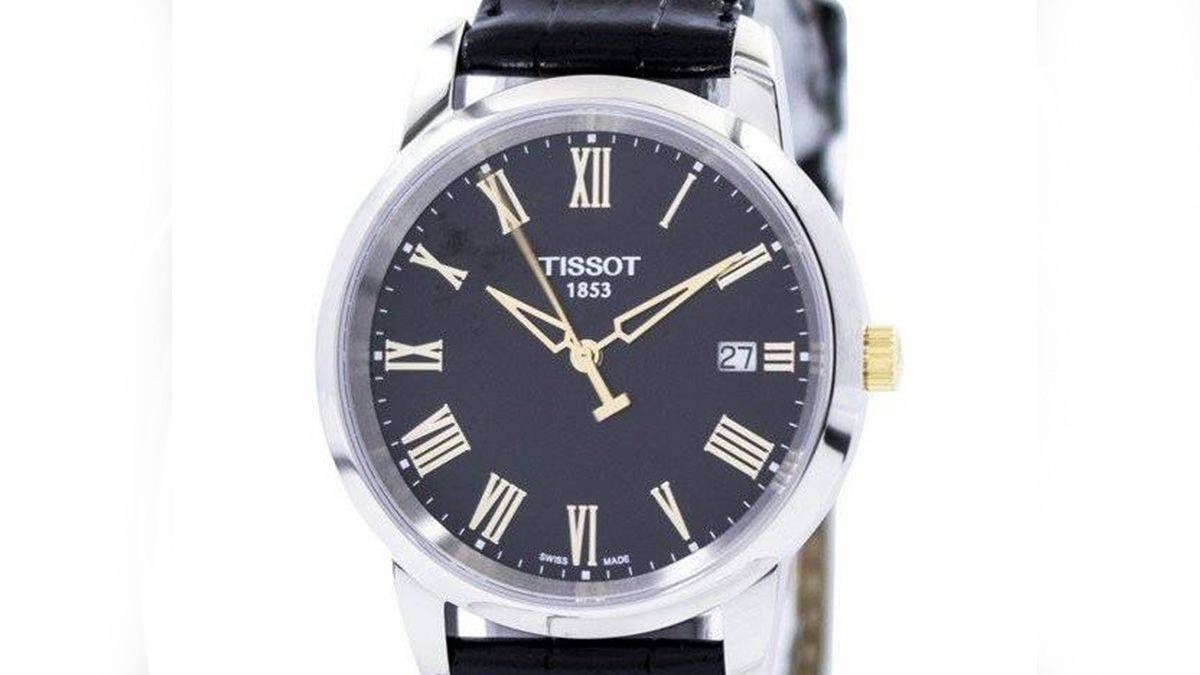

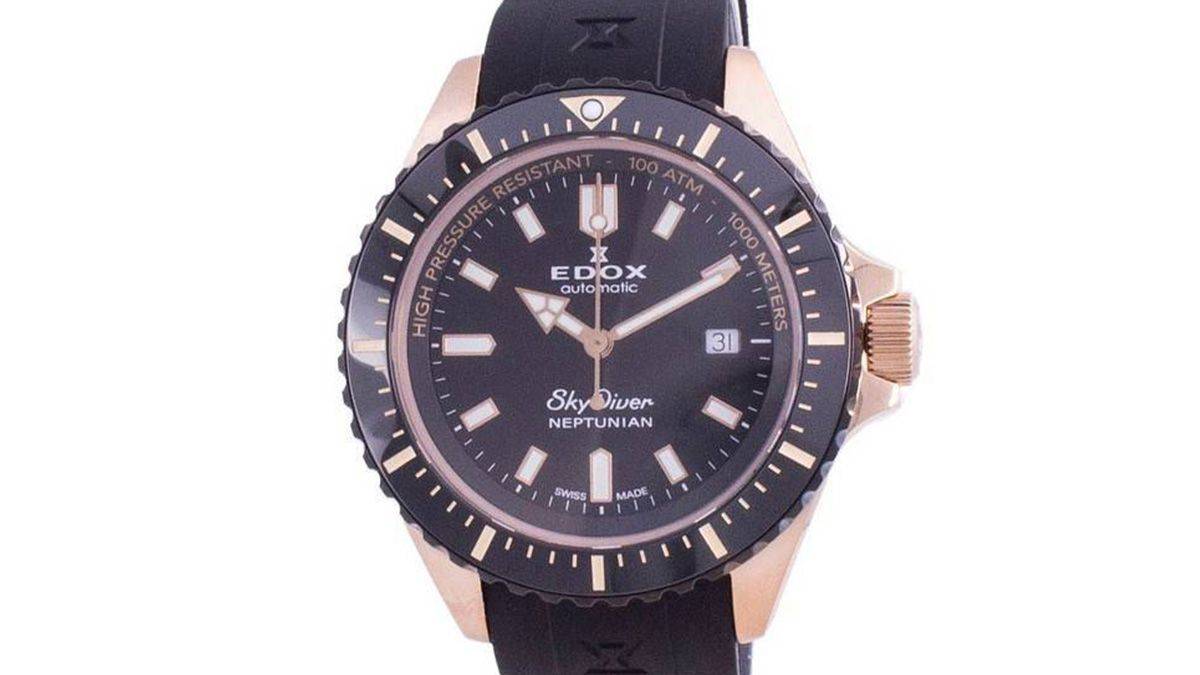

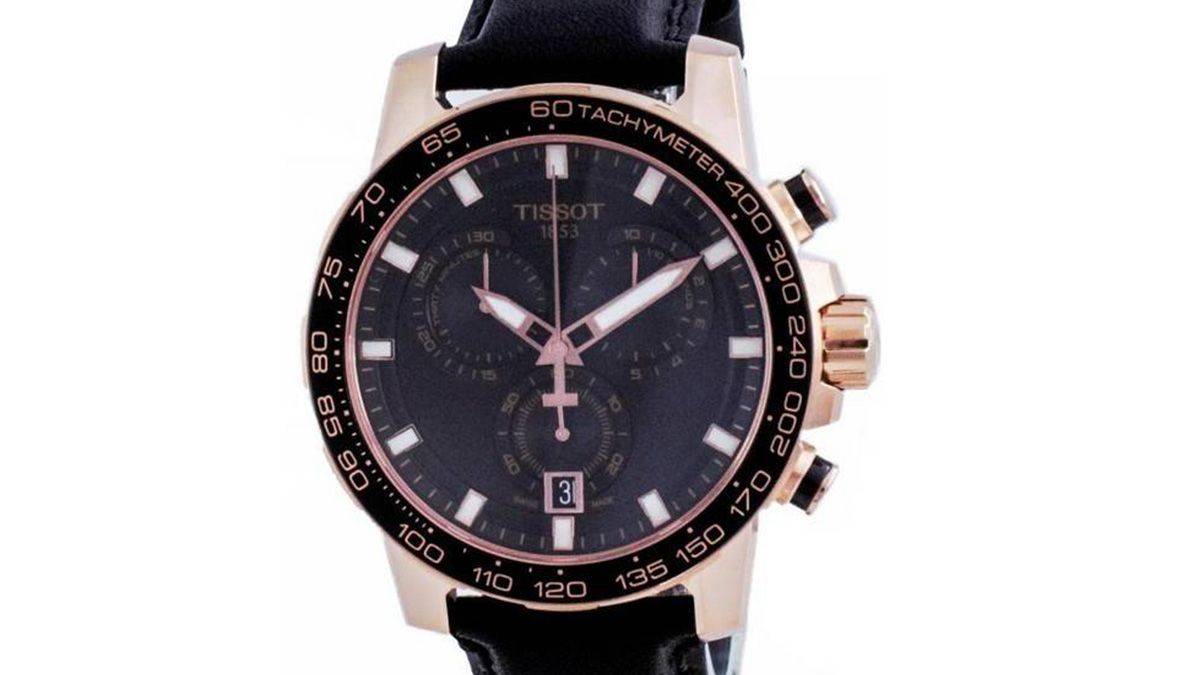

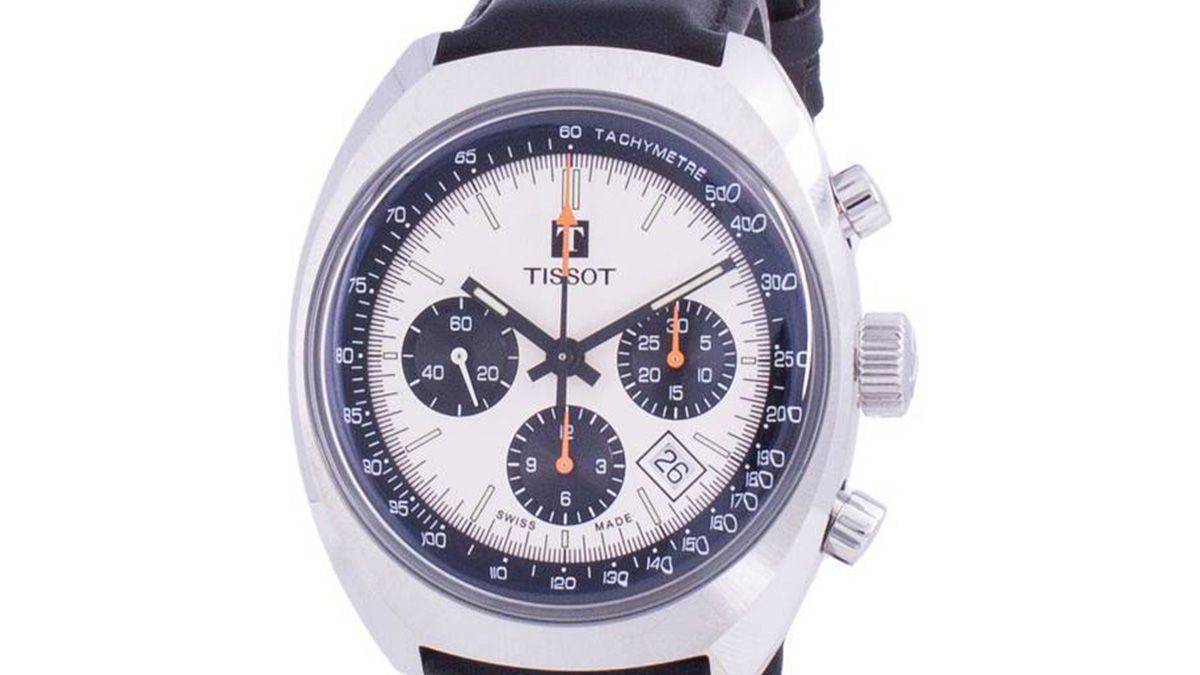

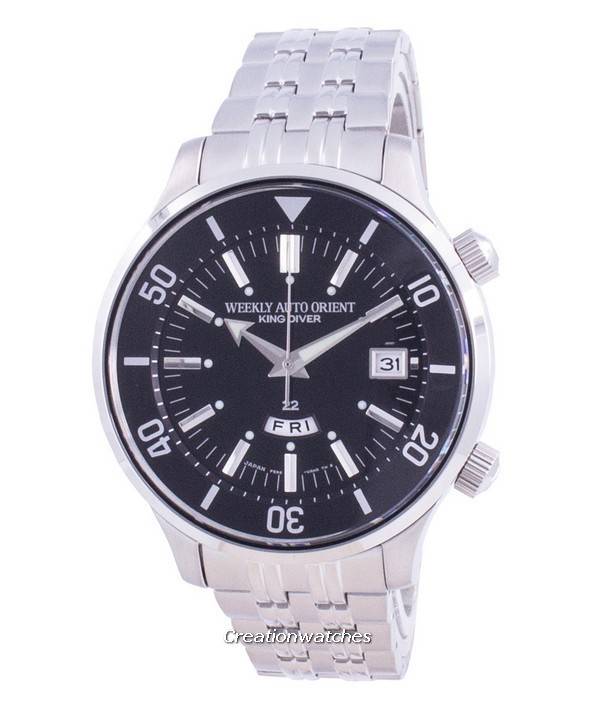

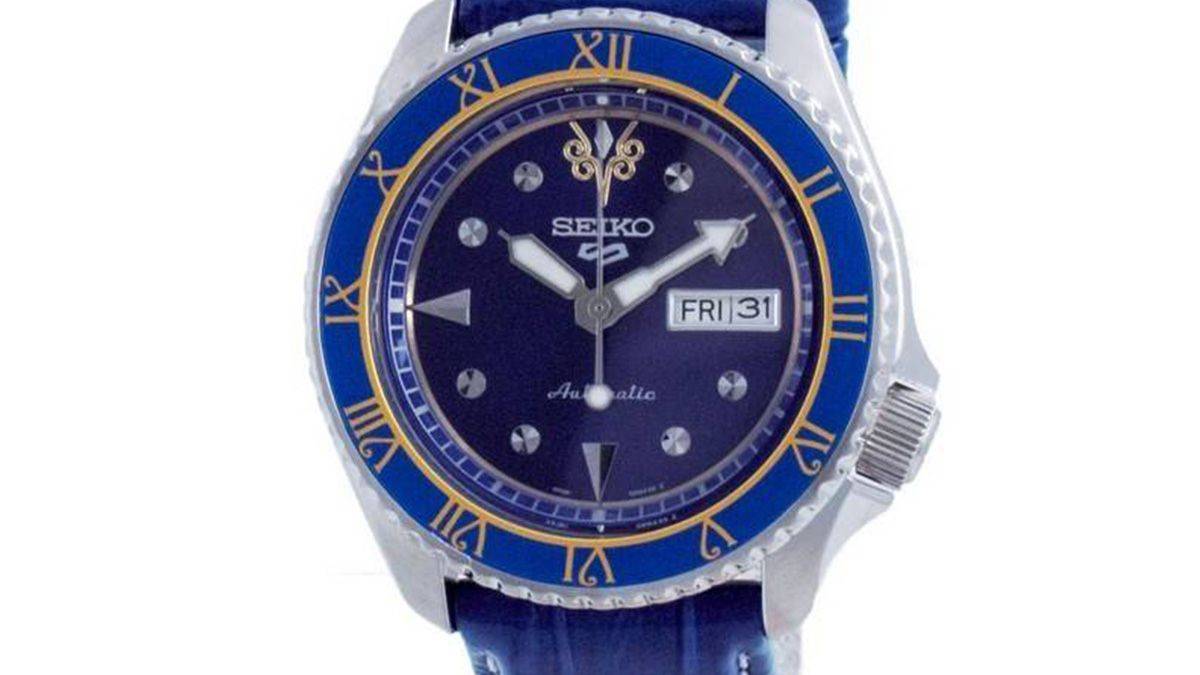

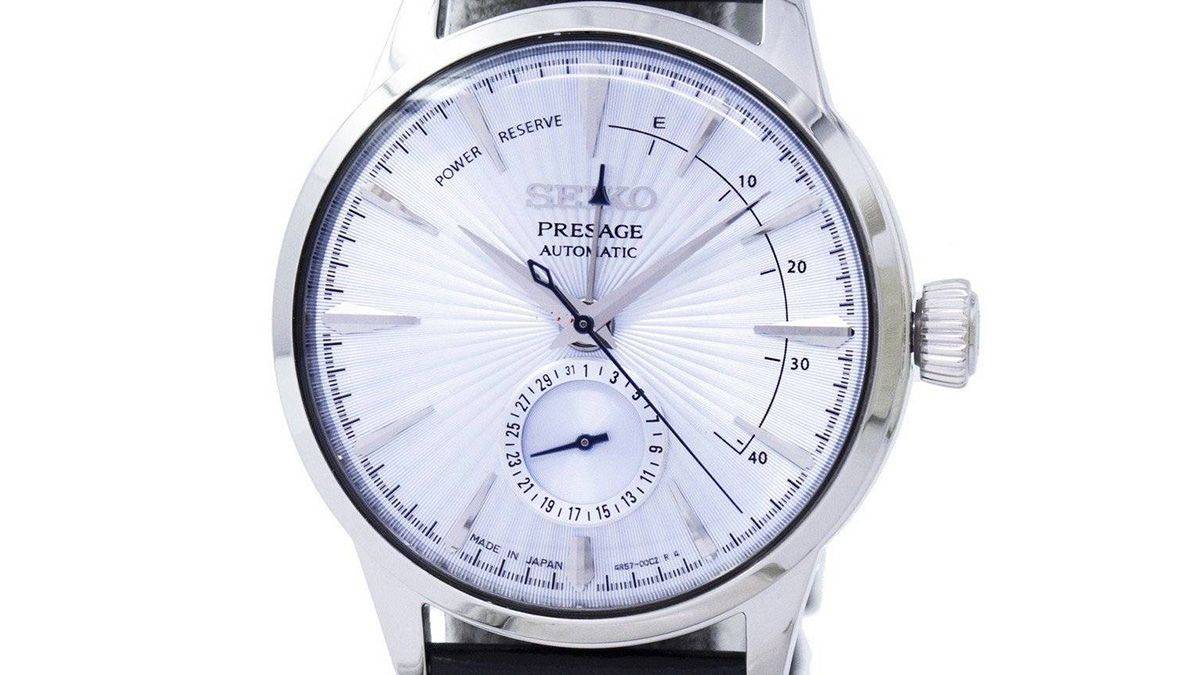

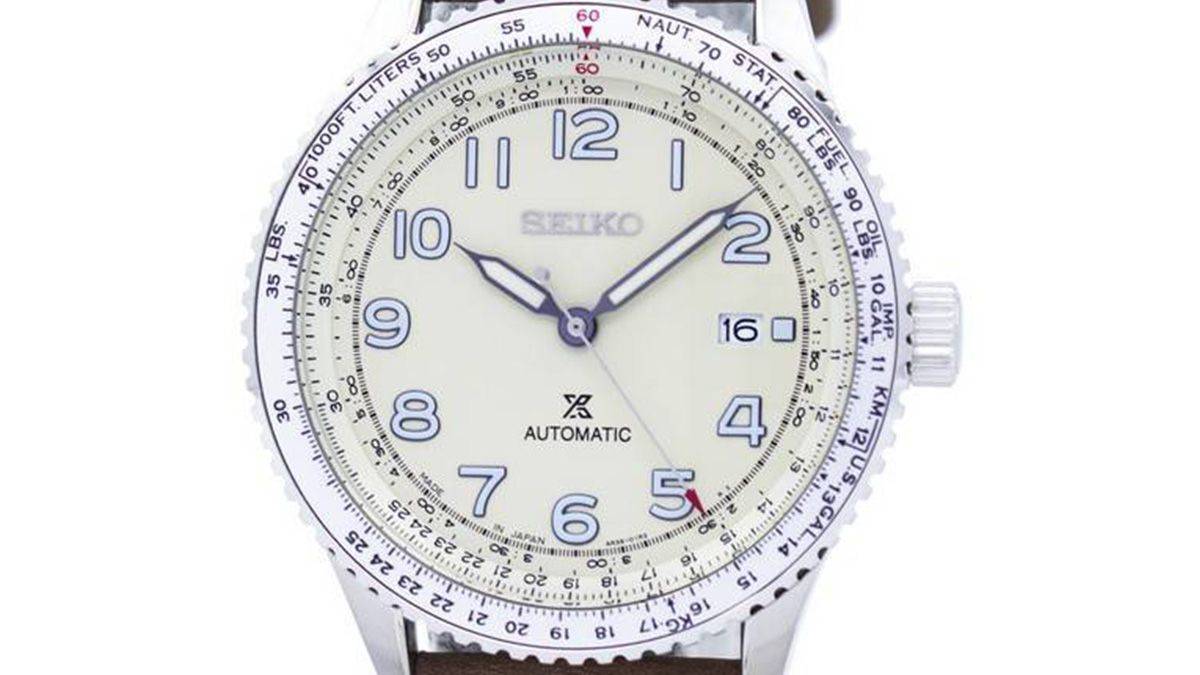

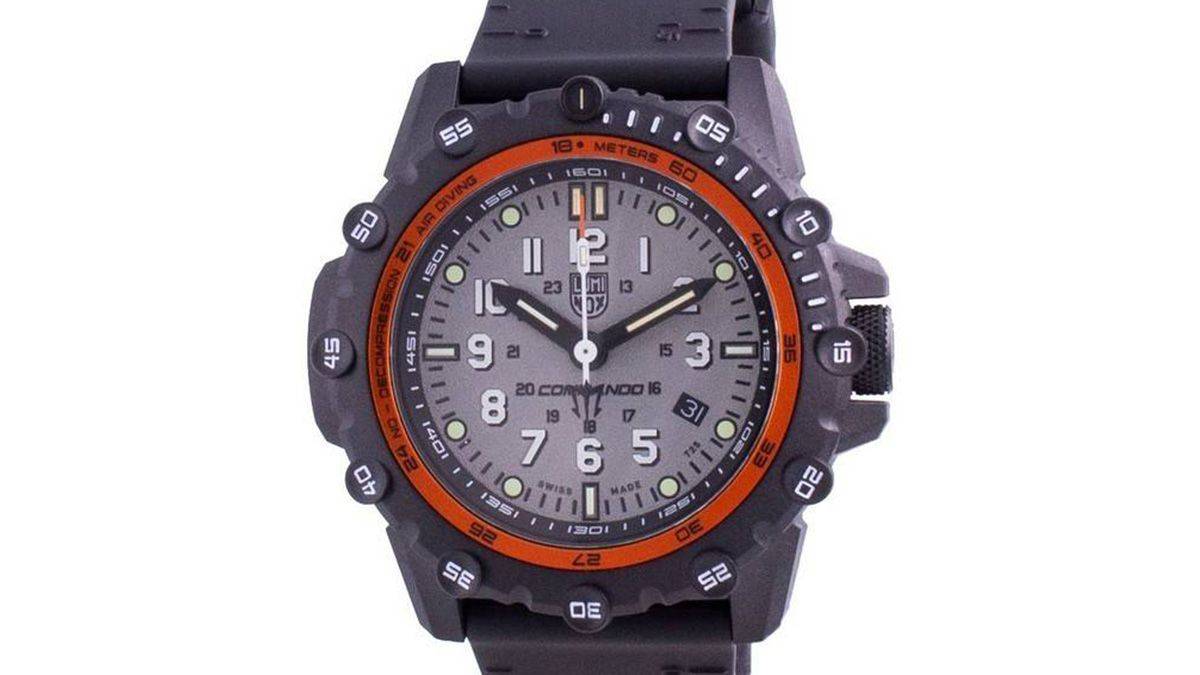

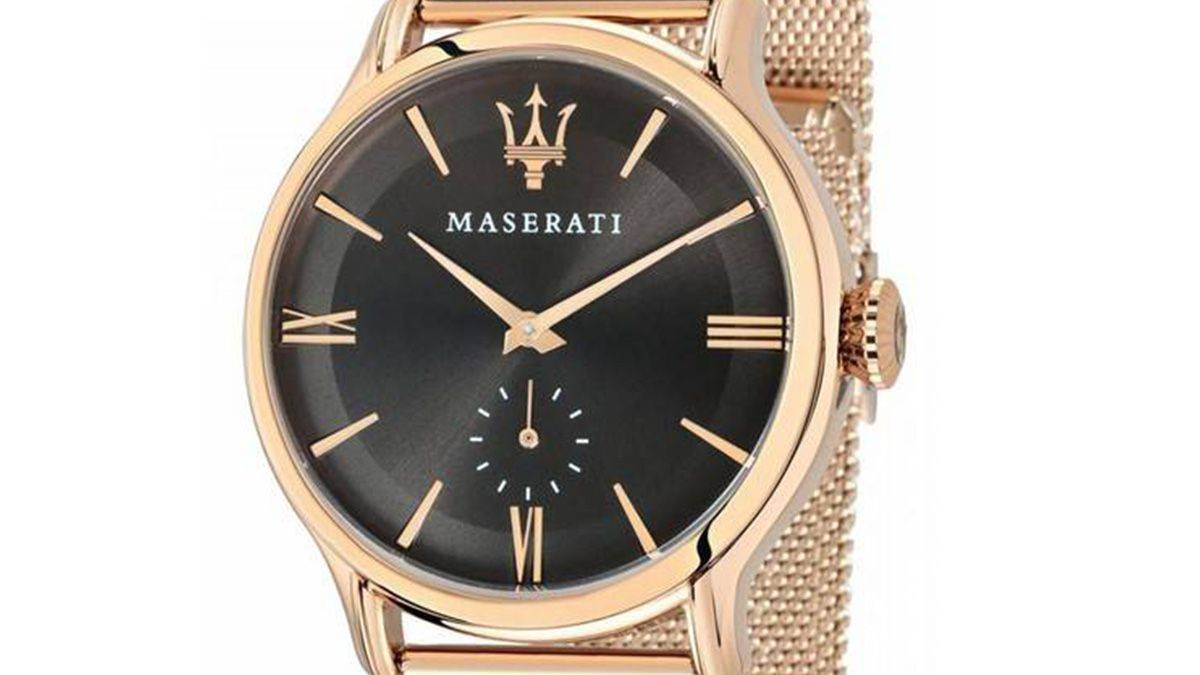

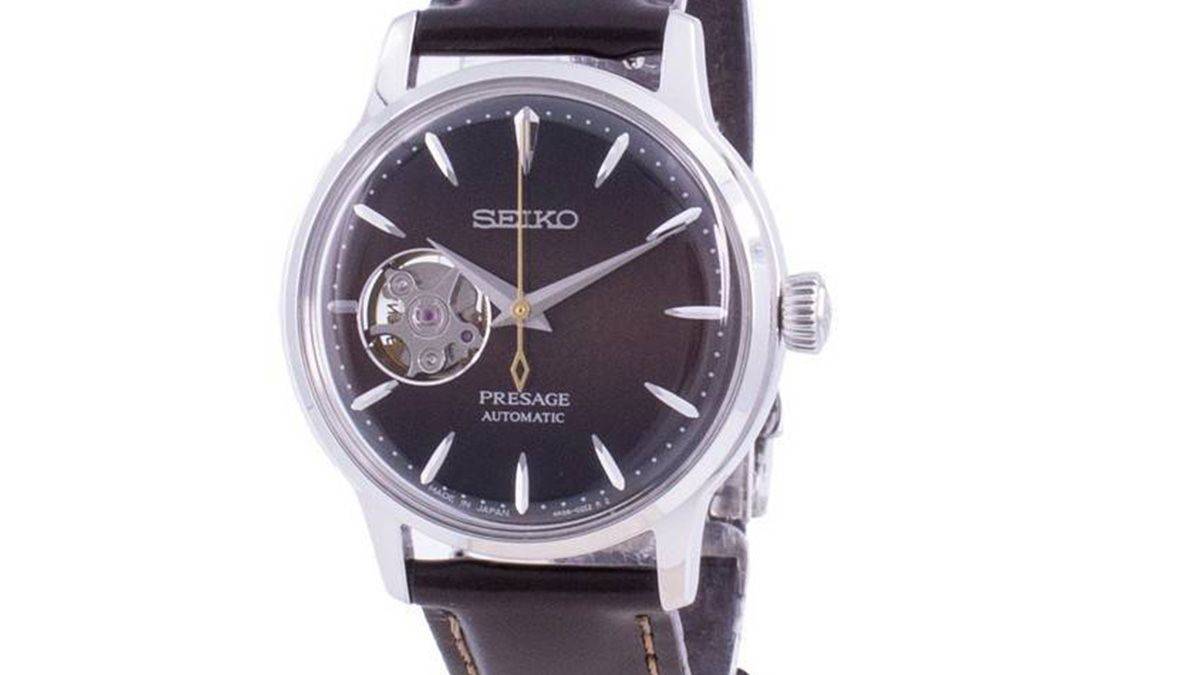

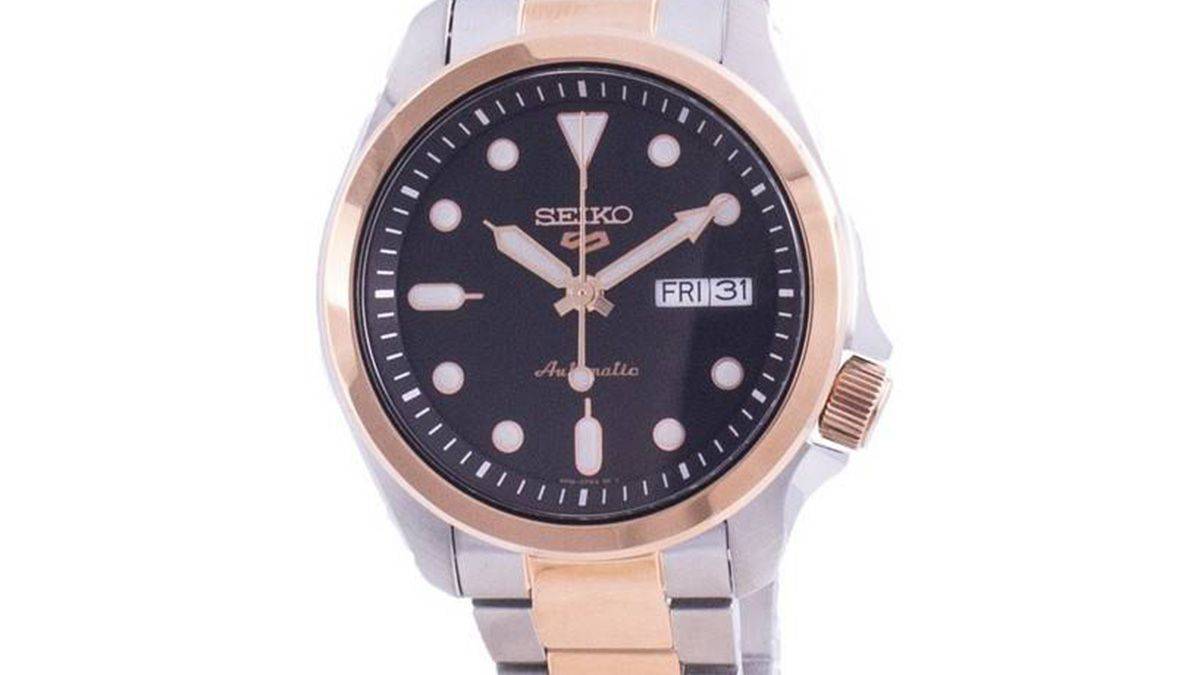

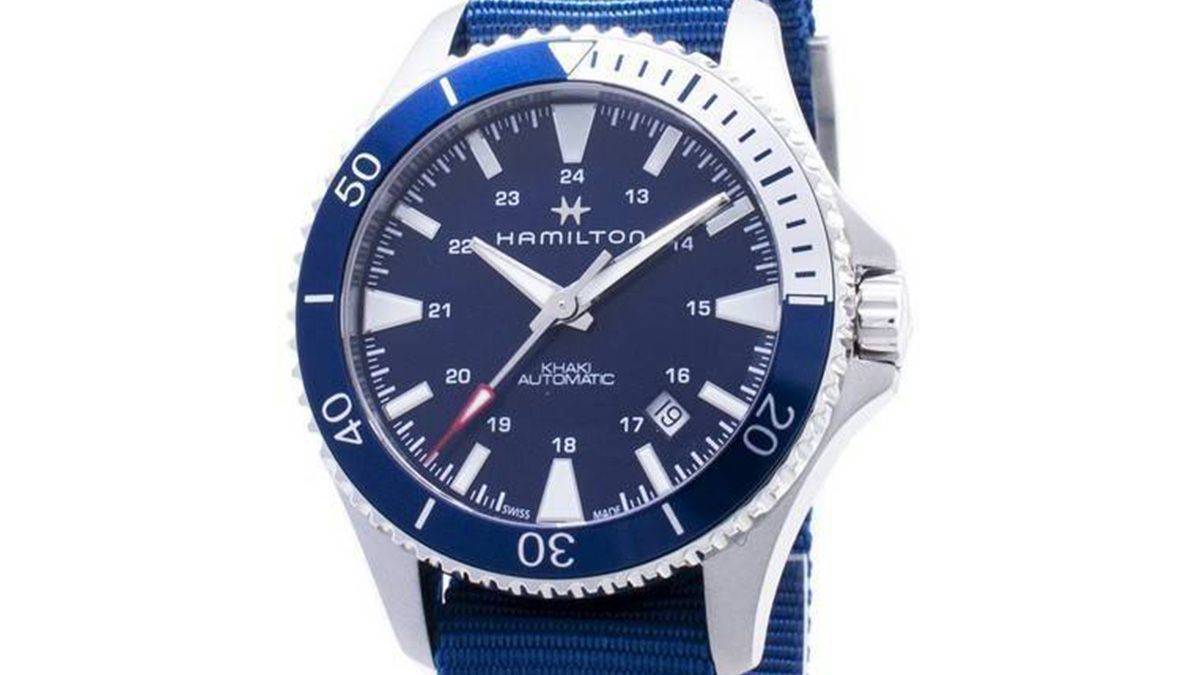

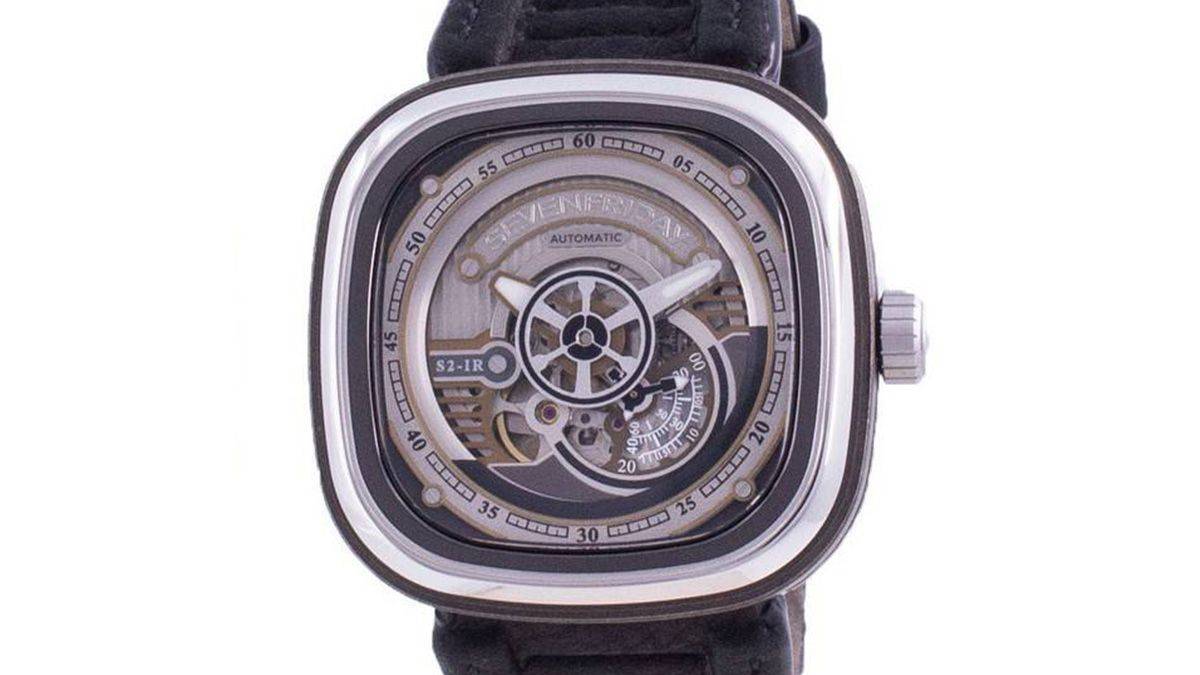

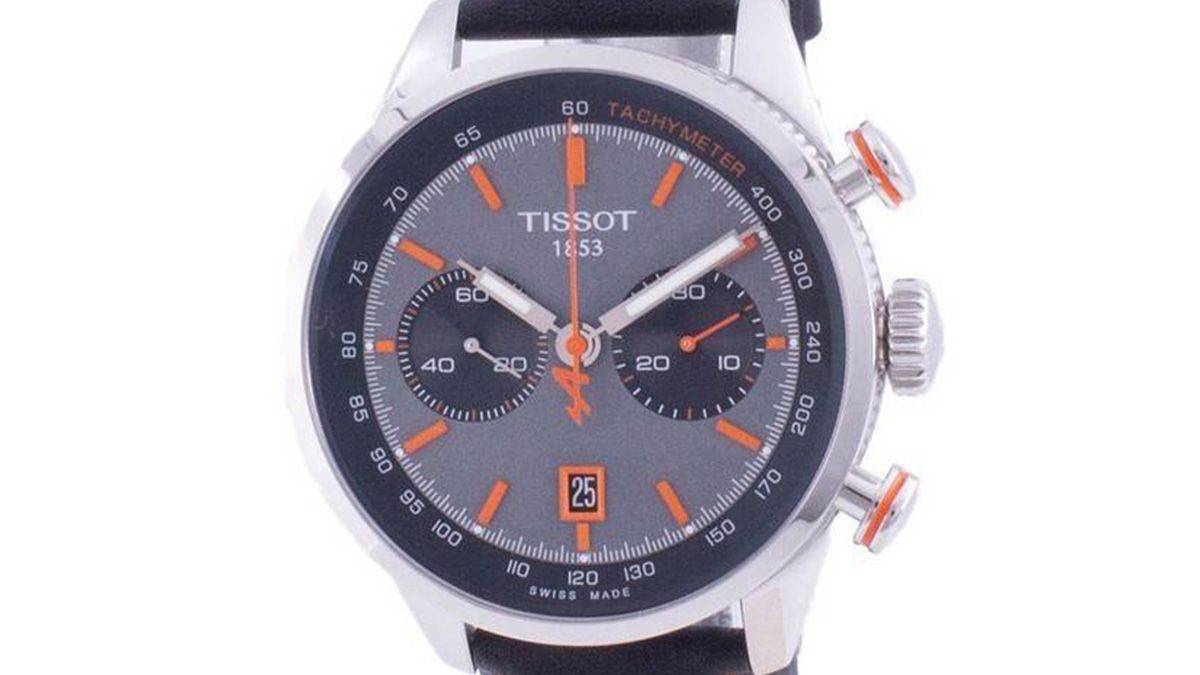

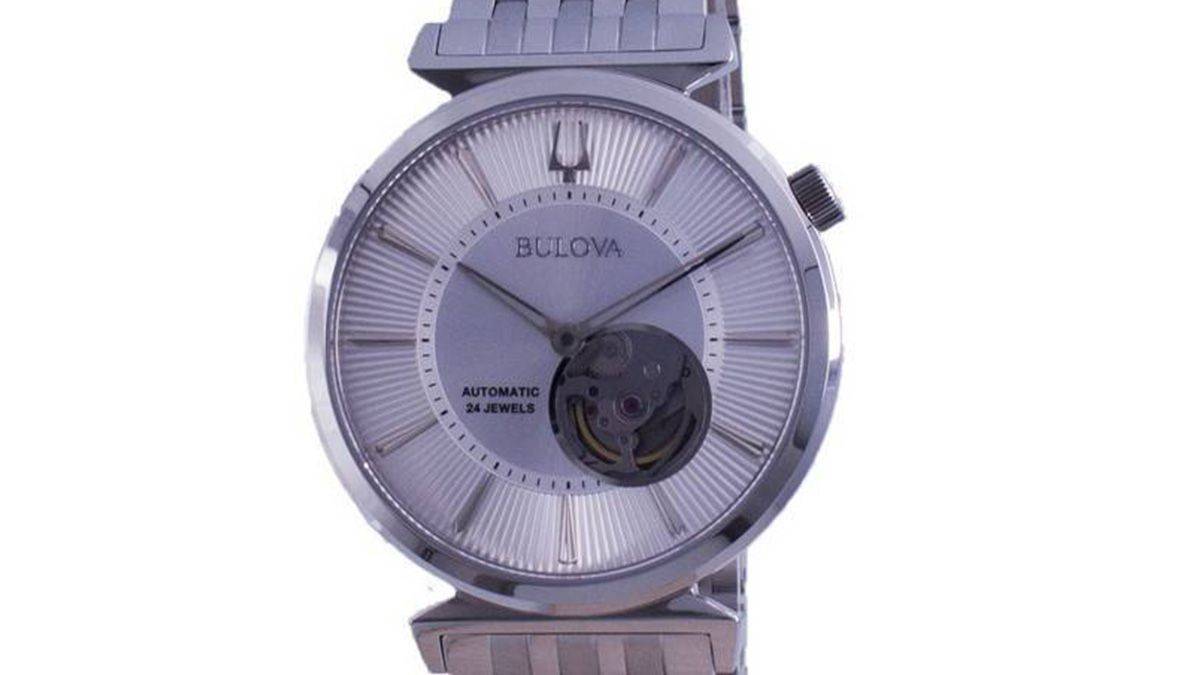

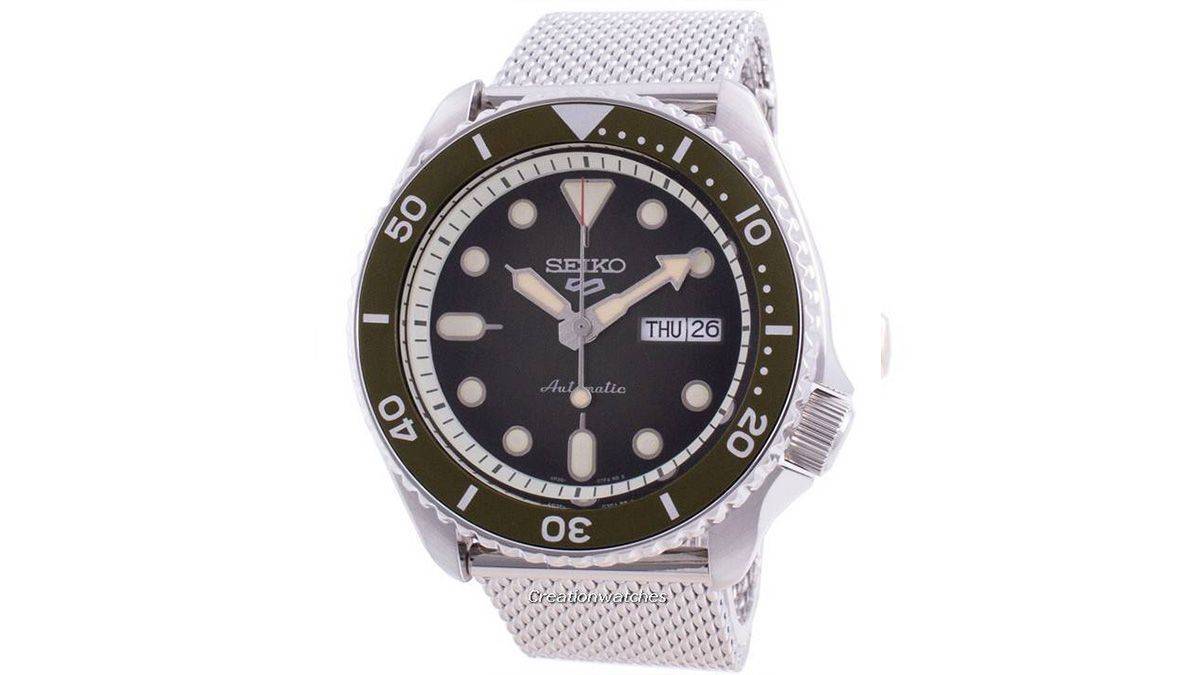

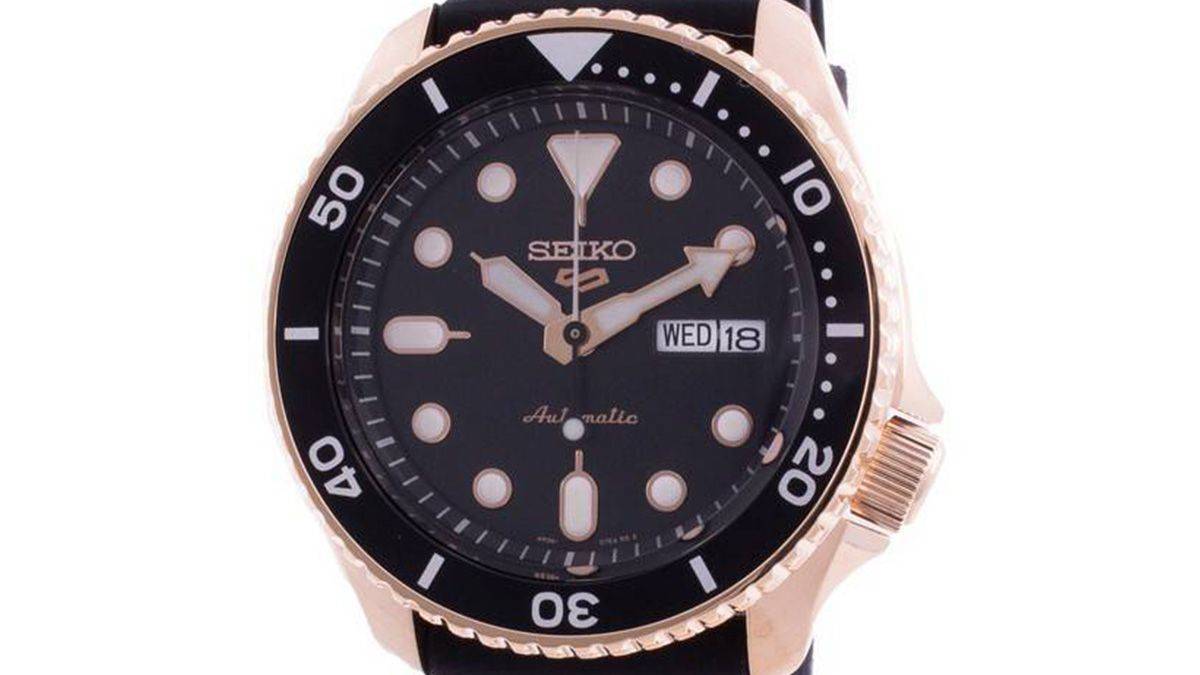

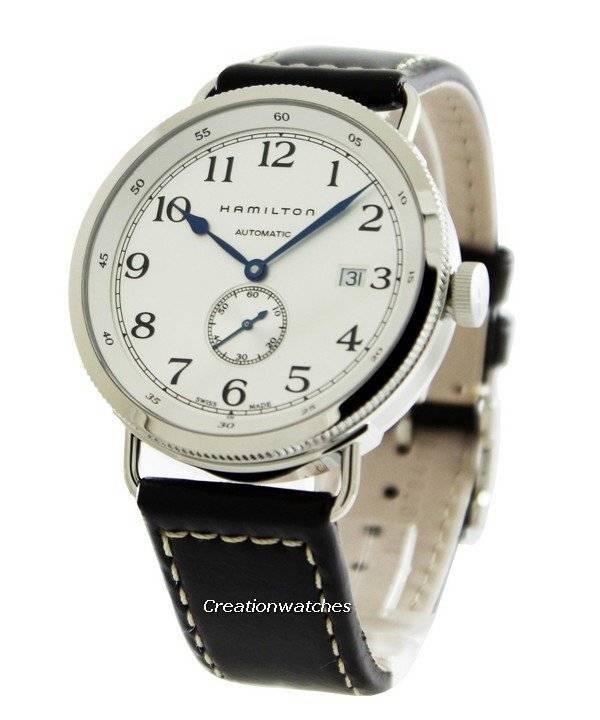

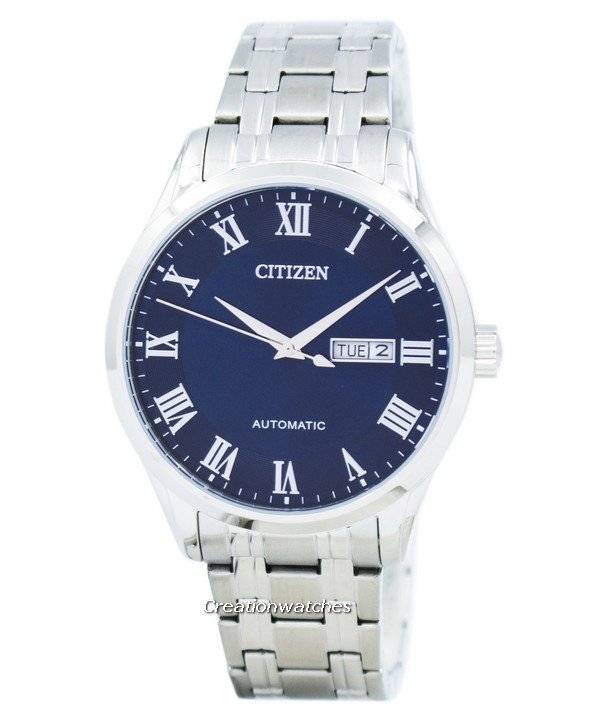

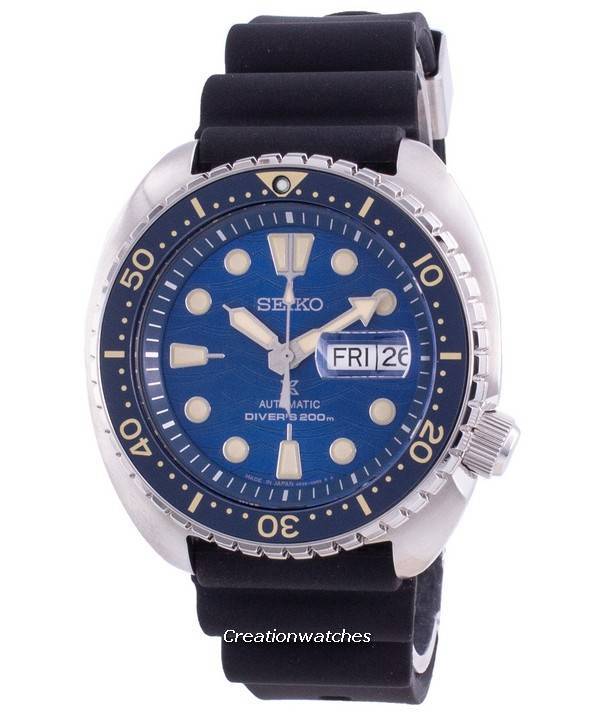

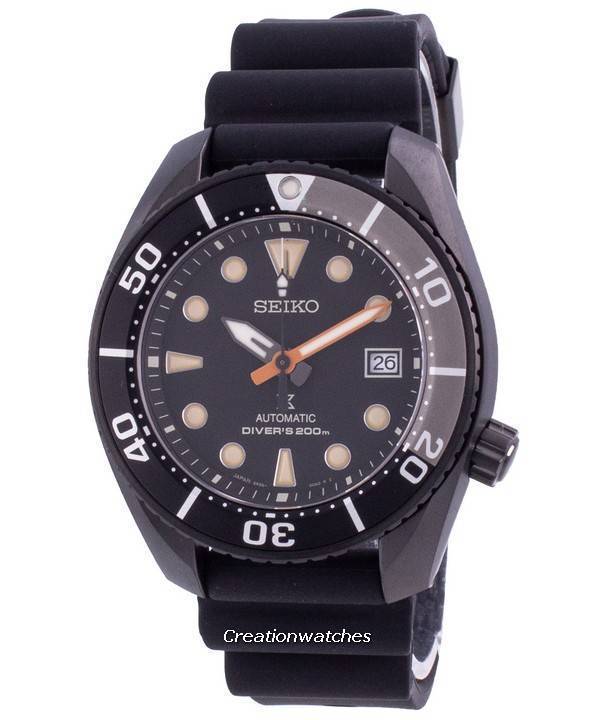

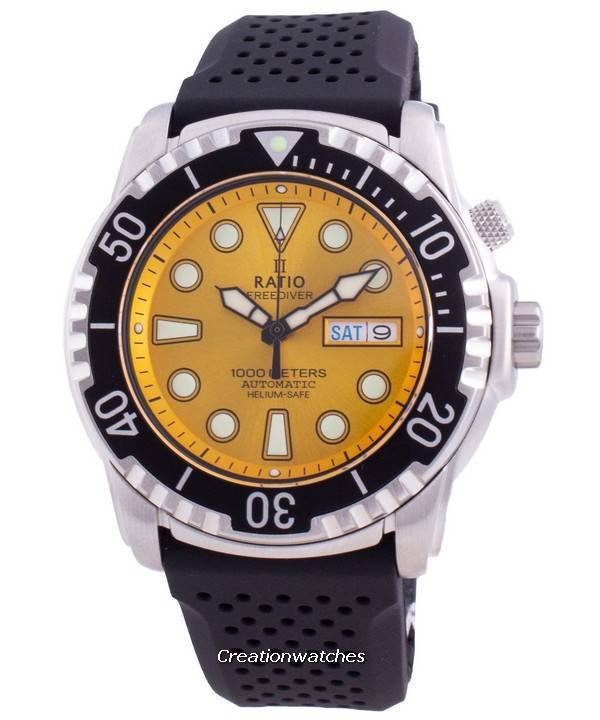

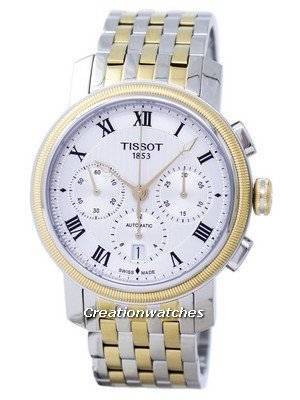

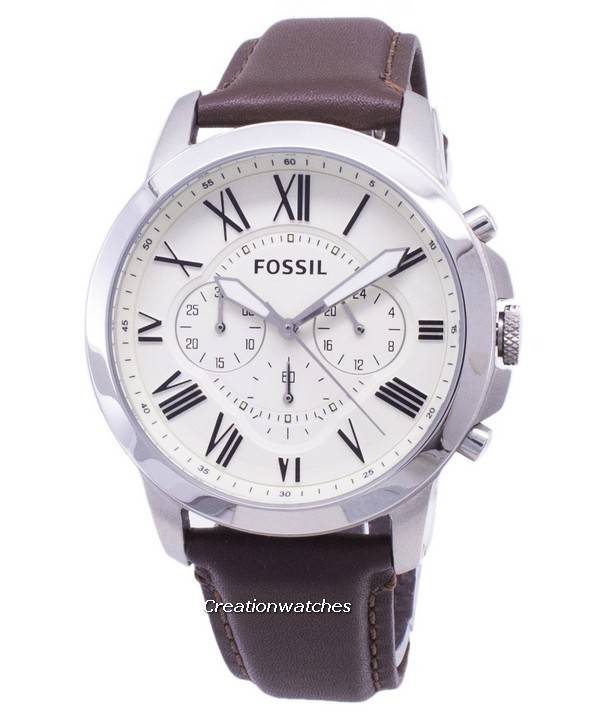

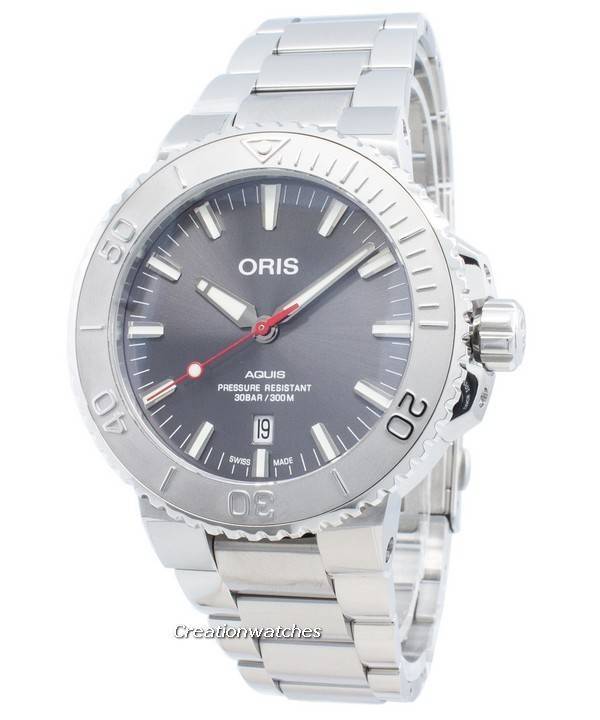

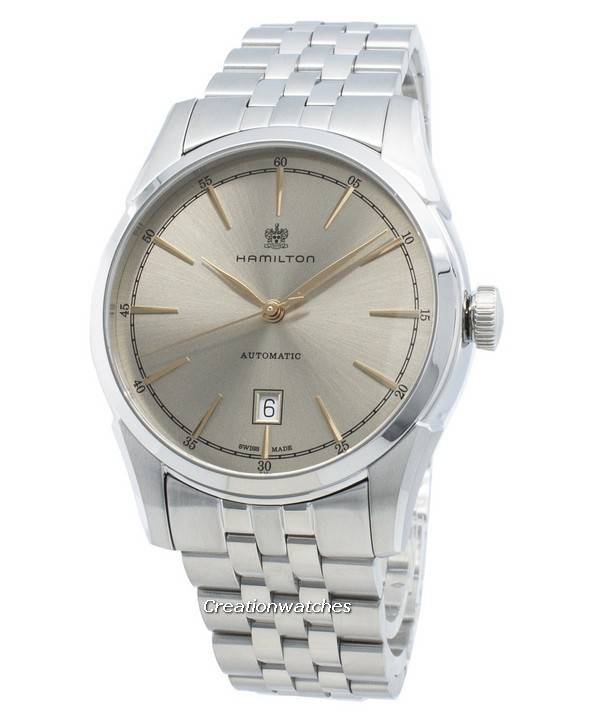

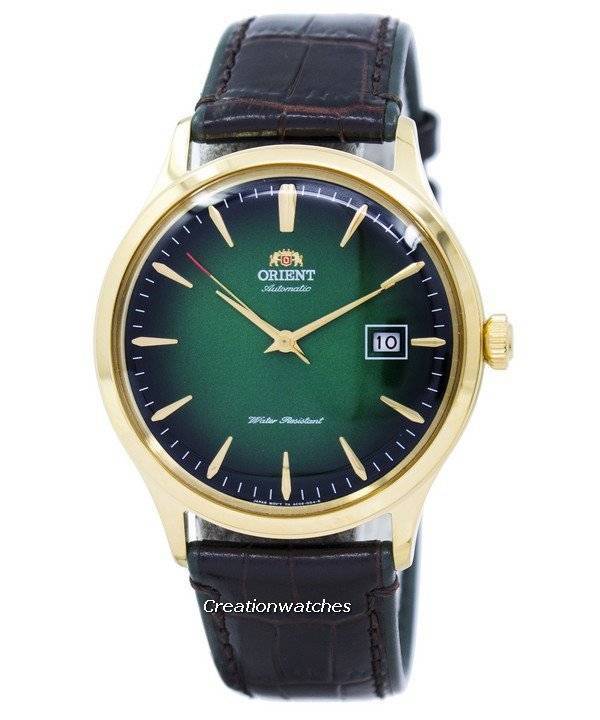

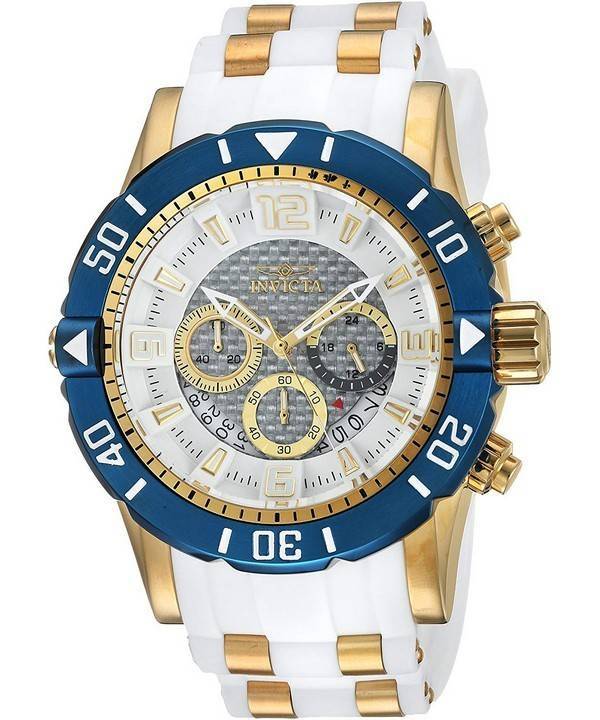

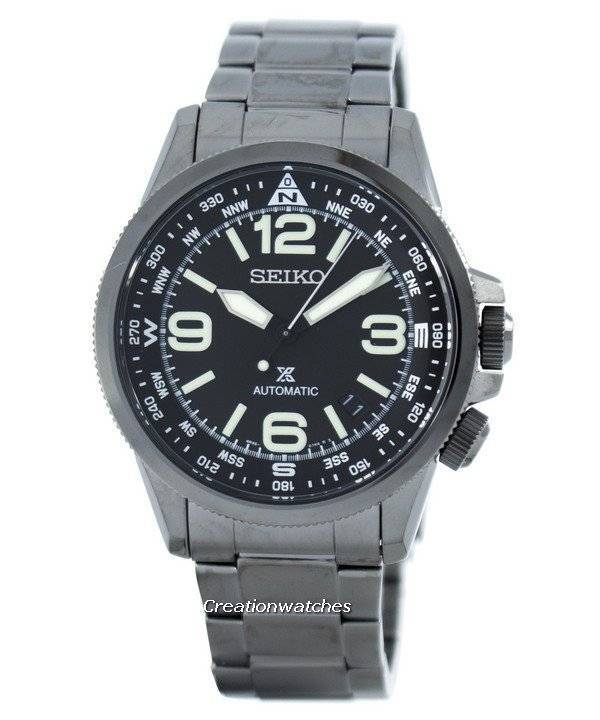

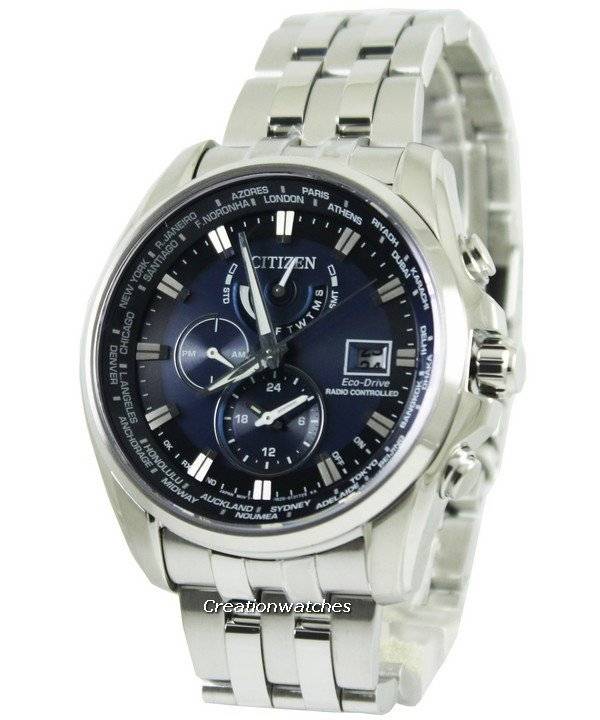

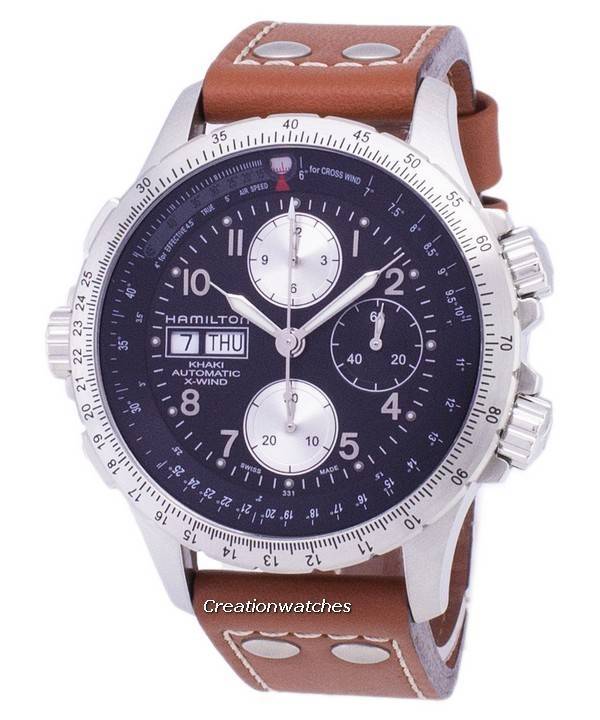

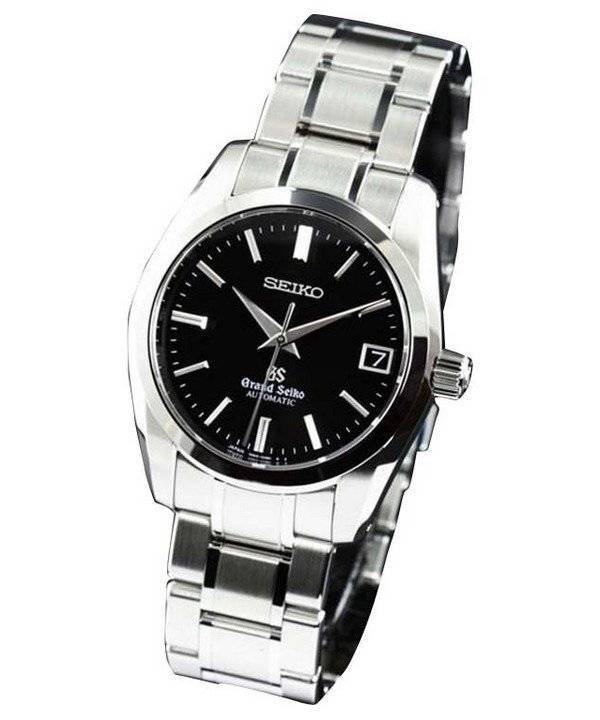

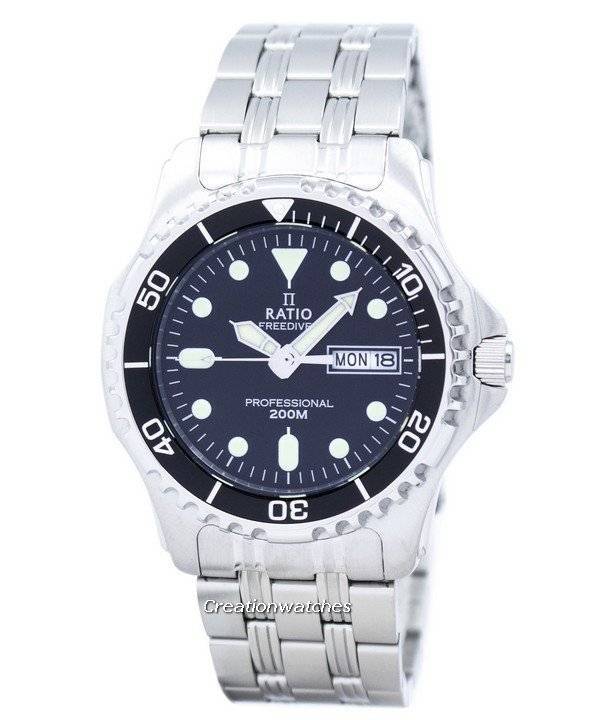

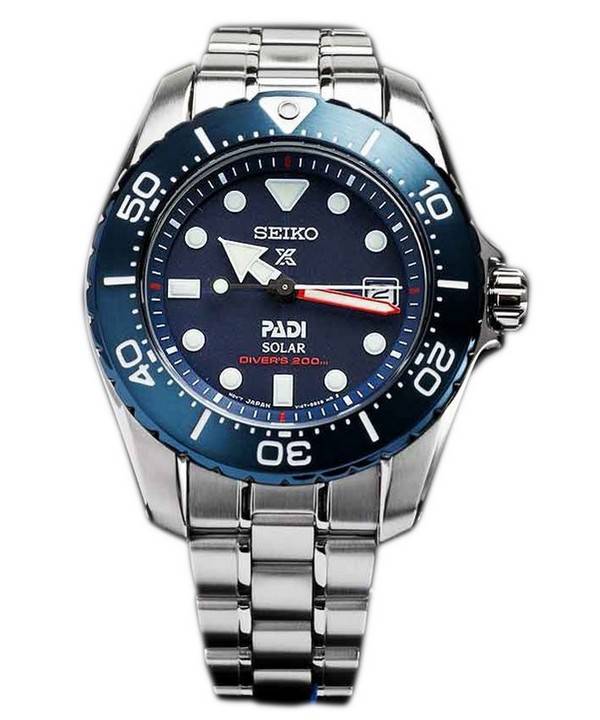

Watch(es) mentioned in this post are listed below. Click to see details and buy them: