- March 2, 2022

- Watch Gonzo

- 0

CLEANLINESS IS A STATE OF PURITY, CLARITY AND PRECISION.

Suze Orman (American financial advisor, author, and podcast host)

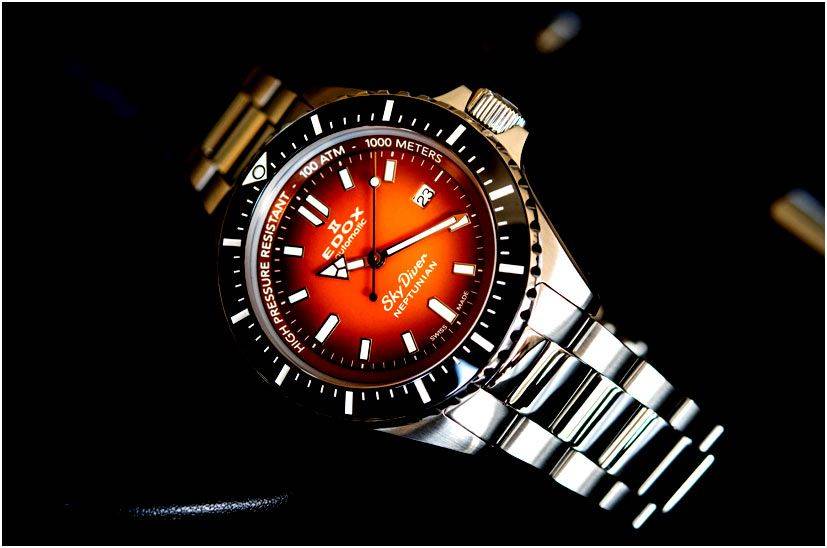

A PRELUDE TO REGULAR WATCH MAINTENANCE

here are numerous real-life stories about watches that survived absolute Hell – whether at Saigon or in Afghanistan or Benghazi – and still keeping on ticking, maintaining perfect time; however, it is not good for the watch not to get some tender, loving comfort in return after hard days of labour, irrespective of how good or solidly built the watch might be. Similarly, a watch running for a decade without some TLC is equally detrimental as lubricating oils turn dry; the metal parts wear off and static parts often catching rust. Problem is, you won’t notice until one fine morning you wake up and discover your watch lying dead by your side and then, you shell out considerable amounts of money (depending upon the brand) to get it back in a working condition. The money apart, it also costs you time and cause you stress. And certainly, it translates in sacrificing the wearing pleasures, which might again be anything between a few days and a few months; a replacement or a repair, whichever you might choose. Even if the money part doesn’t bother you, there might not be ready stocks available; worse, your watch is out of production and spares are no more available. In that case, you need to bury and forget your precious wrist-wear, which is, an extremely painful affair.

You also never know if the same model would be available locally even if it’s around in the assembly line.

A stitch in time saves nine. That’s how these nine points go. Hope they don’t hurt you as much as the real thing would.

T.O.C. (TABLE OF CONTENTS)

- Introduction: Making you give some horo-love

- Wind-able vs. automatic – Any different in their upkeep?

- A look at ‘Quartz’ and ‘Meca-Quartz‘

- What about ‘Digital’ and ‘Smart’ watches?

- What you’ll need (and for what)?

- Work-desk manoeuvres (w/checklist)

- Things you must remember before/while cleaning your watch

- Conclusion: At the end of it all

- F.A.Q.

INTRODUCTION: MAKING YOU GIVE SOME HORO-LOVE

Cleaning or servicing your watch is a chicken that can either go roast or roost, depending upon how you do it. Done well and the way it should be, you are good to go for at least another three years (if it’s a somewhat old mechanical watch) and five to seven years if it runs on a more recently-introduced calibres and is not subjected to the rigors of a battlefield on a regular basis.

Now, there are two parts to it: Cleaning the exteriors and cleaning the interiors. While the first part doesn’t take much, the second part will require you to gather some horological knowledge, some added skills, some special tools and a few more components other than lubricating oil; that is, if you are replacing any. This includes the gaskets and the O-rings.

The rule of thumb here is: One shouldn’t wait for a mechanical watch to stop or develop a fault before you decide to service it. For battery-operated quartz watches, a battery change occurs every three to five years and therefore, also the servicing. With mechanicals and Solar watches, people tend to overlook the servicing part because they keep on working until that very day, when everything suddenly nosedives.

Reasons are many, but first and foremost, it’s the sweat, dirt and grime that accumulate at every contour of the watch; mostly, around the juncture where the case-back meets the case. It also accumulates around the crystal and the underside of the crown; however, they wouldn’t pose any problem if they didn’t wear the sealing gaskets off, which is quite a rare phenomenon. For screw-down crowns also, dirt and sweat collects around the threads, which affects the water resistance of a watch heavily.

Considering all these factors, you must make sure you pour some TLC on your loving pieces at regular intervals, which are as follows:

| Age of your watch | Mechanical Automatic | Mechanical Hand -wind | Battery-operated quartz | Meca- quartz | Solar Quartz | Digital |

| <5 years | 1st service: At the end of 5 years; extendable to 7 years (under normal use) | 1st service: At the end of 3 years; extendable to 5 years (under normal use) | To be serviced whenever you are changing the battery. | Every seven years; main capacitor lasts for 15-20 years. | Every seven years; main capacitor lasts for 15-20 years. | Every seven years; main capacitor lasts for 15-20 years. |

| 5-10 years | Once every 5 years | Once every 3 years | ||||

| >10 years | Once every 3 years | Once every 2 years | Every 18 to 24 months |

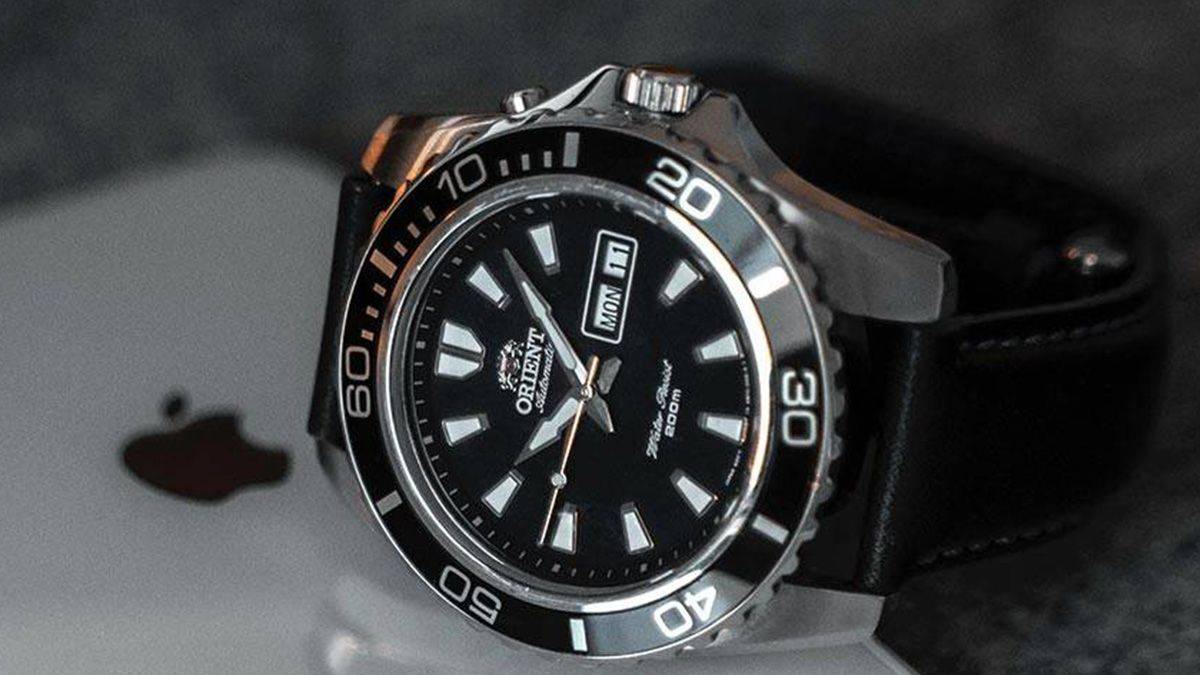

WIND-ABLE VS AUTOMATIC: ANY NOTABLE DIFFERENCE IN THEIR UPKEEP?

Let’s look at their similarities and differences first. This is vital since it will give you an idea about how things work within, which in turn, will help you to get a better grip on the job. Once you are done with the aesthetic clean-up, you’ll have a fair idea more or less about what to do with your watch’s innards.

Let’s look at their similarities and differences first. This is vital since it will give you an idea about how things work within, which in turn, will help you to get a better grip on the job. Once you are done with the aesthetic clean-up, you’ll have a fair idea more or less about what to do with your watch’s innards.

Another thing is: For servicing the inside of the case, the movement needs to be taken out. There’s no point in servicing the movement every year or two years when you wipe the inner walls of the case, the case-back and the glass. Our advice:

Take things apart every three years and give the watch a solid maintenance job. That’s not asking for too much. For every 1095 days of relentless working, it deserves 10 days of complete rest. This is because the ball-bearings may be the best friction-removing invention so far, but not the other metal parts that slide against each other in full contact. All the contact points and surface areas need it more than the balls rolling in a set track.

What you need to take apart? Here starts the grind.

But before that! The frequency of servicing, tearing the movement down and cleaning, oiling, adjusting etc. and building it up again is the same, whether automatic or manual winding. Both will require a proper lubrication job on the winding mechanism and the gear train but the type of oil you’ll use will make a lot of difference. Not talking about it being synthetic or natural; it’s about the quality and freshness.

The other difference is – You don’t need to worry about the rotor in a manual winding movement.

Also, for frequent water contact, you may want to have the seals checked quarterly or semi-annually not just for hand-wound or automatics but also for the other types.

So, to the grind now!

Manual wind and automatic movements are very similar; the only difference between the two is that the automatic has a few extra bits added to a manual movement to make it wind automatically. The automatic winding system adds complexity to a watch and therefore, they will require (at least theoretically) more frequent service to remove the potential for issues.

Also, a lower beat movement wouldn’t need to be serviced quite as often as a higher beat movement. A movement beating at 18,000 bph will have less wear (under normal conditions) than movements beating at 28,800 bph.

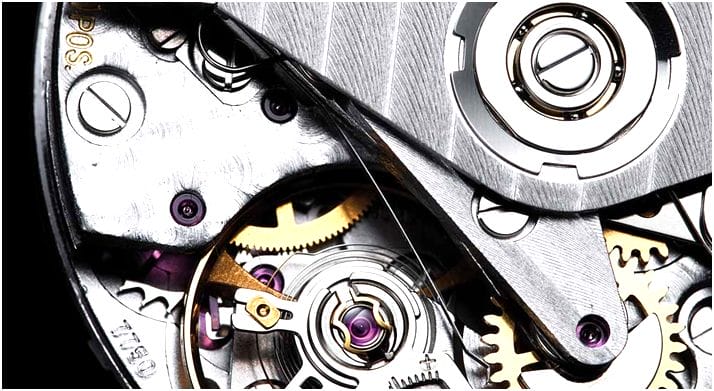

There are over 180 parts in a mechanical watch that you’d need to lubricate. This includes springs, wheels, escapement, pinions, pivots, jewels, gears and plates and rotor, in case of automatics. However, both automatics and manual-wind movements have quite a few, very small, bearing surfaces that require lubrication to allow the surfaces to slide across one another. We divide them into groups and individual parts and give you a summary of what they do.

- Individual components

- Main Plate / Base Plate: The main plate is the primary piece of metal that holds all the other parts of a movement together. Each part is mounted between these two plates.

- Balance wheel – A hollow rotor-like structure; a part of the escapement assembly which, in combination with the hairspring, oscillates back and forth to help click the pallet fork into the correct place.

- Escape wheel – An unusual-looking gear receiving momentum from the mainspring and making the balance wheel, hairspring and pallet fork work with it. It determines the timing of the movement.

- Hairspring – A small, thin strip of coiled metal that stays attached to the balance wheel. Its job is expanding and contracting to make the balance wheel oscillate and return to the pallet fork.

- Jewel bearings – These are small pieces of synthetic gems; usually ruby. They reduce friction on key components, thus increasing the lifespan of the bearings.

- Oscillating weight/rotor – Found only in automatic and sometimes, in hybrid wristwatches. This typically crescent-shaped weight sits at the base of the movement, moving freely and winding the mainspring as your hands move. It rotates the central staff attached to the winding mechanism.

- Setting jumper & lever – These two components together allow for multiple (time/day/date, for example) functions and prevent accidental adjustments to the time.

- Spring barrel – The mainspring housing with a toothed circumference like a traditional gear, it typically pairs with a cover, to contain the mainspring inside.

- Supporting structure – A variety of specially shaped metal plates that help hold the components of the movement in place. The largest ‘main’ plate acts as a base, while the second-largest plate known as the ‘barrel bridge’ holds the mainspring with its associated components. There are smaller sections, including the ‘wheel bridge’ which supports the wheel train arrangement, the pallet bridge which holds the pallet fork and the balance bridge above supporting the balance wheel and the remaining regulator assembly.

- Stem/Winding stem – A rod attached to the crown that transfers the crown inputs to the mechanisms within the movement. The winding stem comprises many different surfaces (cylindrical pivots, a square end, cut-outs for engaging posts to engage) all integral to its many functional purposes and a threaded section for where the crown attaches. The square end interlocks with the winding and setting mechanisms.

- Winding pinion – A toothed wheel that looks like a gear; a part of the mainspring assembly; features both radial and perpendicular teeth through which the winding stem fits. Its function is evident from its name.

- Yoke & sliding pinion – These two are also associated with the crown arrangement, determining the functions to be enabled when the crown out or pushed back. Engaging the setting jumper makes the spring-loaded yoke move the sliding pinion and engage with specific gears including the motion works (details below).

- Core machinery

- Crown Assembly – This you can view from the outside; the crown being the medium between the mechanism and the wearer; connected to the winding stem. The crown is pulled out to access different settings (time and date adjustments, for example) and to manually tighten the mainspring and provide power to the movement.

- Mainspring – This will be a flat, coiled strip of pure, hardened metal, metallic alloy or silicon or some other synthesized material, 20 to 30cm long; contained within the toothed mainspring barrel. At its centre sits the winding pinion, attached to a ratchet wheel and the click assembly sitting below and ensuring the pinion’s unidirectional rotation. Its job is preventing the mainspring from unwinding; in simpler words, the ratchet and the clicker preserve the momentum from the mainspring and release it via the mainspring barrel.

- Gear/wheel train – Positioned next to the mainspring, the train is a series of interlocking gears driving the timekeeping hands as well as the other wheels within the movement. The centre wheel is directly driven by the mainspring barrel that turns fully once every hour, thus turning the minute hand. The motion is carried forward by the third wheel to the fourth wheel rotating once every minute and therefore, drives the seconds-hand (if present). Each of these gears runs from a central axle mounted on a synthetic jewel bearing, which massively reduces friction and wear.

- Escapement assembly – The escapement assembly utilises jewels to reduce friction and wear and houses thr shock absorbent mechanism. You’ll find this at the end of the wheel train. The most delicate part within a watch movement, the escapement assembly controls the flow of power from the mainspring, ensuring that it doesn’t uncoil and release its entire power at once. Instead, the stored energy from the mainspring is transferred to the escape wheel via the gear train. The escape wheel rotates and pushes against the pallet fork, flicking a section of the balance wheel, whose rotations are again controlled by the hairspring. It contracts and expands to oscillate the balance wheel back towards the pallet fork, clicking it into a second position and releasing the escape wheel momentarily and then holding it in place once more with the other prong of the pallet fork. It stops the escape wheel and the other gears from spinning freely and takes place within fractions of a second. The frequency of this process determines the beat-rate of a movement; indicating how many times the seconds- hand moves per second.

- Motion works – This special set of gears remains positioned next to the centre wheel. The centre-wheel helps provide certain necessary functionalities, the first one being time-setting and next, reduces the speed of rotation of the hour-hand at a ratio of 12:1. In simple words, it makes the hour-hand run 12X slower than the minutes- hand with the help of the cannon pinion, the minute wheel and the hour wheel.

- Complications – These are additional features, ranging from the day/date to 24-hours, chronographs, moon-phases and so on. These we will discuss about in the following post.

A LOOK AT ‘QUARTZ’ AND MECA-QUARTZ

The advantage with servicing a quartz watch is it will have less number of moving parts. They will eventually need servicing but here, we are talking about reasonably higher grade quartz movements and not about those made not to be serviced. They are too simple as creations; so economically priced that you don’t mind throwing the existing one away and getting a new one, even if all that it needs is a battery change.

The advantage with servicing a quartz watch is it will have less number of moving parts. They will eventually need servicing but here, we are talking about reasonably higher grade quartz movements and not about those made not to be serviced. They are too simple as creations; so economically priced that you don’t mind throwing the existing one away and getting a new one, even if all that it needs is a battery change.

Quartz watches, too, suffer from this problem of the buttons or pushers getting jammed and that’s another reason servicing a quartz watch is as essential as it is with an automatic watch, although service intervals could be extended by a fair bit. Though, we recommend a service with every battery change.

Meca-quartz could be of two types: Mechanically charging with a fully quartz timekeeping (and other complications) module or a quartz-regulated electronic timekeeping engine with a mechanical module offering one or more complications; usually a chronograph. Some also call the first type‘auto quartz’.

A quartz movement comprises the following components:

- Battery— Powers the watch; for Solar and Kinetic watches, it is rechargeable; details will

- Integrated Circuit/ C — Gives path to the electrical charge from the battery to flow around and activate and run functions.

- Quartz Crystal — Vibrates (@32,768 Hz/sec) when exposed to the electricity from the battery, generating voltage.

- Step Motor(s) —Converts the electrical pulses from the quartz vibrations into mechanical power to drive the complications.

- Dial/Gear Train — A series of gears regulating energy from the stepping motor to control the functions.

- Rotor – This rotates just like in an automatic watch and charges the rechargeable battery inside.

Now, let’s see the areas where quartz watches usually fail and ask for a service.

- Dirt accumulation within the movement might lead to mechanical problems. Broken or worn out cog wheels are very rare.

- Salts and oxidation deposits around the battery compartment.

- Wire-damage of the step motor coil during changing the battery.

- Malfunctioning fork quartz crystal due to extreme temperature changes or intense mechanical shocks. Affects the accuracy of a watch drastically.

- Short-circuiting of the circuit board.

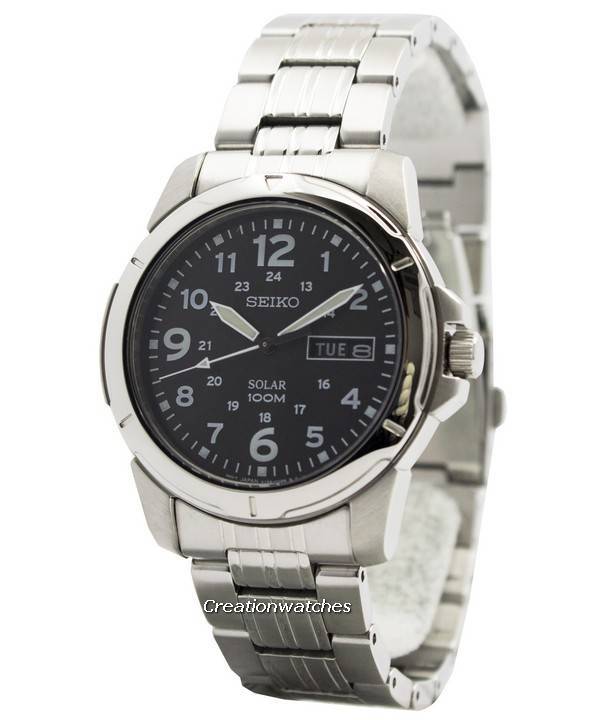

WHAT ABOUT SOLAR, ‘DIGITAL’ AND ‘SMART’ WATCHES?

There’s not much difference between the quartz watches we spoke about above and the solar, digital and smart watches we are going to discuss now. They too stop once out of power, may suffer from water related damages; there might be dirt and grime clogging the buttons or maybe even suffer from malfunctioning sensors! In that case, there’s nothing much you can do, for mostly it will be a compact module and you need to take it to the authorised service station. However, following a few things will offer greater protection to your watches thus lengthening their life and cutting down on maintenance schedules.

There’s not much difference between the quartz watches we spoke about above and the solar, digital and smart watches we are going to discuss now. They too stop once out of power, may suffer from water related damages; there might be dirt and grime clogging the buttons or maybe even suffer from malfunctioning sensors! In that case, there’s nothing much you can do, for mostly it will be a compact module and you need to take it to the authorised service station. However, following a few things will offer greater protection to your watches thus lengthening their life and cutting down on maintenance schedules.

Do not tinker with Solar watches under their hood. They give users many years of uninterrupted use with regular external cleaning; best, if wiped and brought to a shine with soft, dry cloth after every use. In fact, that holds true for every kind of watch. That way, the service interval of the Solar watch will extend way beyond the six to 7 years span that most manufacturer’s claim. Those often exposed to harsh environmental surroundings need servicing and pressure tests every two years. That too applies for every watch, reasonably durable for the outdoors. Others that apply are:

- You shouldn’t press any of the buttons or pull out the crown while the watch is in water or if it is covered in dirt or mud or snow unless they are specifically made for that purpose. Water can also damage the Solar panels if your watch is light-powered.

- The best option always is drying out the internal components to prevent the electronics from shorting out or the displays from getting damaged; to stop future corrosion which would cause a whole lot of other issues you don’t need. Just take the case, glass and movement apart and let them dry thoroughly before using any watch cleaning liquid upon them.

- To deal with impact damages, you might have to replace crystals, the LCD displays, dented or cracked-open cases, broken strap-pins and or torn straps. For integrated LCD displays or malfunctioning sensors, the repair or replacement is possible only with authorised service personnel.

- In case a digital or smart watch loses accuracy, check for water damage, extreme temperature fluctuations. Magnetic fluxes don’t affect digital watches.

- Some minute repairs on your digital and smart watches can be safely done at home, but definitely not all. In reality though, unless you don’t mind risking damaging your watch even further, there’s only a few that are worth trying at home. These will be the inexpensive quartzes with the movements not attached to the inner walls of the case by any means; adhesive or wire. The maintenance and repair are restricted to the case and its components and its battery and connector, which are the most exposed part of the main electronics.

- With a little more knowledge, you might be able to change the LCD or LED panels and the printed circuit boards; maybe even the metal points of contact that activate with the press of the buttons. As for the Solar Analogs, everything about them is almost similar to that of the mechanical analog watches. Even for ana-digis.

WHAT YOU’LL NEED (AND FOR WHAT)

- A dust-free environment: So that dust doesn’t get into the watch and its movement.

- Mild liquid detergent, distilled water, 99% Isopropyl alcohol, any good commercial specially formulated watch cleaning fluid: For cleaning and rinsing purposes.

- Soft, small brushes and Blotting paper: To rub out stubborn dirt and to soak in extra fluid after a rinse.

- Tweezers: Several sizes are available for different jobs. These are used for picking up the different components internal and external; from the sapphire/mineral crystal to the train bridges, base plates or jewels. You can get carbon steel, stainless steel, brass and anti-magnetic varieties. Recommended Sizes: 2, 3, 5 (extremely fine tips), 5″ AA- BR (to prevent risk scratching watch plate surfaces). Bended or damaged tips can be reshaped or can be used for rough work.

- Spring bar tool: To change the straps or bracelets.

- Sharpened peg wood: To clean pivots and other small holes; watch case backs and watch case rims; to dry hands and to clean accumulated grease and dust between bracelet rings.

- Screwdrivers: Decent screwdriver sets are must! Very soft tips could likely slip and cause damage to the watch.

- Hand-lifting tools: Hand levers are essential for removing/putting the hands off/into a watch. These metal rods with tapered flat edged tips come in pairs. The tip is again curved into a blade with a ‘v’ cut at its centre. Available in several sizes for different sized watches. Or, you may go for tools with spring-loaded lifting mechanism. Best, go for both. Standard hand-lifters often come very useful.

- Case opening tools: This includes case knifes (for opening watch cases with snap-on back), a Jaxa-type tool (to open screw-in case backs), hand-held case-back tool, case vice (better if secured in a bench vice), air blower (to blow dry and moist dust and dirt; comes in bellows-style and pump-style.

- Movement holders: To minimise manual holding of the movement once out of the case. Also minimises applying pressure on the watch when taking the components off.

- Loupe: An eye glass with quality optics is essential. Choose between low magnification (x4) and high magnification (x10). You may also get a clip if you wear glasses. Also available with head bands.

- Oil: Today, mostly synthetic oils are used because they resist gumming unlike natural oils which, upon expiry, don’t evaporate like synthetic oils do.

- Oil pot: Keeps dust off your precious oil.

- Oiler: These are fine, specially shaped needles with handles, used for transferring miniscule amounts of lubricant from oil pot to the watch.

Other tools an advanced user might procure are broaches, reamers, pliers, pin vices, files and cutters and measuring equipment. Consult the left table for a comprehensive list.

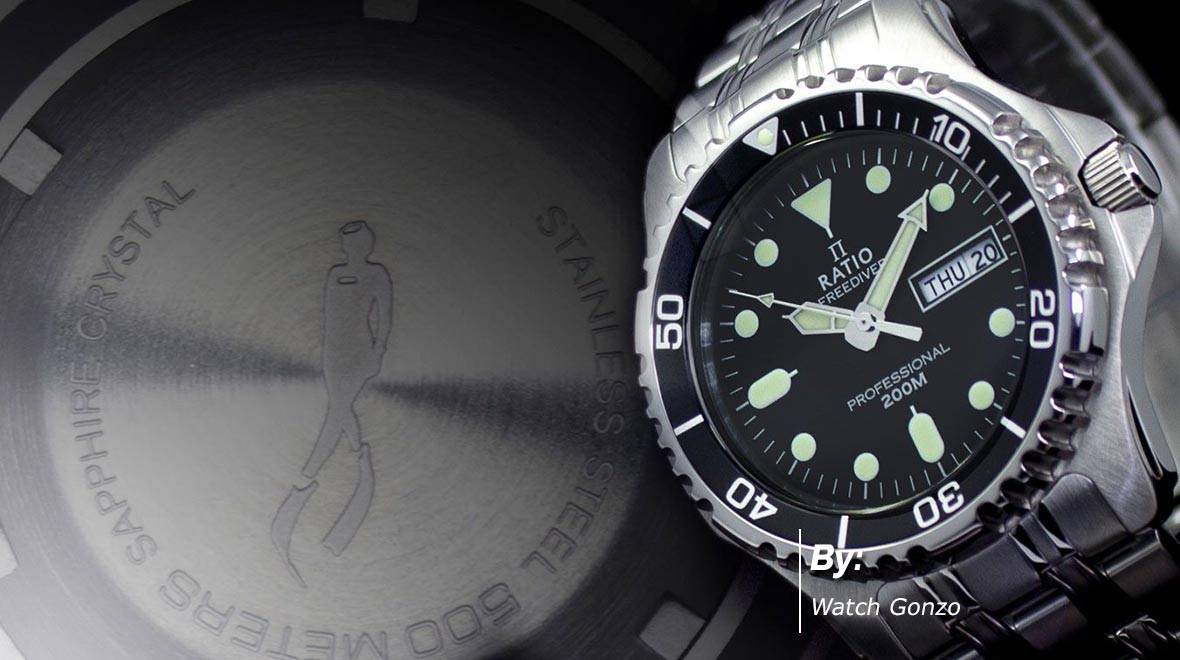

WORK-DESK MANOEUVRES: THE CLEANING BEGINS

Checklist

Ensure that you have the following tools handy if you are going beyond basic cleaning, which we’ll soon cover.

- Mechanicals: Need to be thoroughly cleaned once open. All of the parts should be cleaned from all traces of debris, residue and other contaminants. Brass and steel lose their edge unless cleaned properly from time to time.

Lighter fluid and methylated spirits (denatured alcohol) might corrode non-metal parts especially the shellac that retains the jewels. Avoid flooding the movement with either of these, just like you don’t immerse a gun in gun-oil in the name of cleaning.

Always fully disassemble the watch for the thorough cleaning. Cleaning it from the top takes nothing but distilled water and a piece of soft, cotton cloth. Wash and wipe it dry, that’s it! Any cleaning you perform inside the case or the movement must be thoroughly dried before putting the case back on. Use the air blower for the purpose. Use the peg wood to remove any fouling that has not been dissolved by the cleaning solutions.

The case, crystal, case back and crown must soak in the cleaning fluid (100ml warm distilled water and 2 drops of liquid detergent) for several minutes before you use the brushes to thoroughly clean the surfaces.

Use distilled water to thoroughly rinse the cleaning solution off. Dry it reasonably. Next, rinse with 99.9% pure isopropyl alcohol. It will dissolve any grease that warm detergent solution couldn’t and also any detergent remains.

Lastly, pour the specially formulated, commercial cleaning fluid on the parts to give them a final rubbing and blot them out. In case you got no blotting paper at hand, use microfiber paper towels.

The real game starts when you decide to give the movement its due service, which we will; discuss in details in the next part of this post.

- Quartz, Meca-quartz, Solar, Smarts & Digitals: Need to be thoroughly cleaned once open, just like mechanicals. The cleaning procedure is the same; only that for quartz watch, the movement just needs a dip (after removing the battery) in a small bowl containing the cleaning fluid. This will wash old oil, debris and dust out of the movement that will settle as small particles at the bottom of the bowl/pot. The lubrication process for meca/auto quartz movements we will explain in our next post. Also, try not to self-service a smart or Solar or a sensor-based watch internally. Leave the job to the authorised service personnel.

THINGS YOU MUST REMEMBER BEFORE/WHILE CLEANING YOUR WATCH

- Cleaning products like lye, ammonia, paint thinner and other harsh chemicals aren’t good for metals; even for stainless steel. Use any grease-cutting detergent or dish washing soap are perfect for removing accumulated dirt on glass and large metal parts. This will also preserve the finish of the respective parts.

- Do NOT try opening the case back and taking the movement out unless you are confident enough. Our suggestion, try these steps first with a watch that has gone defunct or if its loss won’t affect you at all.

- Never try to service smart watches internally on your own. Same applies to any watch within a sealed, compact module.

- Always open your watch in a reasonably dust- and moisture-free environment.

CONCLUSION: AT THE END OF IT ALL

Home watch repairs and maintenance is an area of much debate. While most are okay with just a gentle, external, periodic wipe with a cloth, some like to keep their lustre intact with soap water and soft brushes. And still, there are some looking for everything about their watches squeaky clean and freely rolling. For them, we bring some of the tips and tricks from all over the watch world, science and superstitions both. It’s up to you if you’d be courageous enough to try out the later.

Currently what we brought to you is the first step to the world of watch maintenance that introduces you to the very basics of watches and their maintenance tools and the initial cleaning procedures. Check back soon to read about and try some serious watch maintenance.

FAQ

Depends upon usage. Worn under normal urban environmental conditions, most watches – irrespective of its kind – will need frequent external cleaning. This means rubs and wipes with a cotton cloth; sometimes with lukewarm soap-water. A complete service can occur every 5 years, on an average.

Those moderately subjected to outdoors will need a complete service every three years and immediate external cleaning with distilled/fresh water after use. Even for quartz watches, for that’s roughly the lifespan of a battery. Solar watches can go a little further; if worn sparsely, might run flawlessly for as many as two decades.

It does and this is different from exposing your watch deliberately to water, sand or mud. Depending upon the level of heat or moisture or a lack of them, the maximum time, you should let elapse between servicing is 2 to 3 years. This will ensure that the O-ring rubber gaskets or the screw-down threads do not get compromised, which is adding life to the movement.

In general, watches with additional complications will require more frequent services than the basic ones. This is because more gears translate into more friction. Complications like perpetual calendars, split-seconds chronographs or minute repeaters comprise additional parts that are prone to damage if the oil dries. A complete service is recommended for them every three to five years, irrespective of whether you wear them frequently or not. Just take care that the service interval doesn’t extend beyond five years.

A proper service without repair or replacements will include:

- Disassembling

- Cleaning

- Oiling

- Polishing

Damaged components will be either fixed or replaced. Finally, the watchmaker will reassemble the watch and regulate/adjust it in several positions to make sure it runs well.