- June 25, 2022

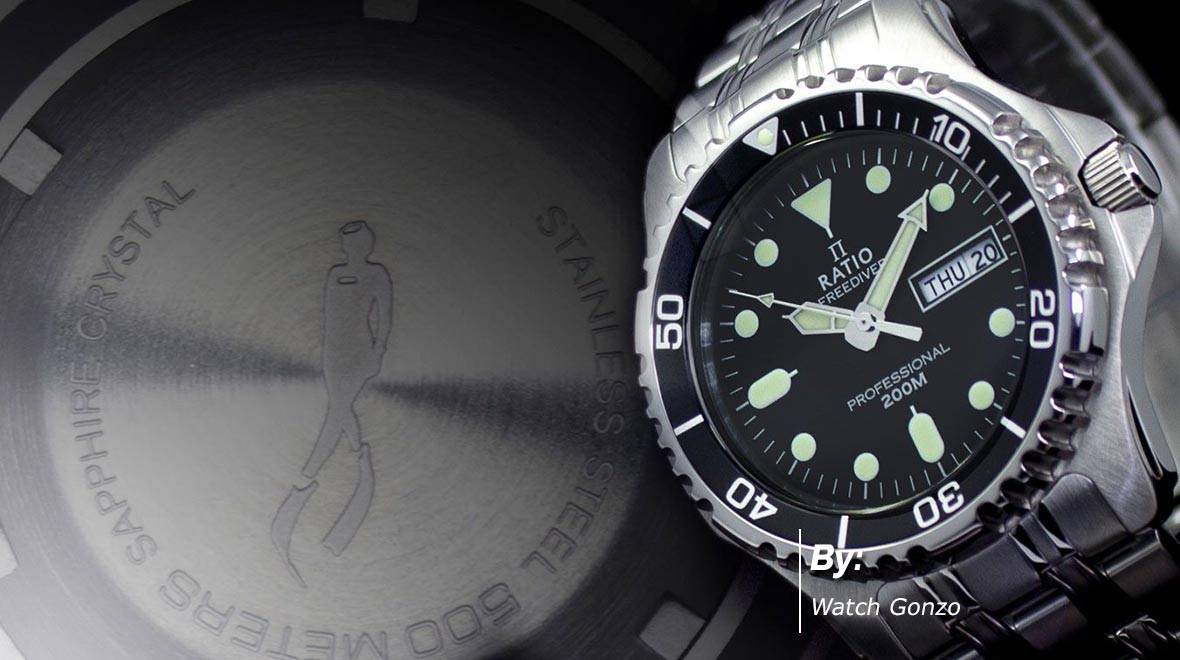

- Watch Gonzo

- 0

Introduction

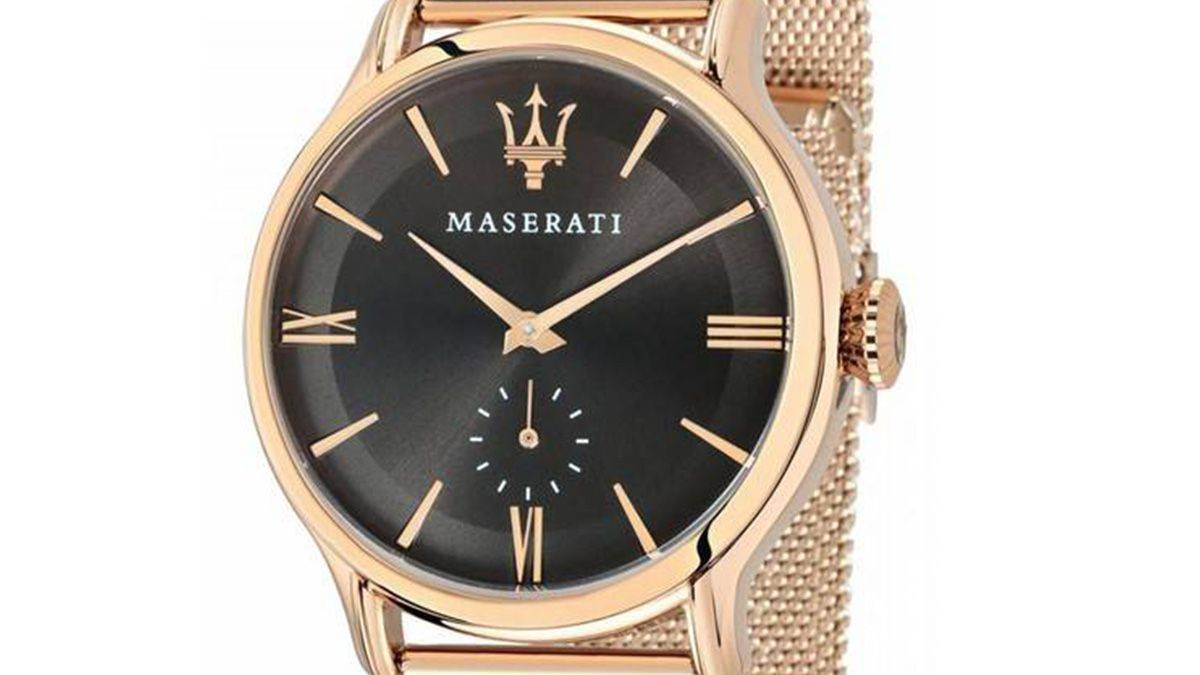

It doesn’t seem this ongoing debate concerning two of the most popular metals will meet its end any soon. You’ll find the ‘ Steel vs Titanium ‘ debates popping up here and there many moons after you’ve been through this piece. Besides, now that things are not like before, it turns the matter even more complicated! It’s becoming too much of a riddle. So, without further ado: Technological advancements and inventions in material sciences bred many different grades and types of steel and titanium. It means: You can’t be sure of your watch using a suitable grade of the material. Unless of course, you are getting it from a good, reputed brand. We will bring you a few watches like that from the reputed brands. They do a lot more than watches that sell just for the big brand names. Many times, they cost more than what they should, ideally.

As of now, we will be studying titanium and steel. This is because you want to understand the differences better. Else, you’ll not be able to truly verify if titanium is really better than steel and whether the coatings and hardenings are for real or just gimmicks that help to sell it better.

We will bring you a few watches like that from the reputed brands. They do a lot more than watches that sell just for the big brand names. Many times, they cost more than what they should, ideally.

As of now, we will be studying titanium and steel. This is because you want to understand the differences better. Else, you’ll not be able to truly verify if titanium is really better than steel and whether the coatings and hardenings are for real or just gimmicks that help to sell it better.

A brief look at Titanium

Titanium’s strength (or the myth/legend of it) that goes around is fascinating and confusing at the same time. Still, fact remains – ”

being famous always make people act nice to you”.

Even if there’s someone who had a bad experience with titanium previously might hush up his/her complaint due to self-doubt, thinking they must be going wrong somewhere.

Let’s see first if the fame that titanium earned is justified.

Still, fact remains – ”

being famous always make people act nice to you”.

Even if there’s someone who had a bad experience with titanium previously might hush up his/her complaint due to self-doubt, thinking they must be going wrong somewhere.

Let’s see first if the fame that titanium earned is justified.

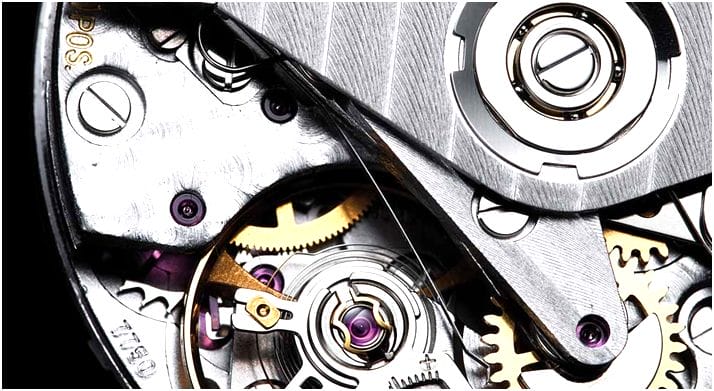

- Titanium is a paramagnetic material i.e. it is not affected by magnetic fields to a great extent. Even MRI machines have no effect on them. Paramagnetic materials tend to get weakly magnetized when within a very strong magnetic field. Good news is – they quickly demagnetize as soon as they move out of the magnetic field.

- Titanium is considered to be one of the strongest metals that’s lightweight, corrosion resistant and hypoallergenic. But then again, why didn’t Tungsten, – in terms of tensile strength – the strongest among all natural metals (withstanding up to 142,000 psi) couldn’t replace Titanium? In terms of impact strength, Titanium beats tungsten, which is a brittle metal that shatters upon impact. This is why Titanium wins with a far lower tensile strength of 63,000 psi. Its heat, water and salt resistance makes for an ideal material for a variety of applications, ranging from jewelry and medical equipment to aviation and naval engineering.

- Titanium has a Vicker’s rating of 350 HV (approx.) while steel scores just 150-200 HV. But titanium scratches easier than stainless steel, or that’s what we believe. The scratches actually form on the layer of oxide that forms on the surface. This can be treated fast, nice and quick to return the shine.

The classifications of Titanium Watches

Pure titanium by itself is strong and corrosion-resistant. The deep gunmetal luster of titanium is like none else’s! Painting titanium has always been (and still is) a blasphemy of the highest order! So why are there titanium alloys? Other metals mixed with titanium don’t affect its strength or corrosion-resistance. Instead, they impart greater flexibility and malleability to titanium. The titanium alloys, therefore, find more applications than pure titanium. Titanium alloys will typically contain very small percentages of other metals. These will be: aluminum, vanadium, molybdenum, niobium, zirconium, tantalum, manganese, chromium, iron, cobalt, nickel and copper. So, we appear at the grades.Grade 1:

This commercially pure/unalloyed variety of Titanium is the most soft and ductile among all the grades. It has the greatest formability. Its excellent corrosion resistance and weldability is much appreciated in marine and chemical industries. Fabrication jobs for electrical/electronic equipment too go very well with this grade.Grade 2:

Most widely used light weight, pure alpha titanium alloy of moderate strength, reasonable ductility and excellent corrosion resistance. It is also a commercially pure variety of titanium and nearly as strong as Grade 3 and Grade 5 titanium. It is stronger than Grade 1, It is the most widely used titanium variety in watches other than Grade 5 .Grade 3:

General purpose, commercially pure titanium with an excellent strength to weight ratio and high corrosion resistance.Grade 4:

Commercially pure Grade 4 is the highest-strength, unalloyed Titanium. It contains high amounts of oxygen, yielding extra high strength, excellent corrosion resistance and good formability and weldability.Grade 5:

An alpha-beta titanium alloy, it’s other name is Ti 6Al-4V . It has 6% aluminum and 4% vanadium into the mix and used in high-priced watches, It is the most commonly used titanium alloy for medical, marine, aerospace and chemical processing industries and used in the making of aircraft turbines, engine and structural components, fasteners, high-performance automatic parts, marine instruments and sports equipment.Grade 6:

Its another name is Ti 5Al-2.5Sn . It is a non-heat treatable alloy with good weldability and stability under high temperatures. Apart from a high strength and good corrosion resistance, it doesn’t deform under high temperatures. Hence, it finds maximum usage in aircraft and airframe applications.Grade 7:

With almost similar physical and mechanical properties as Grade 2, Grade 7 bears miniscule differences with it. This grade responds very well to welding and fabrication processes. It is also extremely resistant to corrosion (especially from acids) due to its Palladium content.Grade 11:

Similar to Grade 1 in its physical and mechanical properties similar to Grade 1, it is also known as Ti-0.15Pd . Pd denotes it has Palladium content. This too has an enhanced corrosion resistance apart from excellent ductility, cold formability, toughness against impacts and an excellent weldability.Grade 23:

The Ti 6 AL-4V ELI or surgical titanium is largely used to manufacture surgical equipment. It is a purer version of Grade 5 titanium alloy. It can be easily molded, cut, coiled and drawn into wires. In its properties, it is same as the Ti 6AL-4V – equally light-weight and highly tolerant to damages. It has superior biocompatibility i.e. tolerated very well by living bodies. It is used for making orthopedic pins, screws, cables, ligature clips and staples, artificial joints and cryogenic vessels.Notes: The unusual Titanium:

Grade 12: :

This alloy is also called Ti 3 AI 2.5 . It has the best weldability among all titanium alloys and retains its full strength at high temperatures. This grade is unique for weighing heavier than the other titanium alloys. It is used mostly for hydrometallurgical applications, high-temperature chemical manufacturing and in marine and aviation componentsSuper Titanium:

Citizen refers to their proprietary version of Titanium as space-age . It’s 5 times more scratch-resistant than normal titanium. It’s 40% lighter than stainless steel too! The first watch made out of solid Titanium in 1970 was from Citizen. Super Titanium is lighter and feels smoother on the skin. It has added strength and hardness, making it a superior watch material than stainless steel. Citizen treats Titanium with Duratect , their own version of surface-hardening technology. All Citizen Titanium watches are actually Super Titanium.The classifications of Steel

| Element | Purpose |

| Carbon | High carbon content makes the steel more durable and longer-lasting compared to other alloys. Food-grade utensils and cooking utensils make most use of high-carbon steels. |

| Chromium | Chromium increases corrosion/stain/tarnish resistance. |

| Nickel | For an improved ductility, formability and weldability and corrosion-resistance. Nickel is the metal that turns stainless steel into a versatile alloy. |

Steel and its four groups —

i. Carbon steels:

Contain trace amounts of other metals besides carbon(0.3% – 0.6%>) and Iron. It makes up for 90% of steel production. Up to 0.3% carbon content makes low carbon or mild steels, 0.3–0.6% for medium carbon steel and more than 0.6% carbon for high carbon steels.ii. Alloy steels::

Additional metals (vanadium, silicon, nickel, manganese, copper and chromium) present enhance the strength, corrosion resistance and ductility of the steel. It also makes machining easier.iii. Stainless Steel:

Contains 10-20% chromium besides small percentages of nickel, silicon, manganese and carbon. Let’s break it further.a. Austenitic stainless steel:

It contains a lot of chromium and hence, it’s more corrosion-resistant. It’s non-magnetic by nature but turns magnetic if it undergoes cold forging process. Its nickel content determines its susceptibility towards magnetism; higher it is, more it is resistant to magnetic fields. But high nickel percentage may not always be a practical thing. There are two main grades – 304 and 316 – to it. The Grade 304 bears higher tensile strength ( ~ 621 MPa/90 ksi) and a higher melting point (870°C/1598°F) compared to grade 316 stainless steel (579 MPs/84 ksi; 800°C/1472°F). But 316 beats 304 because it is more resistant to oxidation along with from corrosions; from natural elements, industrial and domestic chemicals and corrosives alike. The 316 stainless steel (especially with molybdenum content) is therefore; the most desirable stainless steel for maritime and medical instruments and for daily wearables. The 304, on the other hand contains approximately 18% chromium and 8% nickel. There also remains present small amounts of carbon and manganese. These two prevent oxidation and help maintain its strength and durability. It also makes cleaning/sterilizing easy.. That allowed 304 to get into a large number of fields. It finds profuse usage in medical equipment, household utensils and industrial applications; in machinery parts, fasteners and in exhaust manifolds. Any architectural, exterior accent will most probably be a 304 stainless steel structure, by itself or at the core. A variant to the grade 316 is the 316L, the low-carbon version. This one mixes chromium (16–18%), nickel (10–12%) and molybdenum (2–3%), with small (<1%) quantities of silicon and phosphorus. It also contains traces of sulfur. The molybdenum makes it corrosion-free. Cold working gives 316L a higher yield and more ensile strength. On the flip side, the steel develops magnetic properties that need demagnetization.Notes: The unusual steels

- A further variant is the 316LN that is still less prone towards turning magnetic but is difficult to procure.

- Lastly, we arrive at 904L steel, made famous by none other than Rolex! They use this austenitic stainless steel for its molybdenum and copper content. These two give it superior resistance to pitting and crevice corrosion from acids and chlorides. It has a low carbon content, which makes it resistant to sensitization by welding besides preventing inter-granular corrosion.

b. Ferritic Stainless Steel:

It is the second most common type of steel alloy with lower nickel content. Magnetic properties are present. It has two different grades – grade 430 and grade 434.- Grade 430 stainless steel isn’t as strong as the 304 or 316 (and their variants). But it’s immune to nitric acid and – strong enough to suit any heavy-duty application. –

- The grade 434 is higher on tensile strength, max operational temperature and pitting resistance compared to grade 430.

c. Martensitic Stainless Steel:

The grade 420 is slightly less resistant to corrosive chemicals than the austenitic and ferritic varieties. Still it is enough resistant to alkalis, mild acids and oxidations. It’s strengths are its great tensile strength and therefore, a huge impact resistance. A layer of protective polymer gives it an improved corrosion-resistance.iv. Tool steel:

The best type when you are making cutting/drilling instrument or equipment. There is tungsten, molybdenum, cobalt and vanadium in the mix. They increase the both heat resistance and hardness, helping to retain shape for multiple, heavy usages. Hand tools (chisels, hammers, combat knives etc.) mostly use tool steel as the preferred material.So, who scores more as a watch material?

Answering this question with a straight “Yes” or “No” would be not just wrong but very wrong! The strength or suitability of a material depends upon the purpose it will be used for. If ‘X’ does the job, it’s highly unlikely you’ll go for (X+1). When you need high yield strength, choosing a material with high compressive strength is foolish. It’s the purpose you are using the material for that determines if that material is going to prove better than another one. Titanium watches, by itself, is a highly durable, corrosion-resistant and strong metal. It is roughly 30% stronger than stainless steel and weighs less. Its another benefit is it does not corrode, rust or trigger skin allergy. In its alloy forms, it exhibits even greater malleability and flexibility in addition to the strength. With special treatments, it can be hardened further, opening doors towards many more different applications, spanning over many different industries. But Titanium oxidizes and takes on a whitish appearance if exposed to halides; specially chlorides. It also doesn’t take that high shine unlike steel or aluminium. This is where a lot of people might ignore the weight to strength ratio and run after the glitters. Therefore, watch manufacturers picked out Grade 2 and Grade 5 Titanium, which are less prone to gather scratch. The issue of Titanium being more prone to scratches thus seems to arise from low-grade watches.A little extra info

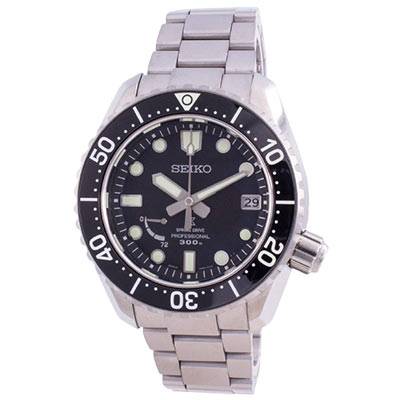

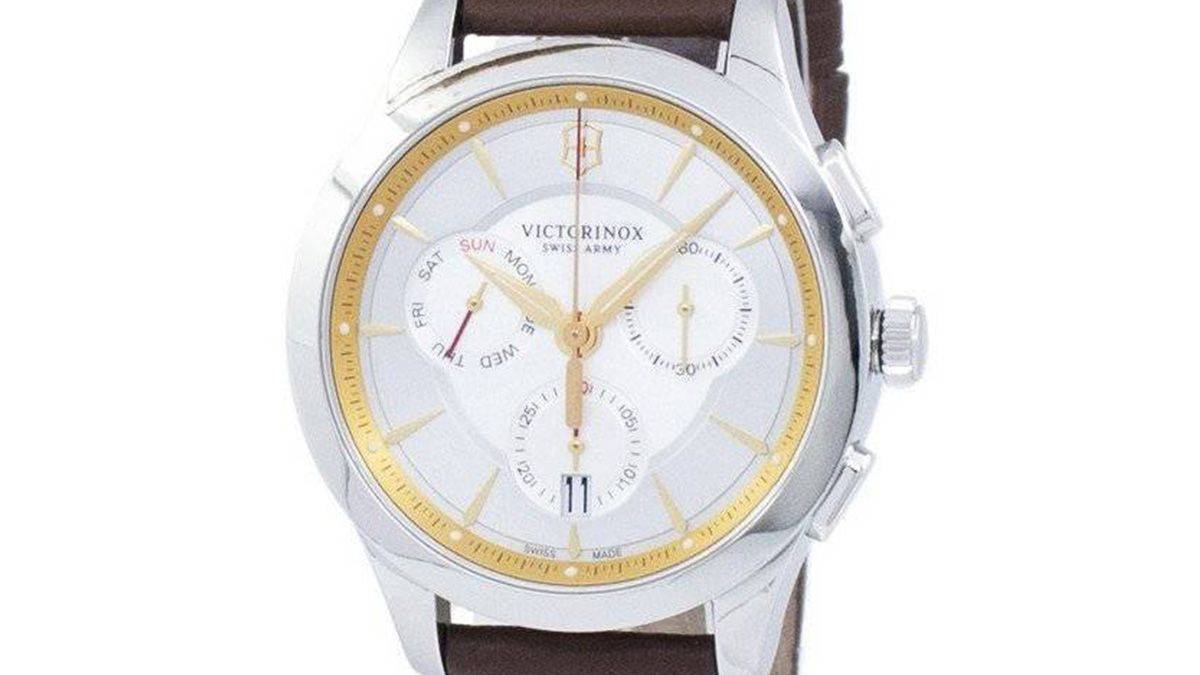

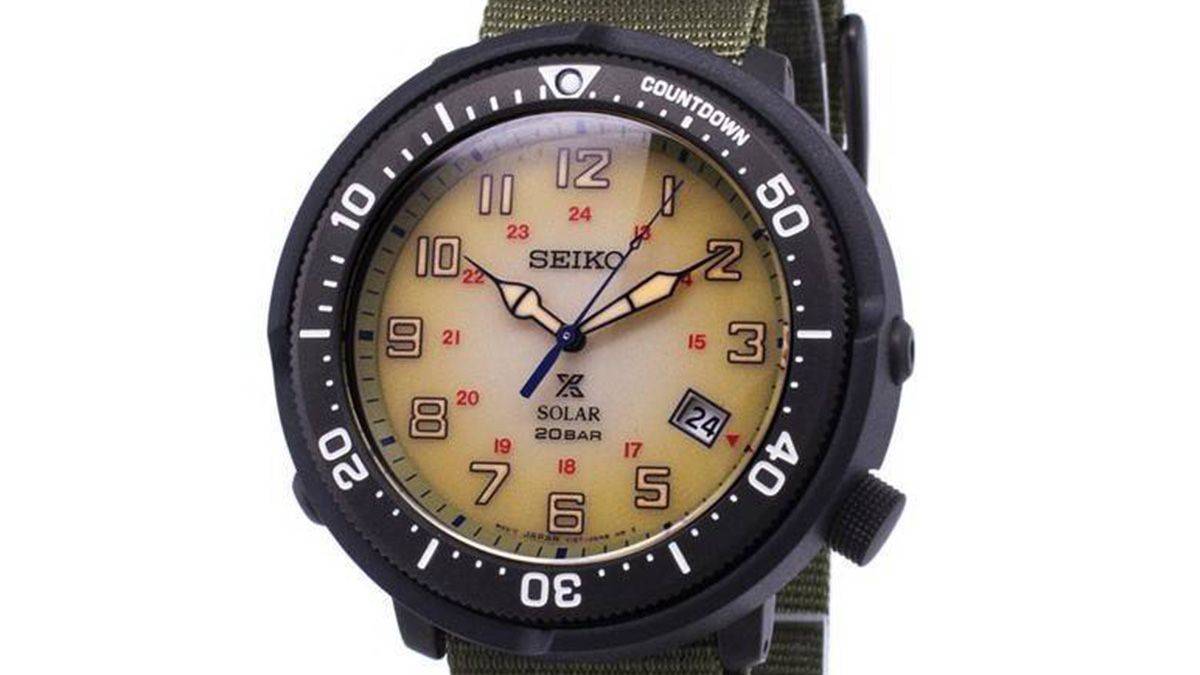

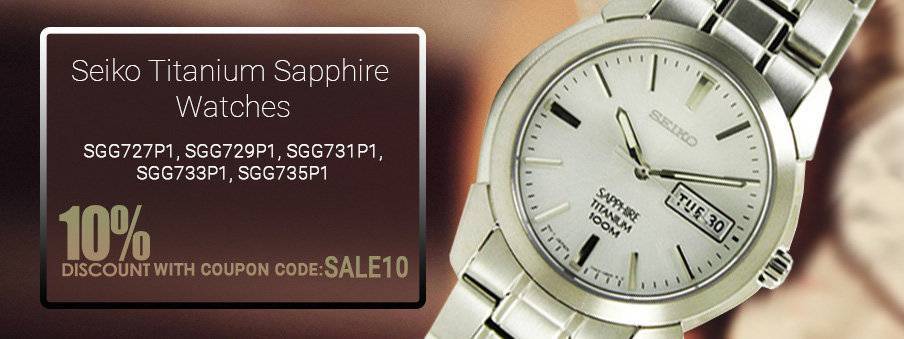

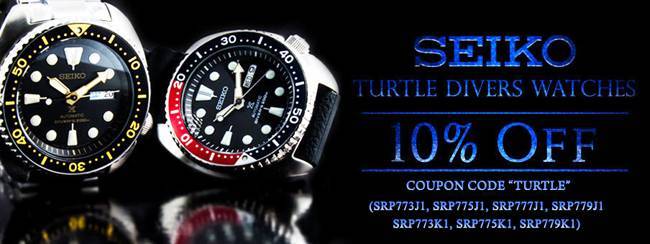

You got to understand something here. Titanium being a highly active metal makes working with it a challenging task. By no means may you use Titanium as a plating agent – whether electroplating or using some other method. It is too reactive for these processes but most of us do not know that. Another thing is: Most think titanium as a precious metal costing way more than steel, so they fall for advertisements like ‘ Titanium-plated body’ and the likes. And here starts the problem. A titanium-finish is not titanium; therefore, no way it’s going to perform like the real thing. Titanium alloys are significantly stronger than many steels and the finest titanium alloys will always outperform low-grade steels. At the end of the day, you’ll see Titanium accumulating much less scratches than stainless steel. And the good news is: Scratches can be removed from Titanium far easier than from upon stainless steel or in that case, any other metal. Do we know now which of the two is better overall? To stay impartial, I’d say it really depends upon your needs and budget. But if your budget is more than a hundred dollars, a titanium watch is what you should go for. There are plenty, starting from Skagen Henriksen to the Seiko Prospex LX Spring Drive Professional to pick from and guess what! At times, you do not even need to pay the prices the manufacturers ask for!10 Titanium watches you should check out without fail!

leave your replies below . State which one from the above watches you’d like to go for the most and reasons behind it. v

Post Views: 1,423

Tags: Titanium watches