So we return to the topic again. Gonzo went on about the 46 years of experience backing up Seiko’s production quartz watches. He started on the finer details a bit and was about to raise his praises about the greatness of the movements (his ‘hots’ for the 9F showed), when suddenly, there was a knock. Gonzo could be frustratingly silent if his mood goes off; instead, a few suggested articles guided the way. The 9F rates at +10 seconds per year (at worst) and +05 seconds per year (at best). It also hosts other technical improvements. Aimed towards simplicity, reliability and accuracy, they often rate a +03 seconds for some! Even, +4/-2 seconds, although not in large numbers – which means: They are as good as the GS mechanicals and vice versa.

Here, things really came to a halt. Stalemate!

Gonzo, in the meantime, recovered with aid from more-than-moderate, finely ground chocolate dust sprinkled upon strong and frothy dark coffee and a couple decent smoke. But this time, he forced through several online information about movement designs, which clearly demonstrate the Grand Seiko’s dualistic nature.

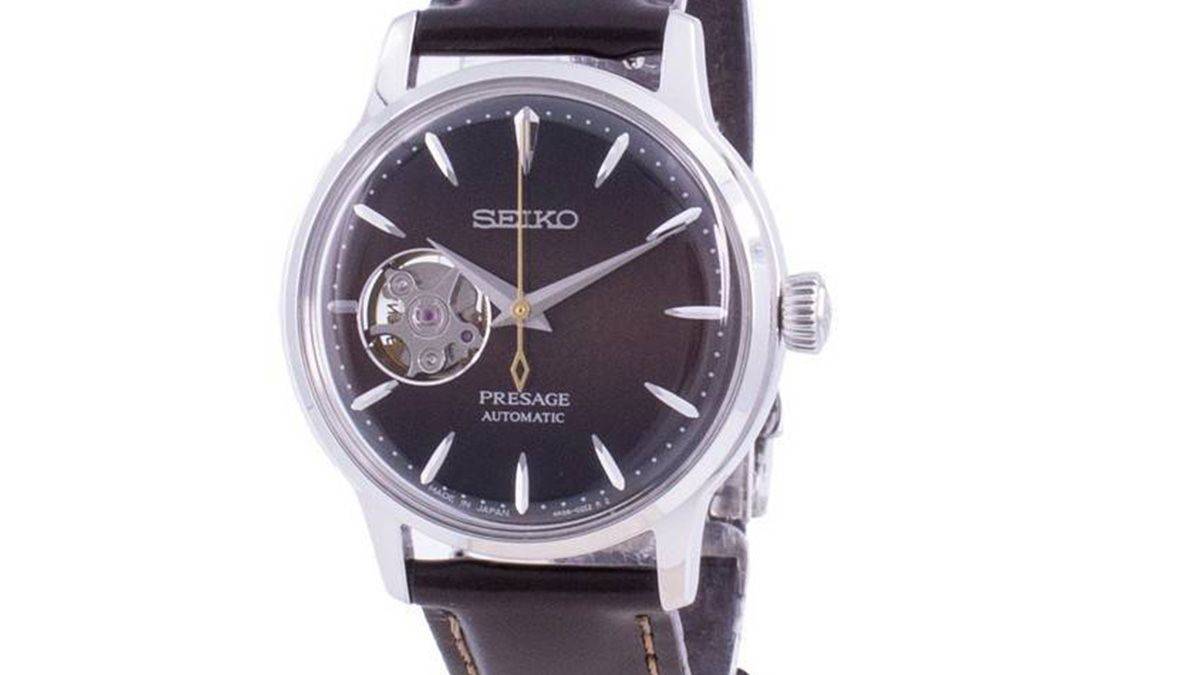

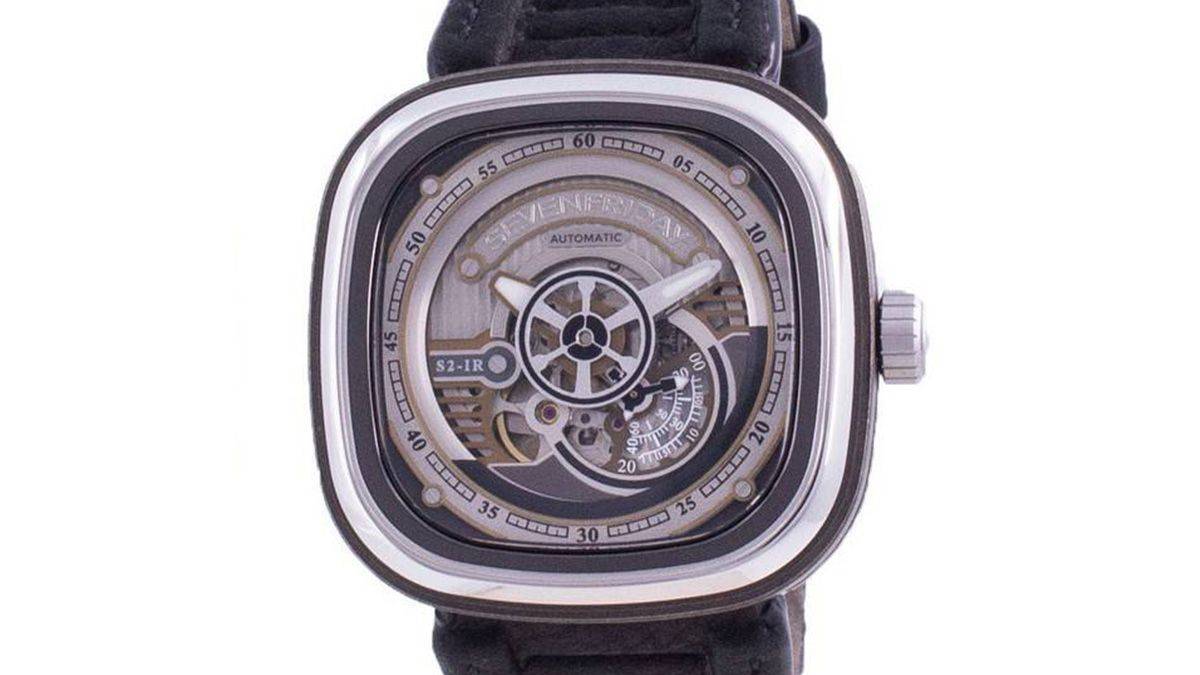

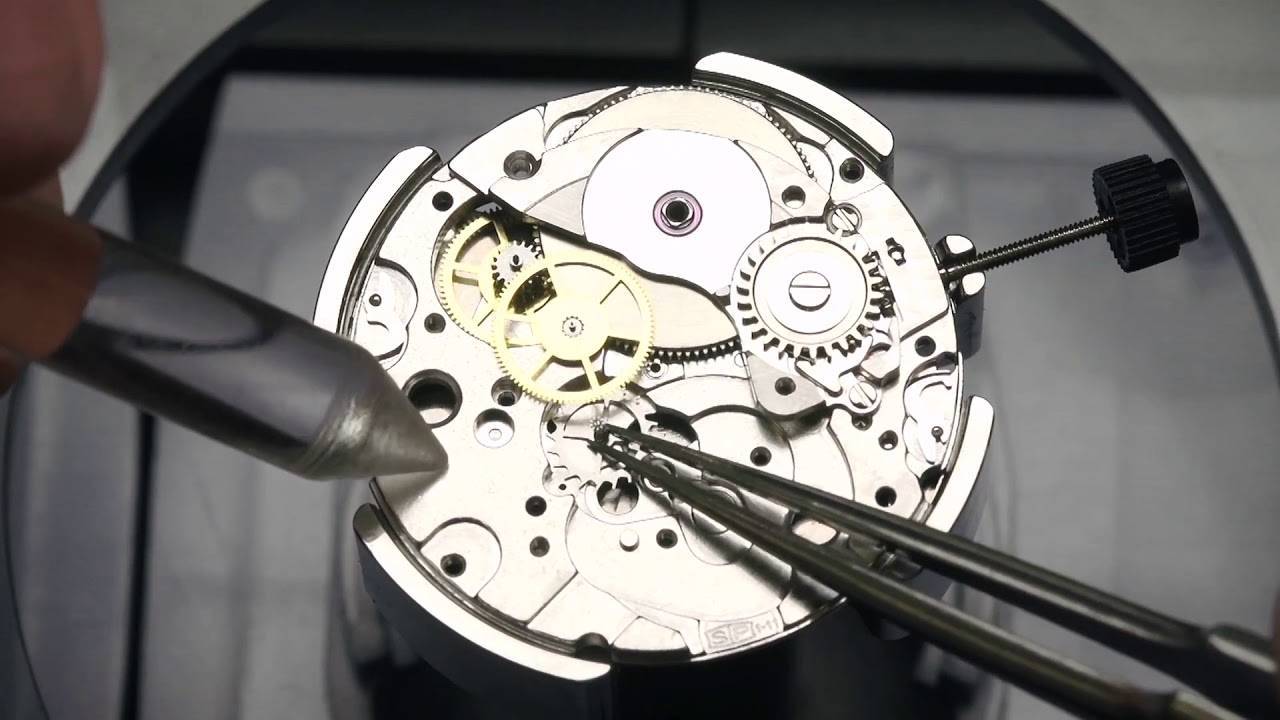

A GS never uses silicon components but brings new, innovative twists with traditional materials that surpass competitions. So pallet forks and escape wheels – while fully steel – are MEMS manufacturing offering a superior precision. They are lightweight due to their fine skeletonising.

The hairsprings and mainsprings are made from Seiko’s custom metallic alloys created only for this purpose. The SPRON has enhanced properties than its competitors.

These two great technological improvements brought in the third – the legendary Hi-Beat was born. Seiko used special oil-retaining grooves inside to reduce increased wear and tear. High frequency escapements are more prone towards it; so the advancement followed. The 9S5 and 9S6 lines of movements, specially.

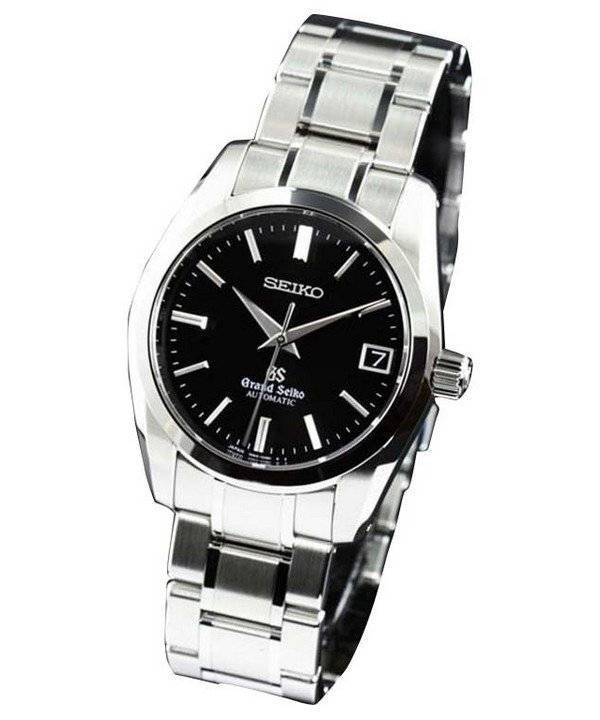

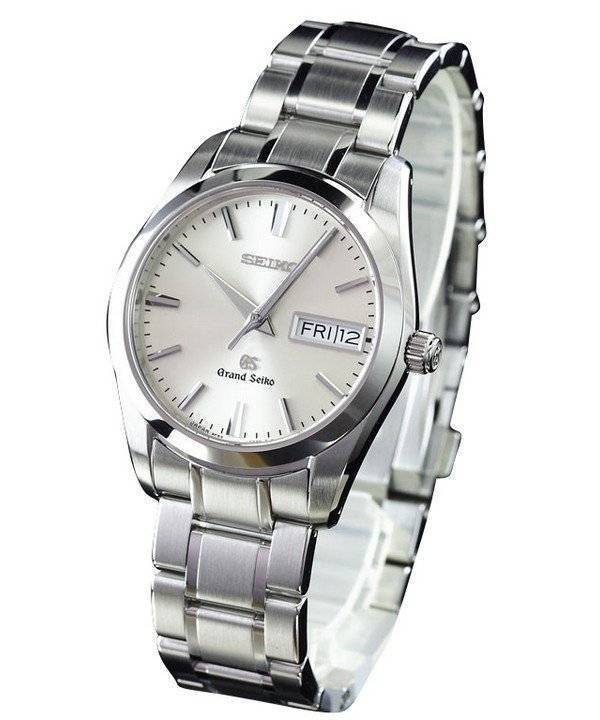

Grand Seiko still goes about the traditional watch polishing, assembly and adjustment methods, where every part of a Grand Seiko is taken care of individually. Master watchmakers applying the zaratsu technique – it’s said – is quite a sight to see!

That’s the historical Japanese sword polishing ways applied to add the polish. Once only a togishi-art, it adorns every surface of the Grand Seiko, all hand polished to extremely fine finishes to its assembly.

Or, take adjustments and testing! There’s an additional 6th position – which is one more than the COSC standards and best compensates for the effects of gravity! It takes 17 days for a GS to complete all. JLC and a few elites in its own rank only go through that pain!

Note: Here, we just took a simplified view of a bunch of impressively tight constructions and tolerance levels. Spreadsheets might reveal the real wonders in long lists of technical achievements, but to understand the Grand Seiko, first, appreciate its human elements. It doesn’t go into every other watch.

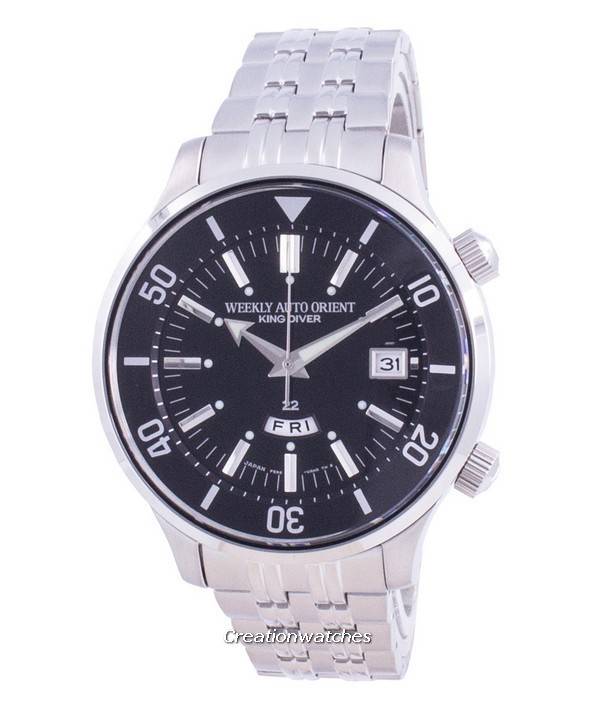

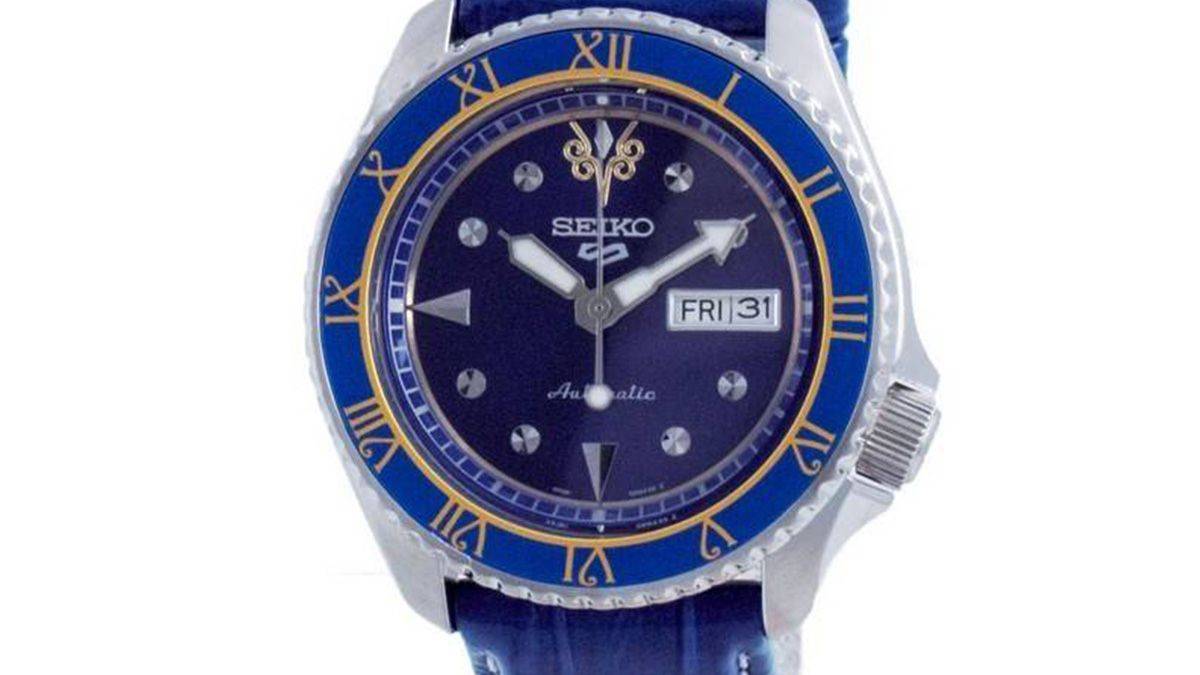

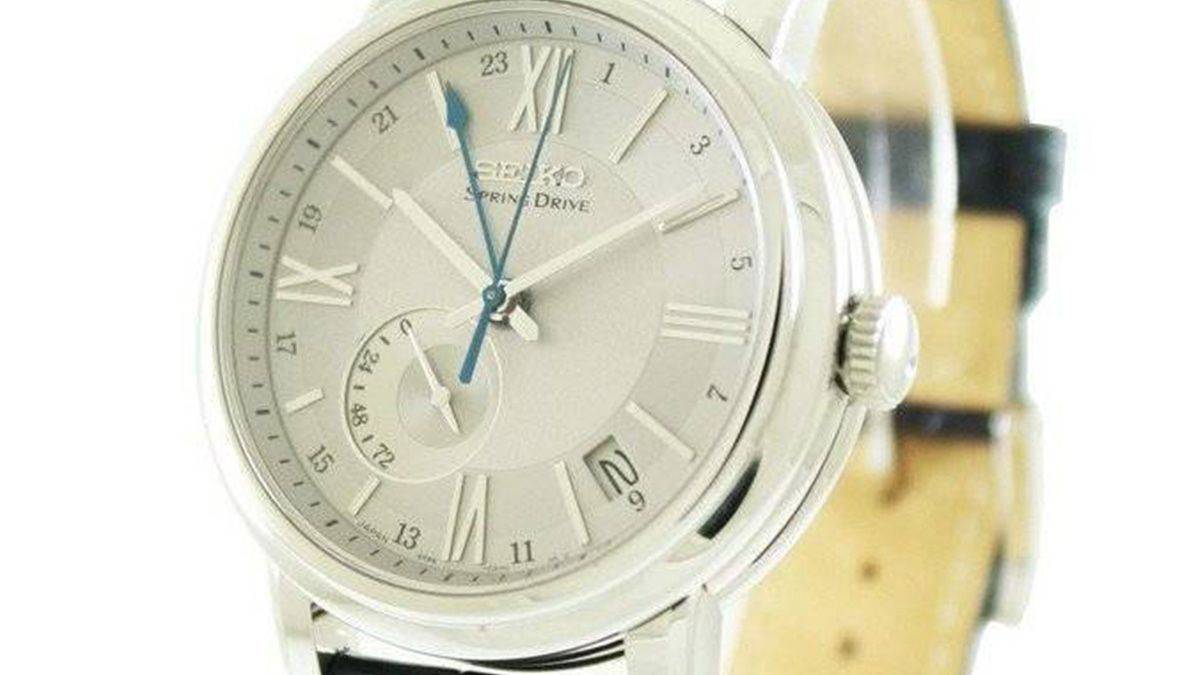

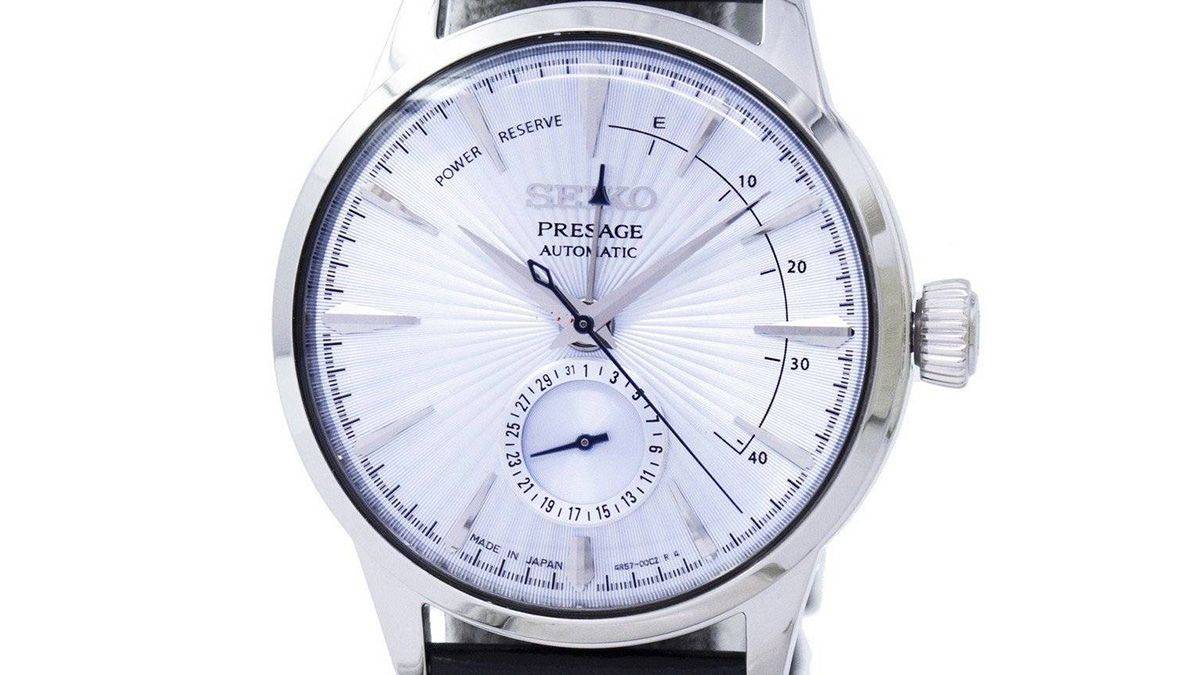

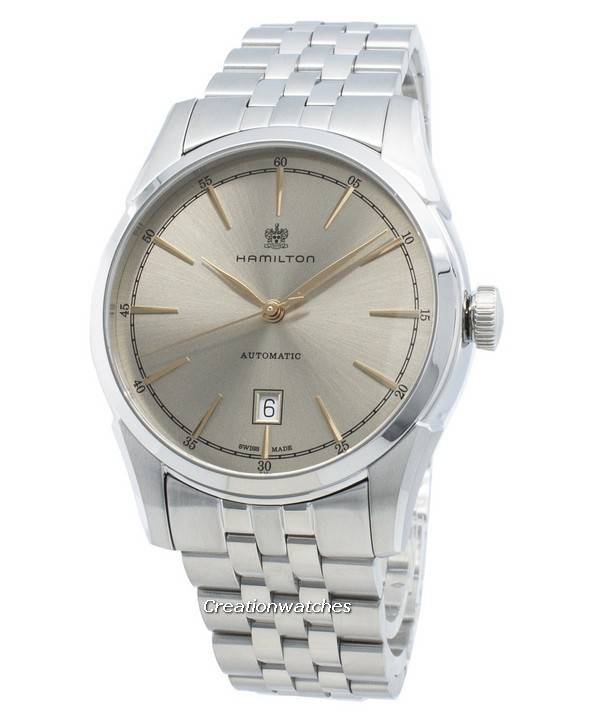

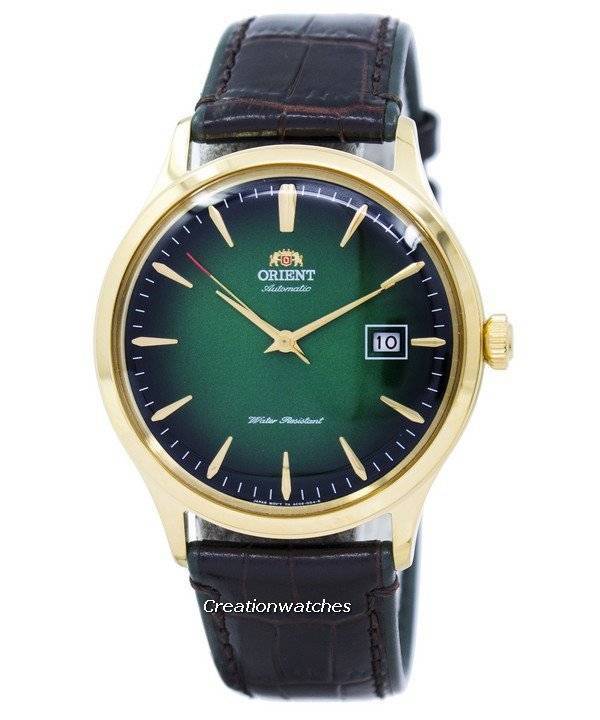

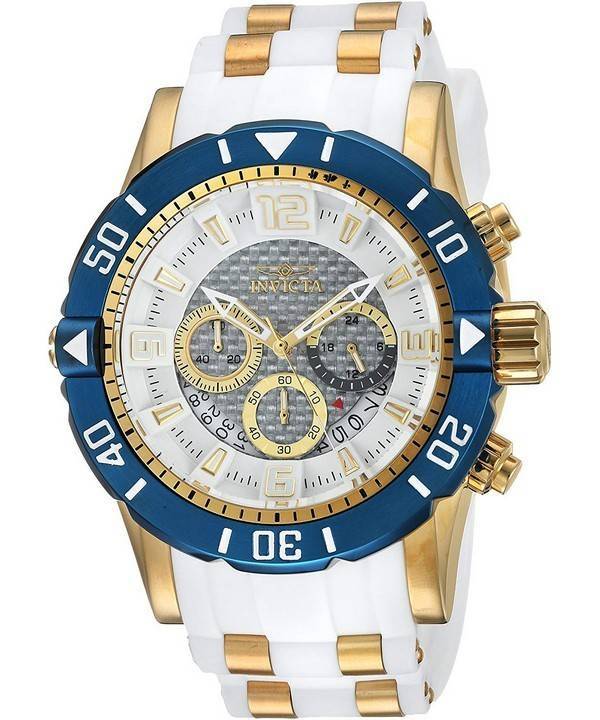

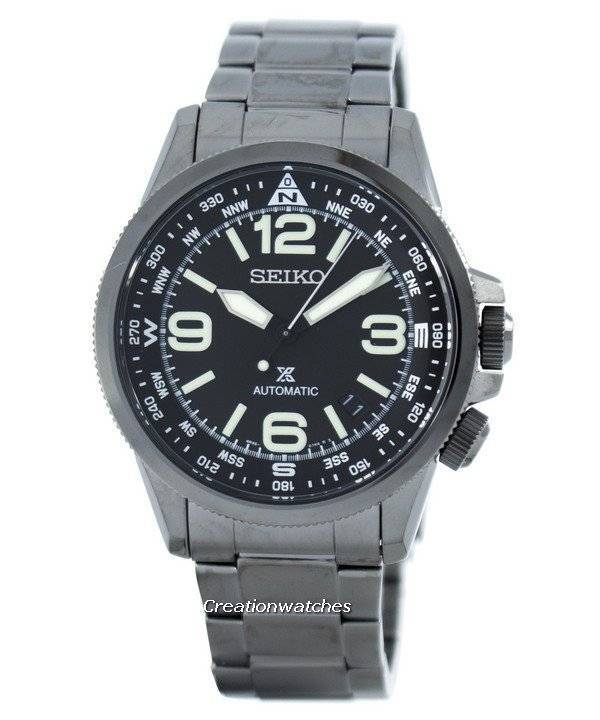

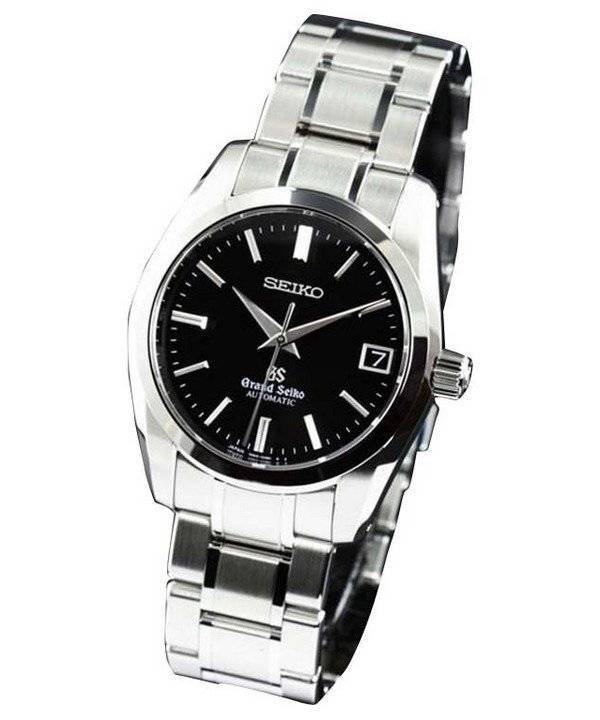

Watch(es) mentioned in this post are listed below. Click to see details and buy them:

- https://www.creationwatches.com/products/seiko-japan-82/grand-seiko-quartz-sbgt035-3702.html

- https://www.creationwatches.com/products/seiko-japan-82/grand-seiko-quartz-sbgt037-watch-3005.html

- https://www.creationwatches.com/products/seiko-japan-82/grand-seiko-automatic-sbgr051-mens-japan-made-watch-2209.html